- Joined

- Oct 1, 2010

- Messages

- 1,340

- Reaction score

- 393

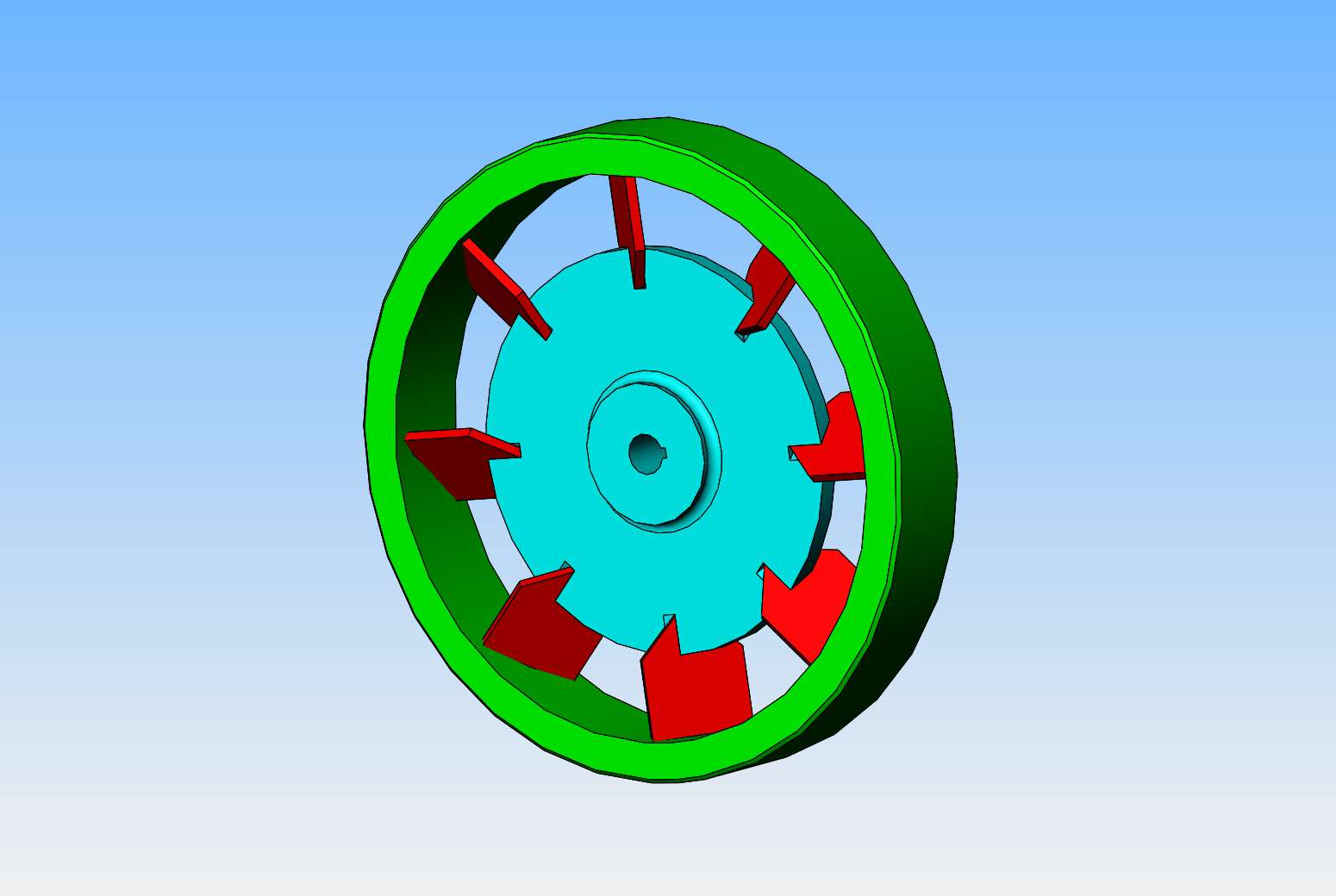

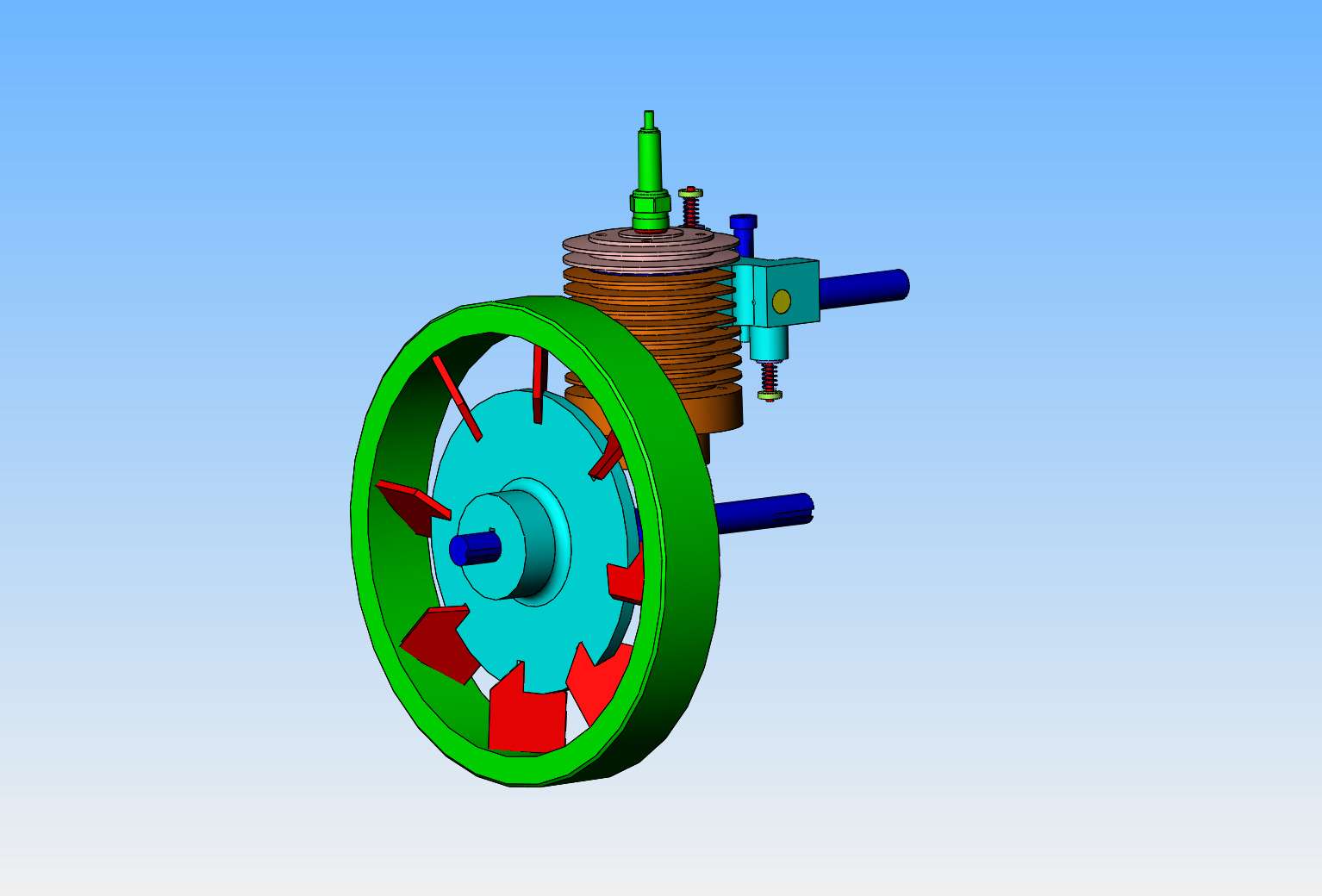

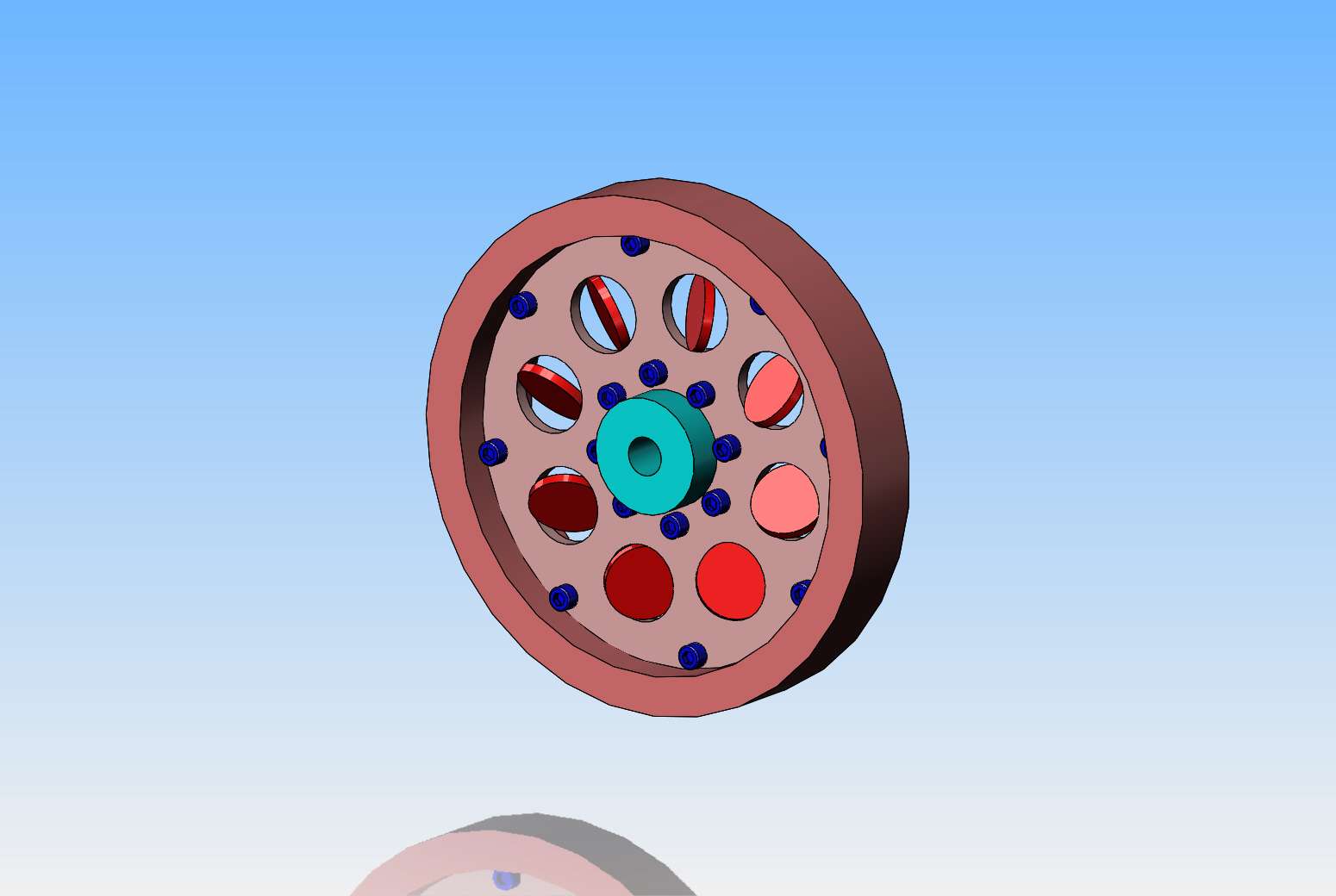

Your "what it should be" description started me thinking about the Maytag engines, in the way they look. The flywheel they used had vanes. Most of us know the single-cylinder Maytag, but they also made some with 2 cylinders. I think they were 2-cycle, but I'm talking about how they looked. Searching the net will show lots of examples.

--ShopShoe

--ShopShoe