aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

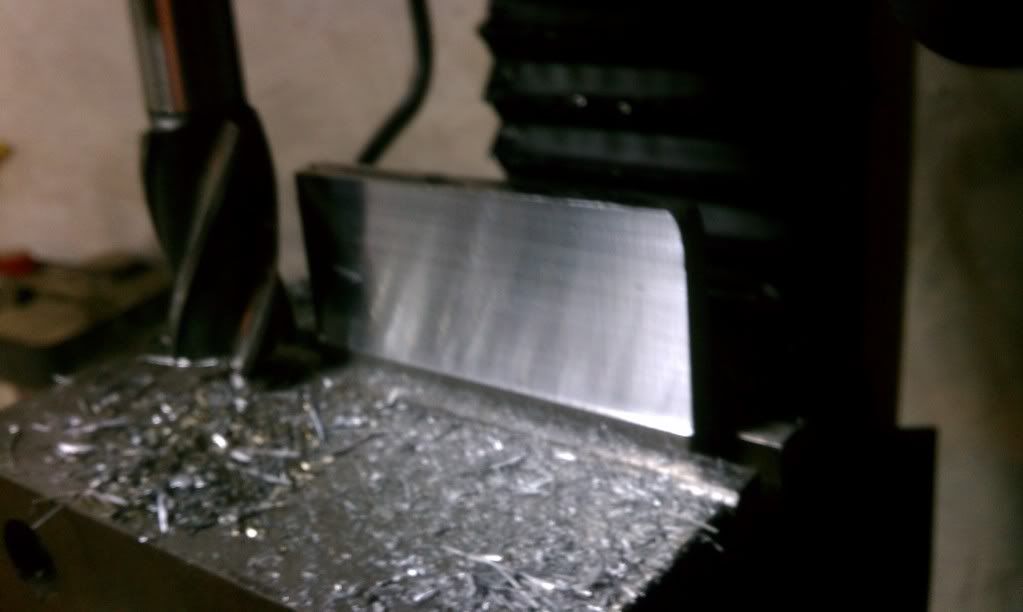

Well I got my G0704 mill today and the steppers and drivers. Im waiting on a conversion kit from arizona video on you tube to finish the pkg. I made a couple of passes with the mill today and can tell right away im for a learning cure. This mill is no where near as ridgid as my bridgeport. Im hoping that after getting to know it a little better, and getting the right speeds and feeds will improve upon the finish, time will tell..

any one play with one of these? I could use some honest insight...

any one play with one of these? I could use some honest insight...