SOLD 7/18/2010

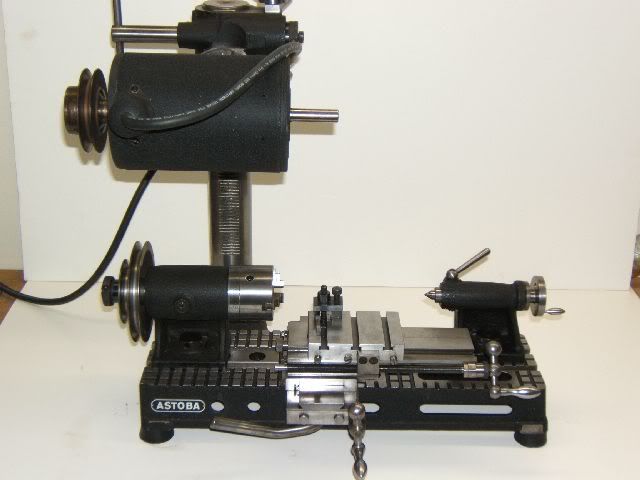

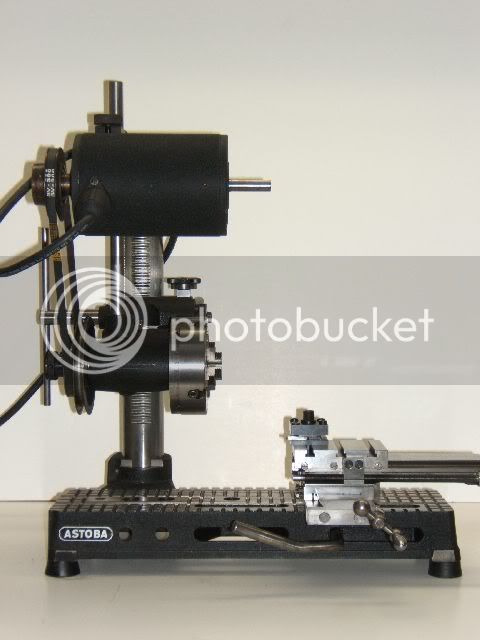

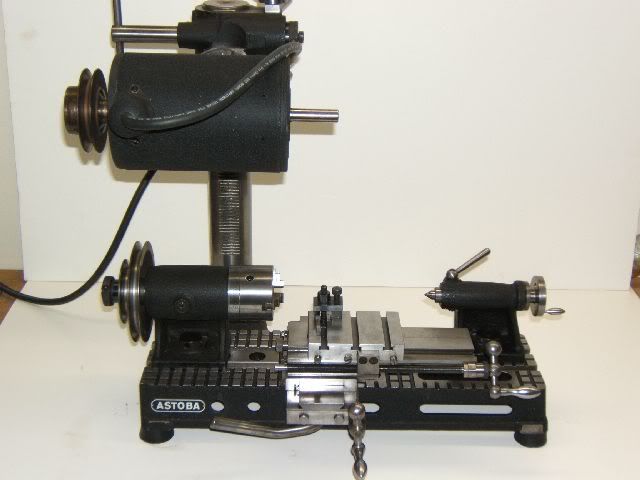

I've moved on to some larger dedicated free-standing machines so it's time to sell my Astoba benchtop universal mill & lathe, made in Switerland. I'd like $3,500. Here is some info from Tony's site (in fact, my machine is pictured there): http://www.lathes.co.uk/meyerburger/page3.html

It is substantially indentical to the Hommel machine, though the Hommel was made in Germany and I'm not sure which preceeded the other. Here's another link from Tony's site: http://www.lathes.co.uk/hommel/

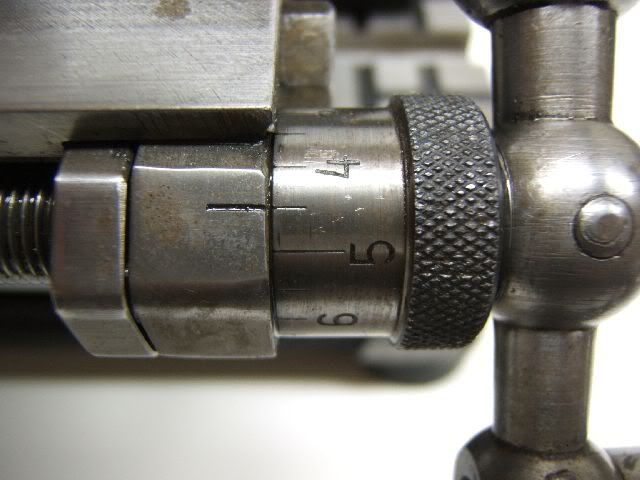

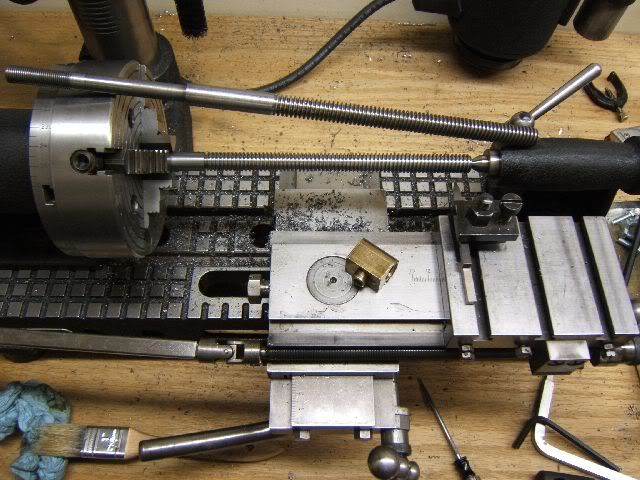

My machine is well tooled. It comes with an indexing rotary table, both metric and english collet sets, metric and english thread cutting plates (and all the necessary gears), milling table, attachment for power longitudinal feed, graver t-rest, rear mount cutoff tool holder, boring bars, milling vise, fly cutters, three jaw chuck, four jaw chuck, two drill chucks (one on a spindle arbor, one on a tailstock arbor), steady rest, draw bar collet work stops, face plates (x3), grinding table, grinding wheel, lathe dogs, knurling cutters and bars, slotting cutters and bars, hold down clamps, 4-position cutting tool holders (x2), end mills, and

[WHEW ...]

the head stock bearing pin spanner, horizontal mill headstock arbors (x2), headstock drill, extra chuck arbors (x2, in addition to one already mounted to a chuck), tailstock drill chuck arbor (one, in addition to the one already mounted to a chuck), tailstock dead centers (x4, two long two short), tailstock V-arbor, tailstock flat plates (x3, Ive used these to start a die straight), headstock centers for metal (x2), headstock centers for wood (x2, they have pointed center pin and two sharpened dogs).

Bob Farr

(313) 673-6679 cell

[email protected] or PM me here

Pics of my machine:

I've moved on to some larger dedicated free-standing machines so it's time to sell my Astoba benchtop universal mill & lathe, made in Switerland. I'd like $3,500. Here is some info from Tony's site (in fact, my machine is pictured there): http://www.lathes.co.uk/meyerburger/page3.html

It is substantially indentical to the Hommel machine, though the Hommel was made in Germany and I'm not sure which preceeded the other. Here's another link from Tony's site: http://www.lathes.co.uk/hommel/

My machine is well tooled. It comes with an indexing rotary table, both metric and english collet sets, metric and english thread cutting plates (and all the necessary gears), milling table, attachment for power longitudinal feed, graver t-rest, rear mount cutoff tool holder, boring bars, milling vise, fly cutters, three jaw chuck, four jaw chuck, two drill chucks (one on a spindle arbor, one on a tailstock arbor), steady rest, draw bar collet work stops, face plates (x3), grinding table, grinding wheel, lathe dogs, knurling cutters and bars, slotting cutters and bars, hold down clamps, 4-position cutting tool holders (x2), end mills, and

[WHEW ...]

the head stock bearing pin spanner, horizontal mill headstock arbors (x2), headstock drill, extra chuck arbors (x2, in addition to one already mounted to a chuck), tailstock drill chuck arbor (one, in addition to the one already mounted to a chuck), tailstock dead centers (x4, two long two short), tailstock V-arbor, tailstock flat plates (x3, Ive used these to start a die straight), headstock centers for metal (x2), headstock centers for wood (x2, they have pointed center pin and two sharpened dogs).

Bob Farr

(313) 673-6679 cell

[email protected] or PM me here

Pics of my machine: