Kaleb

Senior Member

- Joined

- Jan 3, 2010

- Messages

- 272

- Reaction score

- 27

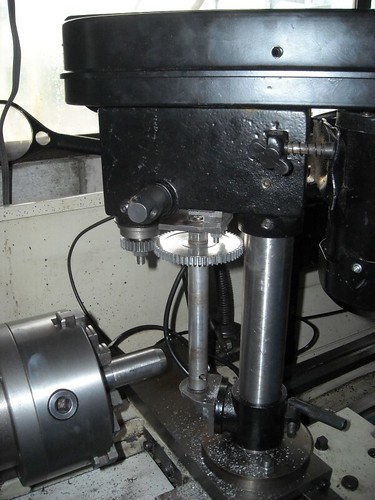

I've heard that you can cut gears on a lathe with some fancy setups. Does anyone here do it? If so, I'd like some hints for the fixtures or plans, particularly if you use it on a 9" South Bend or a copy thereof, since I am running a 9" Hercus, which is almost identical to a South Bend.