vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

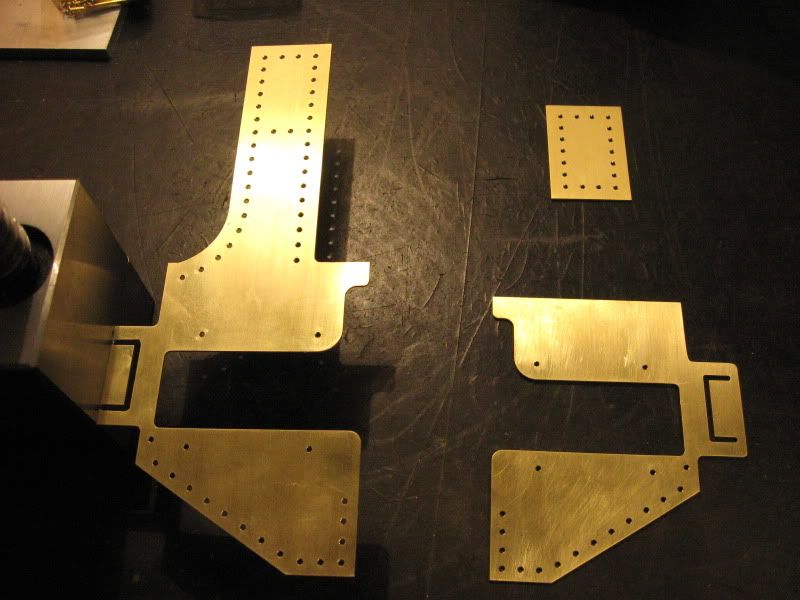

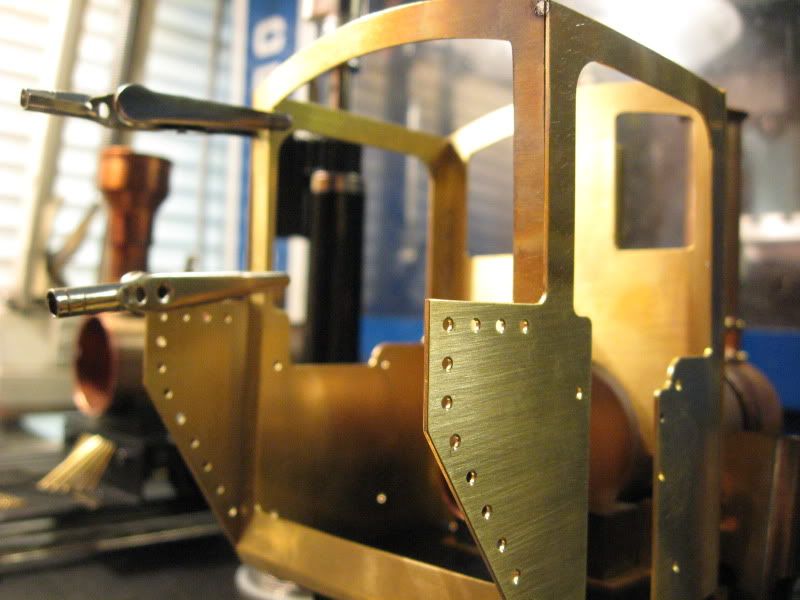

Thanks! I'm enjoying building these. Zeep motivated me into making these two parts this weekend.

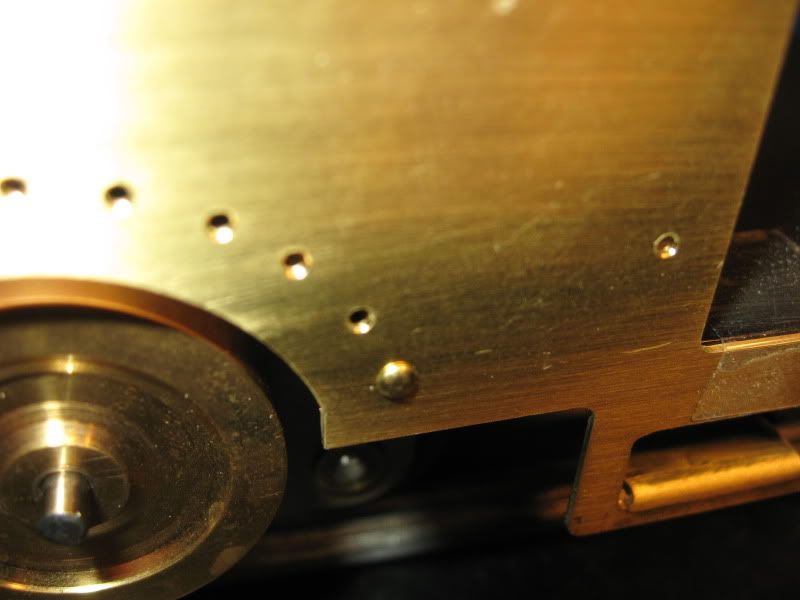

Oh yeah, that part was lightly scrubbed with a 3M or 'scotchbrite' pad.

Oh yeah, that part was lightly scrubbed with a 3M or 'scotchbrite' pad.

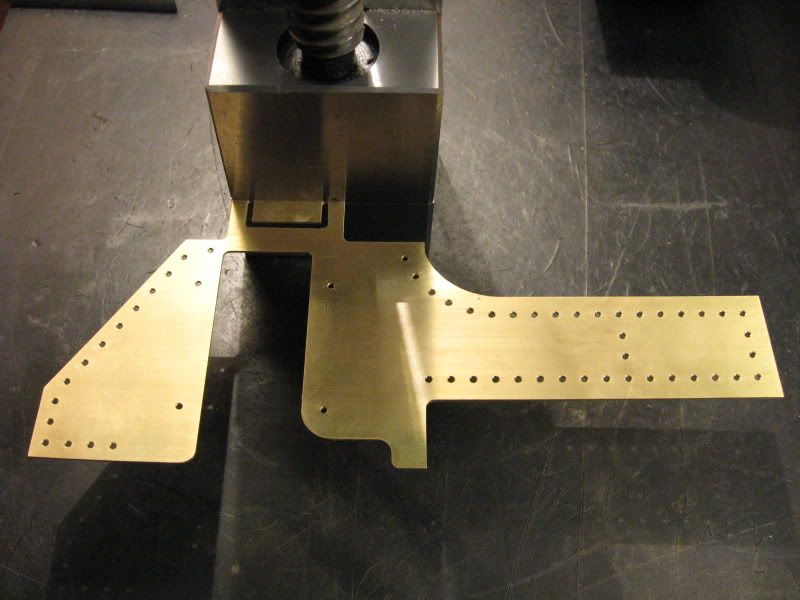

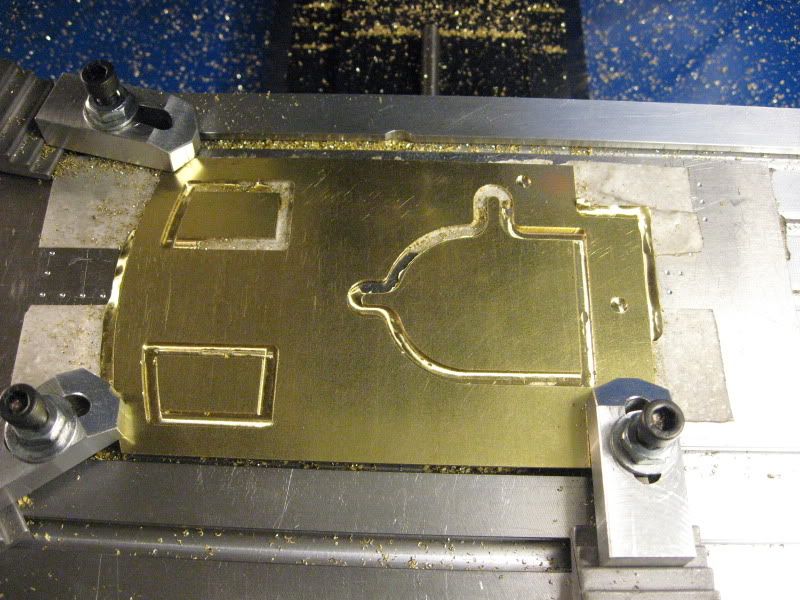

Yes, these two parts are the only time I've ever used superglue to hold a part. Usually it's doublesided tape, clamps, or softjaws, if I can't just drop them into a vise... while glue is more expensive than tape, it seems to work well.Deanofid said:What did you use to hold it to the fixture plate? Super glue?