xlchainsaw

Well-Known Member

- Joined

- Apr 22, 2008

- Messages

- 98

- Reaction score

- 3

ive been a member here for some time mostly just reading and now this section has been added i may be able to contribute.

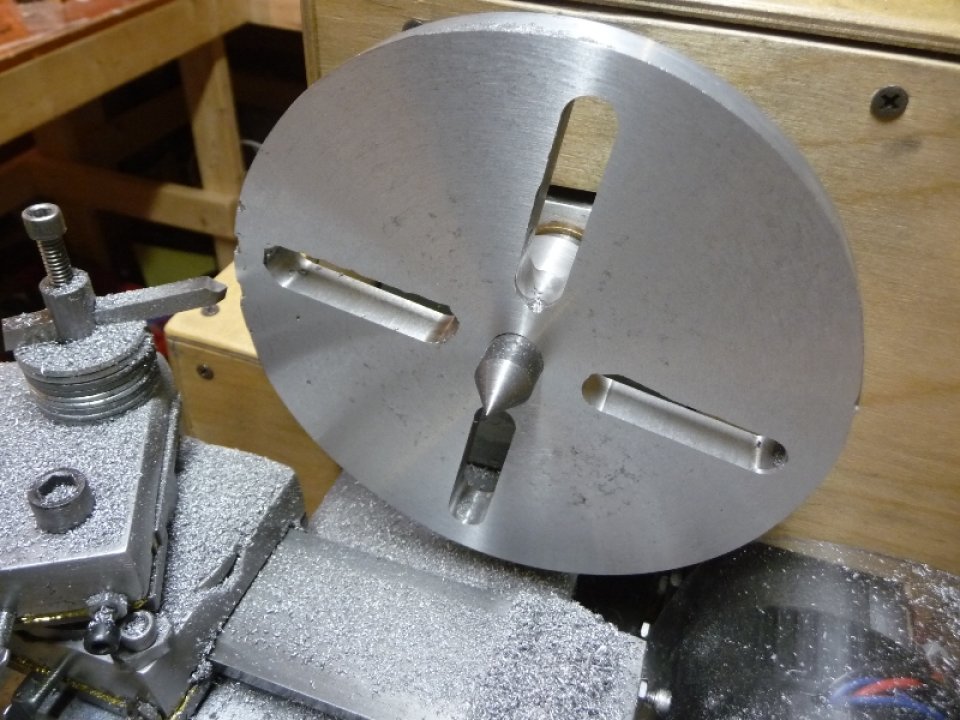

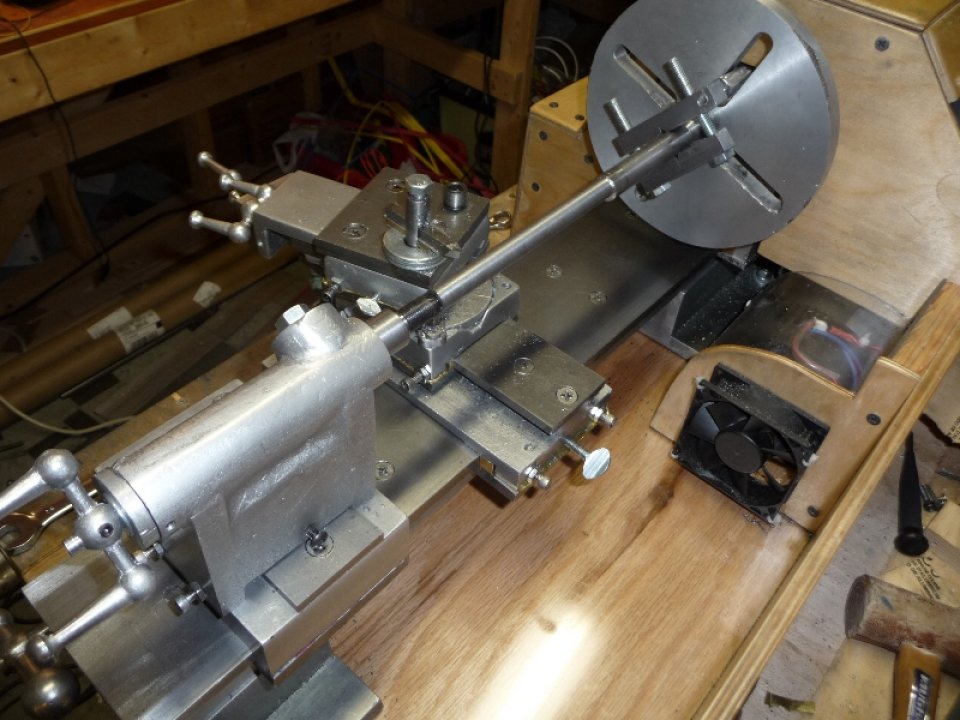

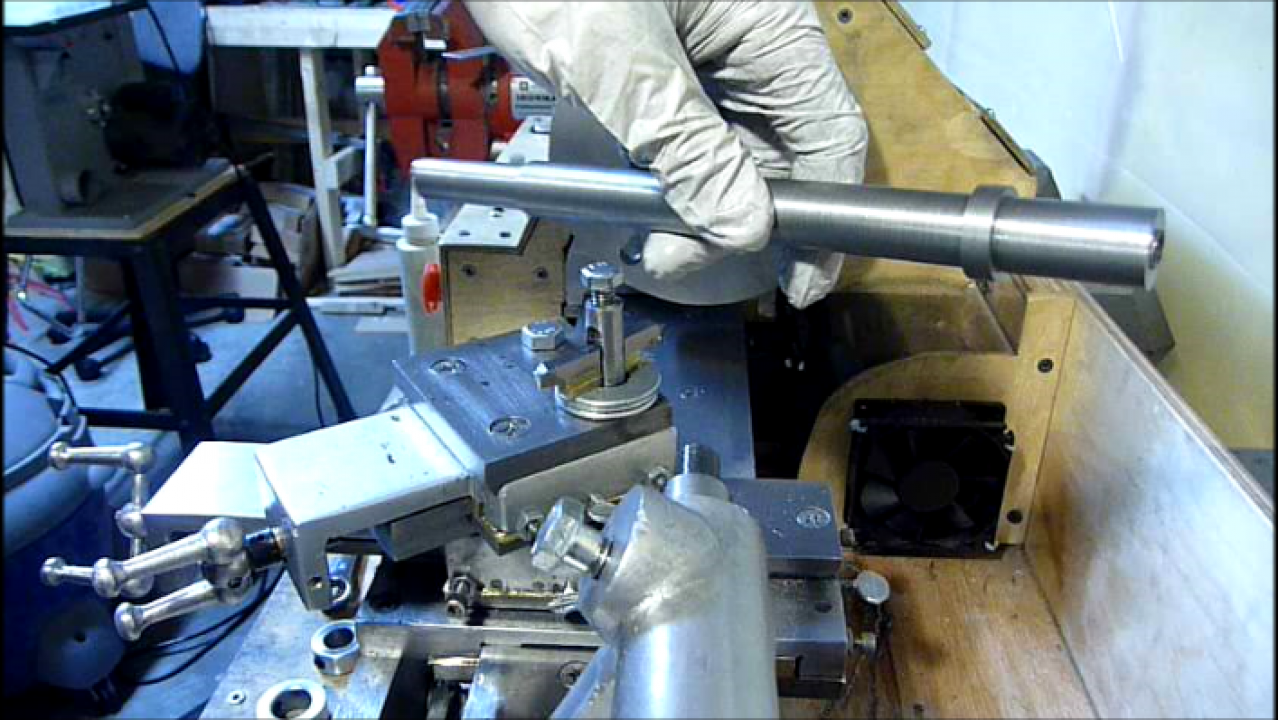

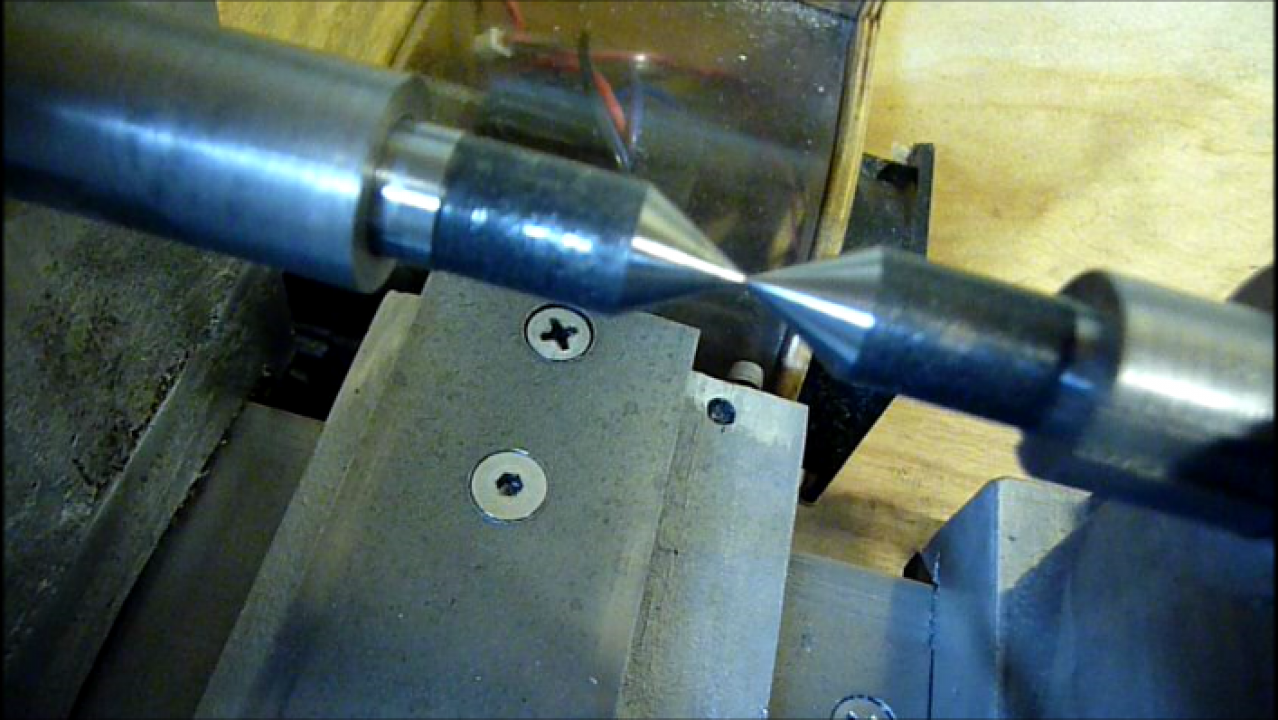

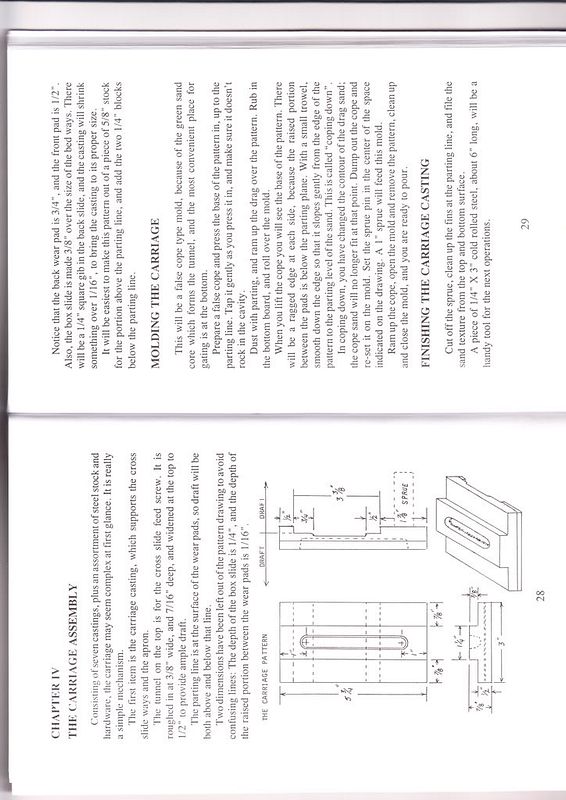

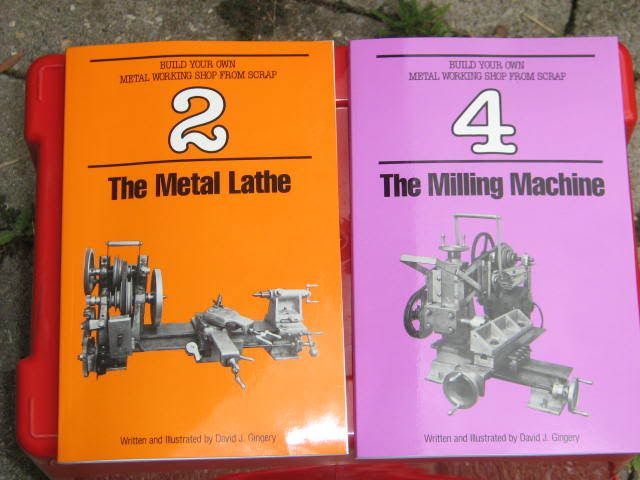

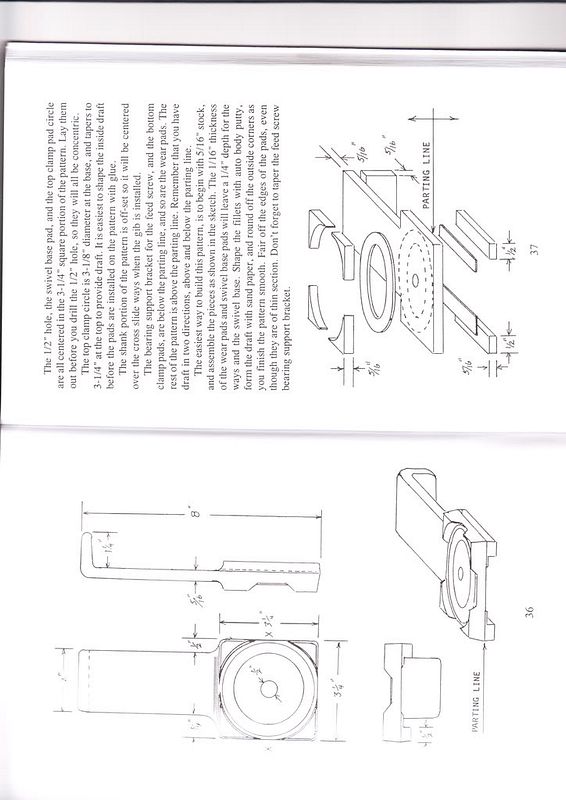

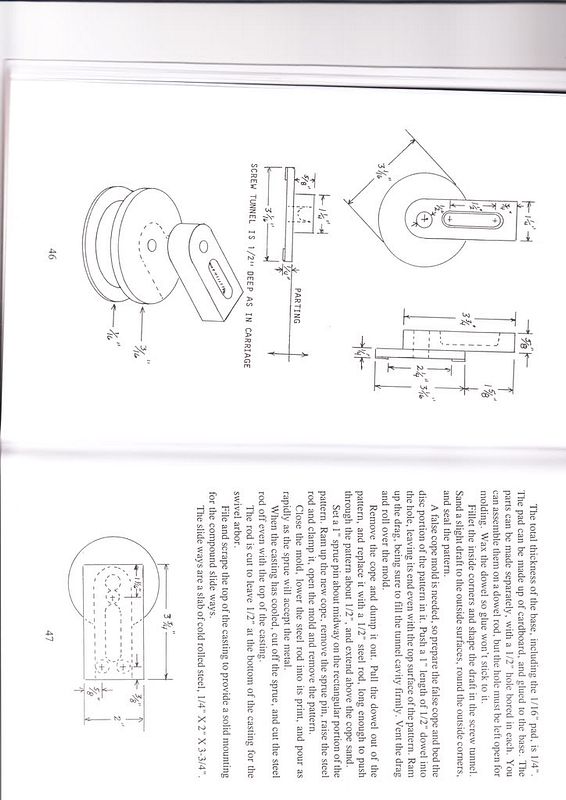

this is my casting project. i was waiting till i had all my castings finished and was going to post in the "working with castings" section covering the assembly of the lathe. this is a work in progress but here is my progress to date.

im now up to the headstock and i needed to get a bigger pot which ive now done. pending a successful casting of the headstock i will then frabricate the bed and start assembly

this is my casting project. i was waiting till i had all my castings finished and was going to post in the "working with castings" section covering the assembly of the lathe. this is a work in progress but here is my progress to date.

im now up to the headstock and i needed to get a bigger pot which ive now done. pending a successful casting of the headstock i will then frabricate the bed and start assembly