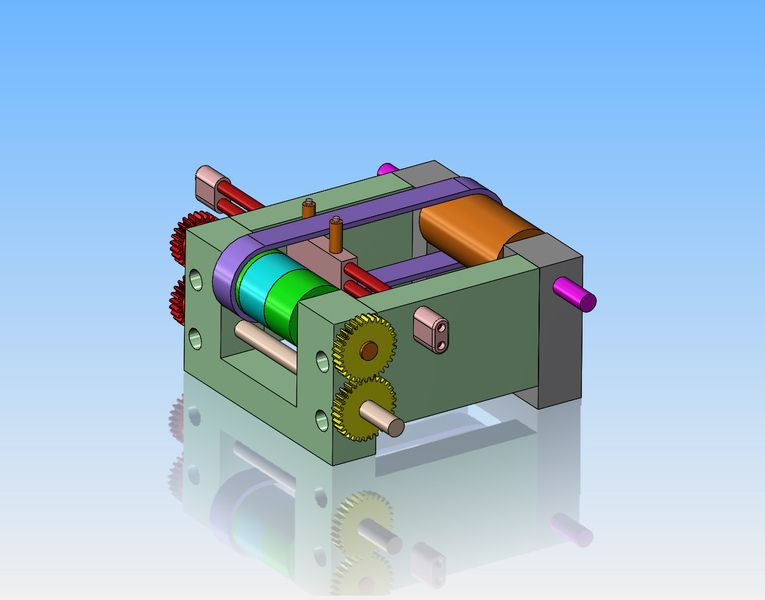

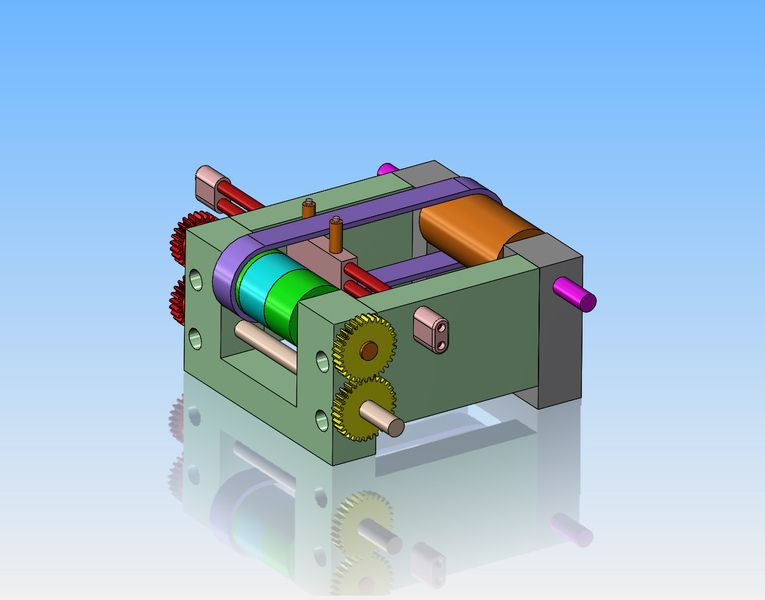

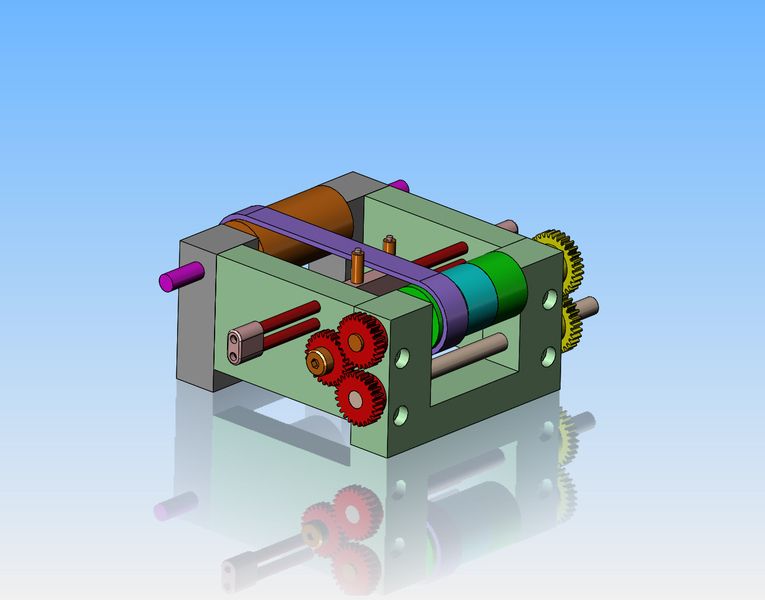

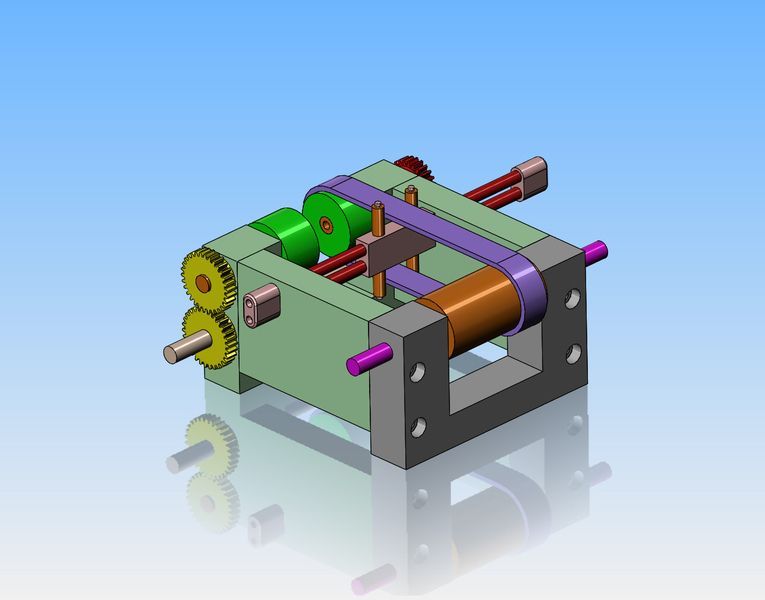

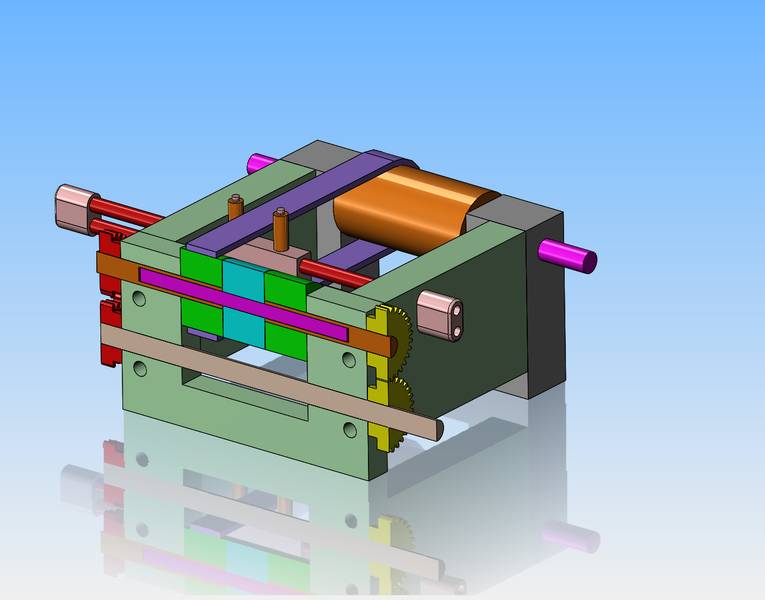

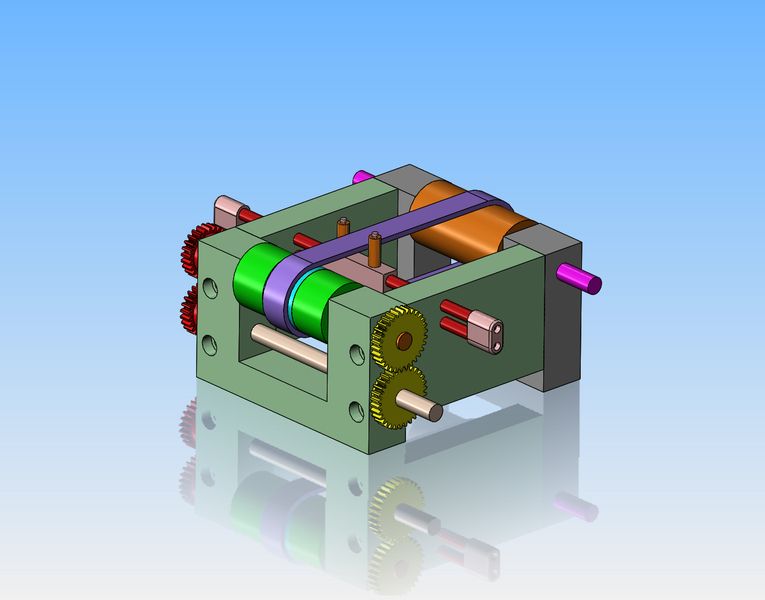

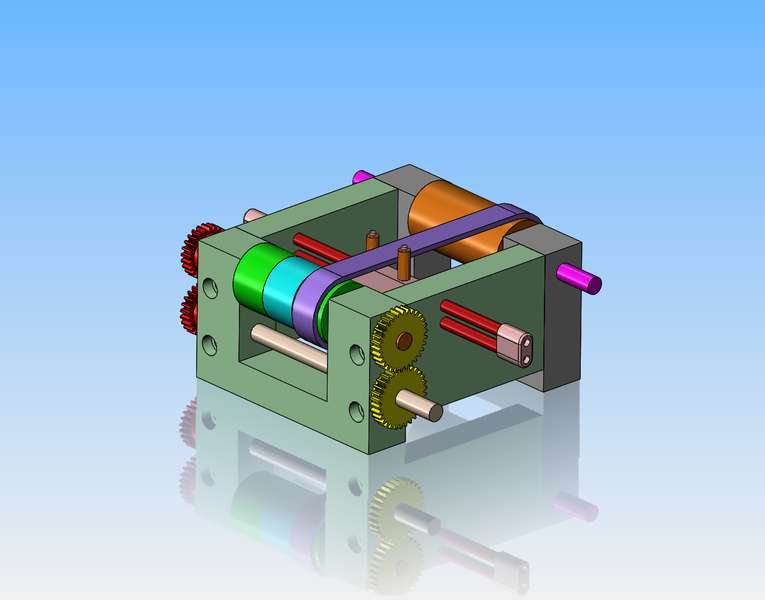

With the end of every project, I declare that I've had enough machining, and I'm going to take a break for a couple of months. Then I lay in bed at night, and it isn't sugar plum fairies that dance thru my head---it's machinery!! One of the things that fascinates me is how they shifted flat belts pulleys into reverse on the old lineshaft machinery. I've seen pictures of it but never have seen it done in "real life". I just happen to have a small flat belt, about 5/8" wide x 0.100" thick that I scavenged from somewhere, and time on my hands. So--I spent this morning modelling a flat belt reversing mechanism. In the attached picture, the power is input to the beige colored counter-shaft in the lower left hand corner. This will make the gear which meshes with it rotate in the opposite direction and carry the green pulley closest to that gear and the shaft it rides on with it. However, the belt is at the other green pulley on the far side from the yellow gear, so what's going on here?