maverick

Well-Known Member

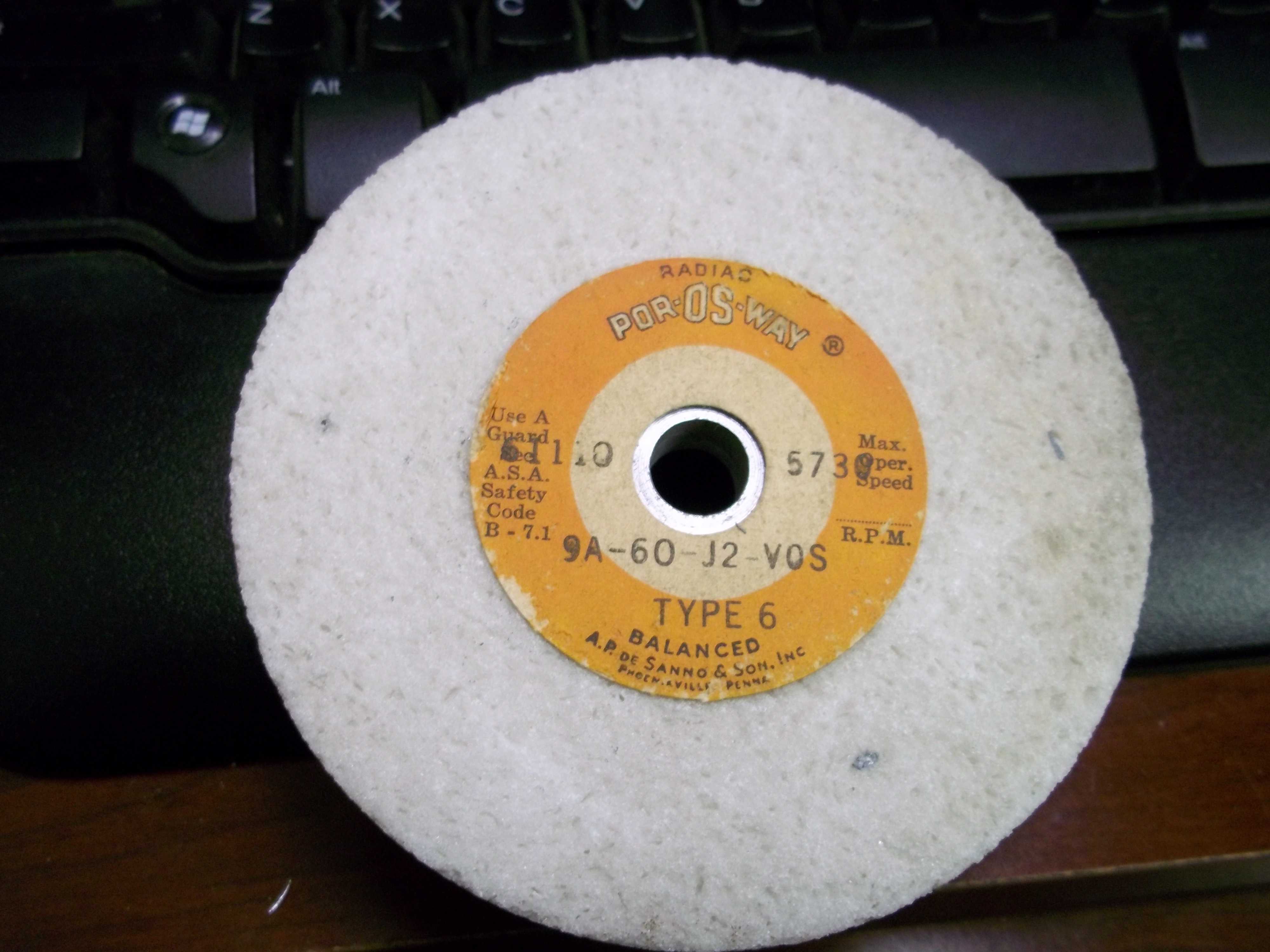

A 2 part question here. I have a dozen or so of these wheels and I think they fit a

Gorton cutter grinder, does anyone know for sure? The size is OD 4", width 1 1/4' hole 7/16

raised face 1/2'.

By mikeatmaverick at 2012-04-19

By mikeatmaverick at 2012-04-19

2nd question, does anyone want them for the cost of shipping? They appear to be unused and in

good shape and I'd like to find a good home for them.

Maverick

Gorton cutter grinder, does anyone know for sure? The size is OD 4", width 1 1/4' hole 7/16

raised face 1/2'.

By mikeatmaverick at 2012-04-19

By mikeatmaverick at 2012-04-19

2nd question, does anyone want them for the cost of shipping? They appear to be unused and in

good shape and I'd like to find a good home for them.

Maverick