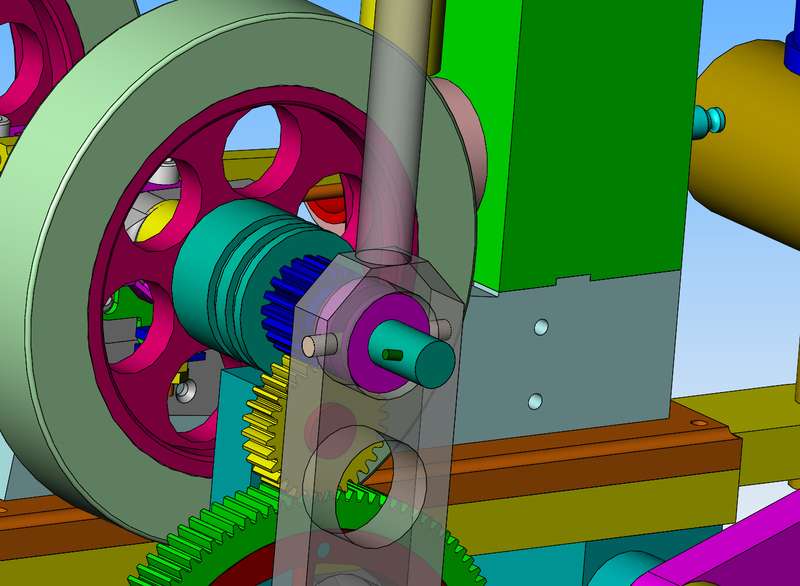

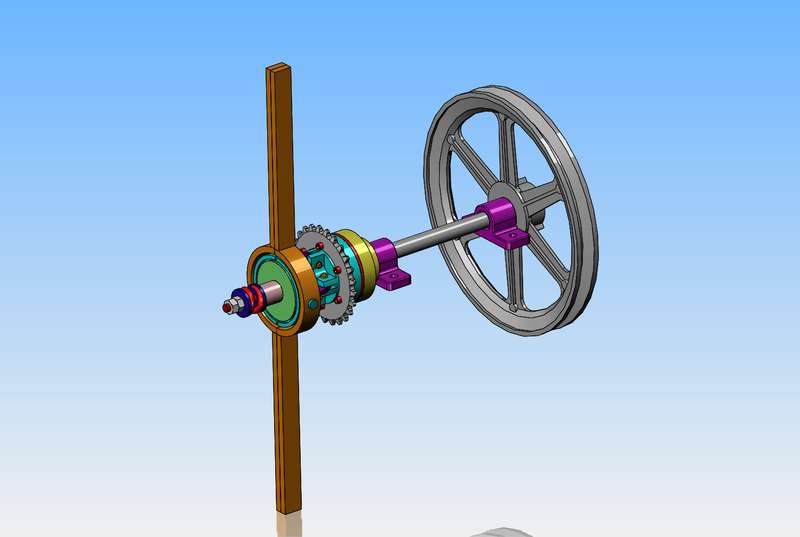

So--If I had my friction material, we're ready to rock and roll. Since there is no way to show inanimate pictures and tell people "it works", I will be rigging a drive and a clutch handle and setting up a live performance I can take a video of.

centrifugal clutch requires a sharp increase of speed, Brian's engine runs very close to the same speed even under a loadYou should try making a centrifugal clutch, or buy a rc one.

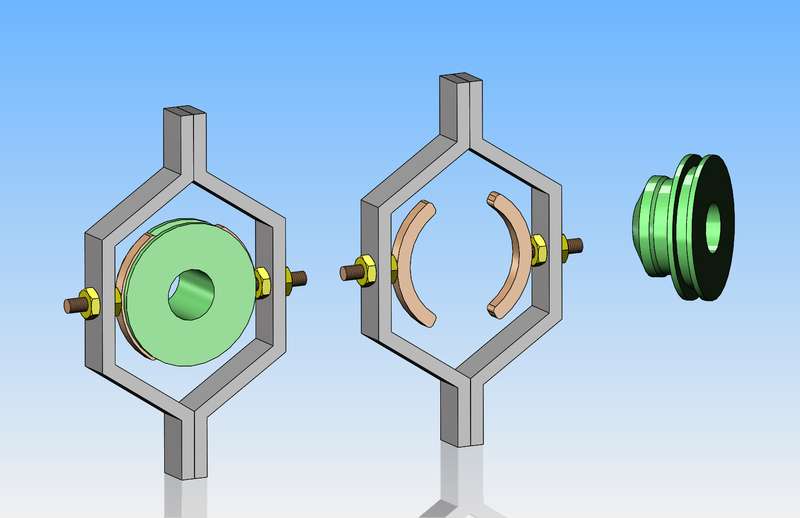

I can get very close to what was originally designed by cutting the blue inserts from bronze, soldering on stub shafts, and using a piece of 2 1/2" std. pipe to form the outer housing. Not really sure that I want t go to all that bother, but maybe. A lot depends on how well I can silver solder onto bronze.

Brian, reading this thread is interesting because you understand, just by looking at a machine, how the parts function to handle the forces they experience. They developed that way because other solutions had broken, wore out etc. Its interesting to think about the 'evolution' of such things (at least for me

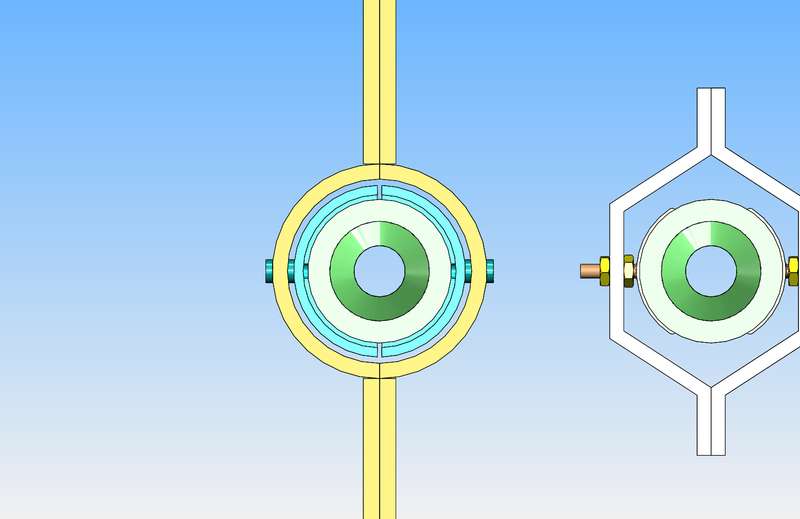

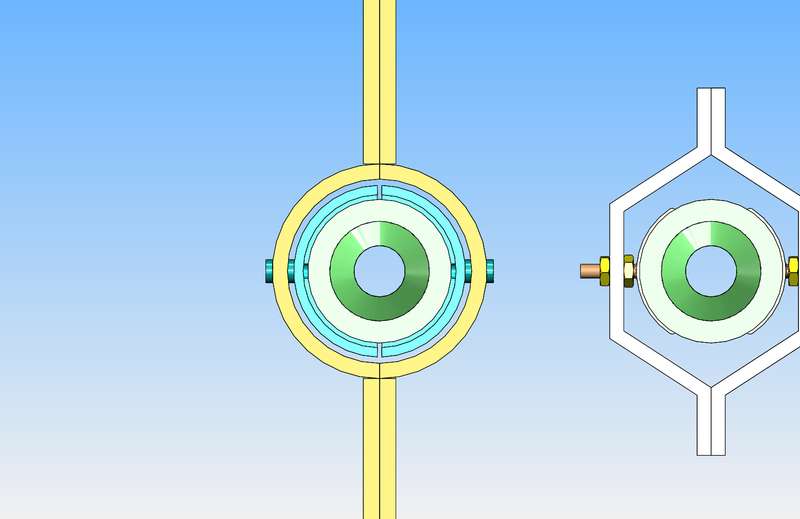

You discovered a subtlety in an original design (the brass half rings). I assume they function as a kind of split bushing, to 'cradle' the 'drum' and spread the load of pulling it along the shaft. Actually its kind of gimbal. I *guess* you could also imagine it as an uncut ring, like timbale, it you had some way of holding it on the drum - but that would take a collar, or similar.

I'm just kicking around different daring solutions here. Because its fun to think about

Brian: I have been following this thread with interest. When I was on the farm, we had a Wisconsin single lung engine with an enclosed clutch assembly and an exterior lever to engage or disengage the clutch. the lever acted as a snap over center motion and the clutch itself was a cone clutch with a l ining. I know you have done a lot of work on your current assembly but it could be the cone clutch complex is a better alternative. John

Brian,toolingjim--McMaster won't sell/ship to Canada unless you had an account with them 10 years ago. A gentleman in British Columbia has a piece of the McMaster Carr stuff, and is sending me enough to make this clutch.---Brian

Enter your email address to join: