rythmnbls

Well-Known Member

- Joined

- Jan 14, 2012

- Messages

- 115

- Reaction score

- 31

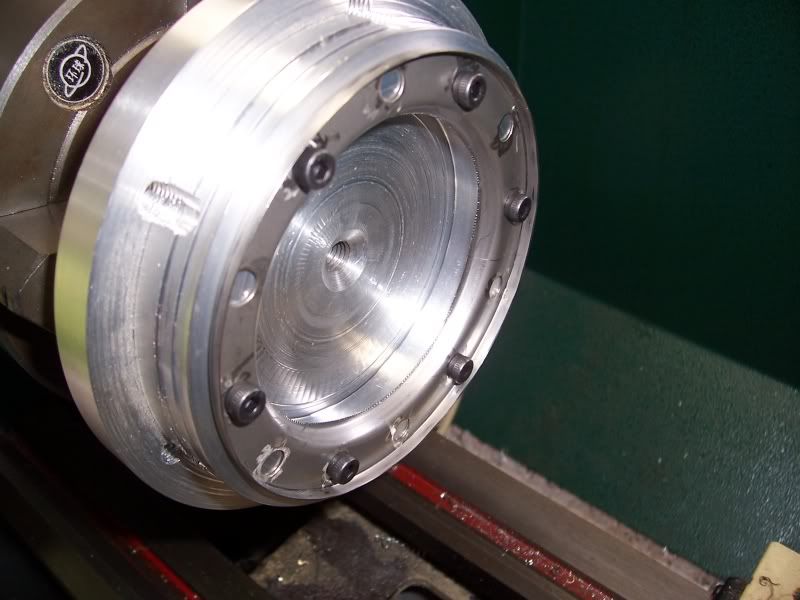

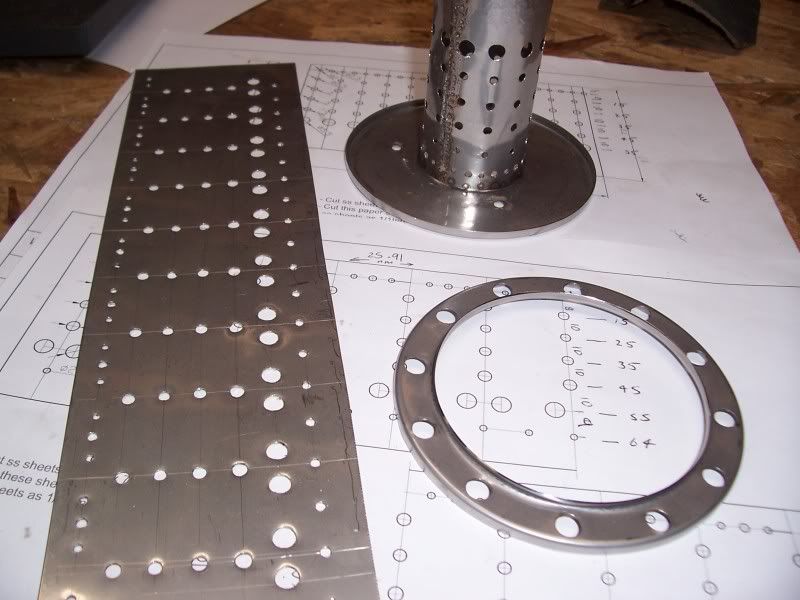

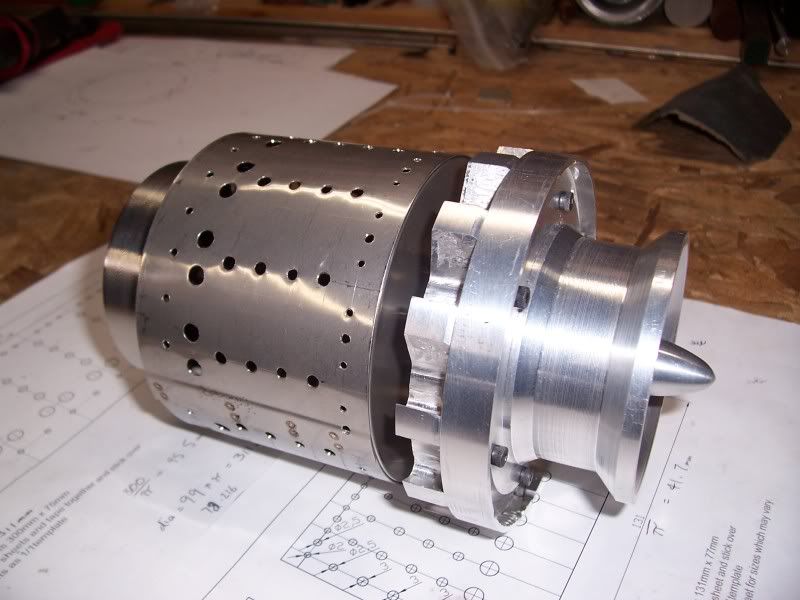

I thought the membership here might be interested in a pictorial build log of my current gas turbine project. The turbine is a 180N/40lbs thrust design by Gerald Rutten. Plans can be downloaded here http://members.tele2.nl/geraldensuzanne/turbines.htm .

The engine presented here has some changes from the original design, the turbine wheel is larger, 75mm instead of 70mm, and the compressor wheel is a Garrett TO4E-54 instead of the Schwitzer 316954.

Here is the link to the album on photobucket http://s87.photobucket.com/albums/k142/madluther/Turbine 2/

Slideshow of the above http://s87.photobucket.com/albums/k142/madluther/Turbine 2/?albumview=slideshow

Thanks for reading.

Steve.

The engine presented here has some changes from the original design, the turbine wheel is larger, 75mm instead of 70mm, and the compressor wheel is a Garrett TO4E-54 instead of the Schwitzer 316954.

Here is the link to the album on photobucket http://s87.photobucket.com/albums/k142/madluther/Turbine 2/

Slideshow of the above http://s87.photobucket.com/albums/k142/madluther/Turbine 2/?albumview=slideshow

Thanks for reading.

Steve.