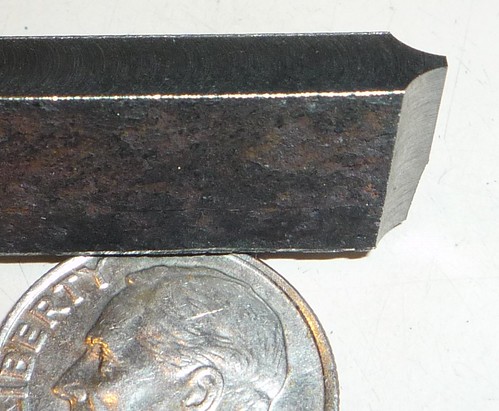

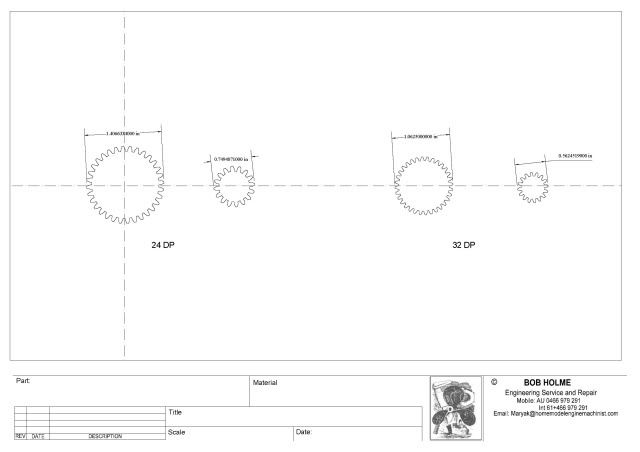

Mosey---I did make a single point gear cutter myself, as shown in the picture, and I did cut two gears which mesh well. I ground the tooth profile of the cutter from 01 steel to match an existing gear that I already had and flame hardened it . Although it worked, I was not terribly happy with the shape of the gear teeth, and I found that the single point contacting my aluminum blanks seemed to place a lot of impact stress on my small mill. It is definitly possible to do this. Captain Jerry did the same thing at about the same time and was very pleased with his results. I have been fortunate to find a very lucrative design project this fall which has given me some unexpected cash, so I thought I would treat myself to a set of gear cutters and some 1-2-3 blocks.