R

Rog02

Guest

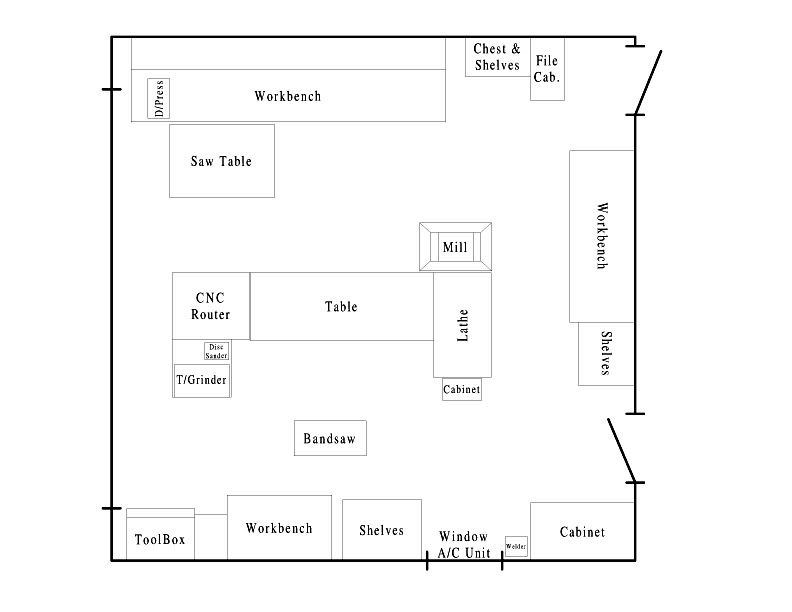

I am new to the model engine building, but have considerable experience in metal fab work as it pertains to aircraft and race car construction. The disc sander is an invaluable piece of equipment in my shop and the belt grinder is not far behind it.

When it comes to the belt grinder machines, the blade smiths have a pretty good handle on them and there are many plans available.

http://groups.msn.com/HomeorshopmadeGrinders/links.msnw This site is dedicated to homebuilt grinders of all types and much good information is available.

http://forums.dfoggknives.com/index.php?s=8f5dc505c6fd56bb74f4ea92e07df240&showtopic=4436&st=0

Another forum in which "Deker" chronicles his KMG clone build. Material list and many photos as he worked his way through it. A well documented build.

When it comes to the belt grinder machines, the blade smiths have a pretty good handle on them and there are many plans available.

http://groups.msn.com/HomeorshopmadeGrinders/links.msnw This site is dedicated to homebuilt grinders of all types and much good information is available.

http://forums.dfoggknives.com/index.php?s=8f5dc505c6fd56bb74f4ea92e07df240&showtopic=4436&st=0

Another forum in which "Deker" chronicles his KMG clone build. Material list and many photos as he worked his way through it. A well documented build.