Hi everybody

I started on a flame eater I am building ,This project started when i found a nice piece of stainless hex

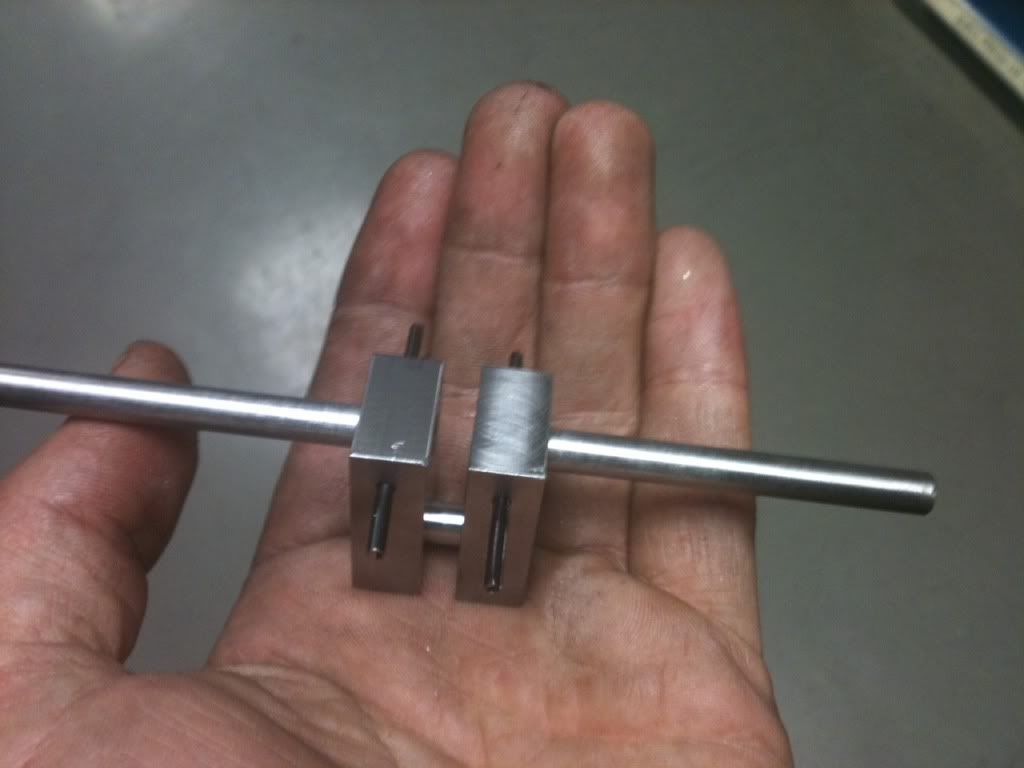

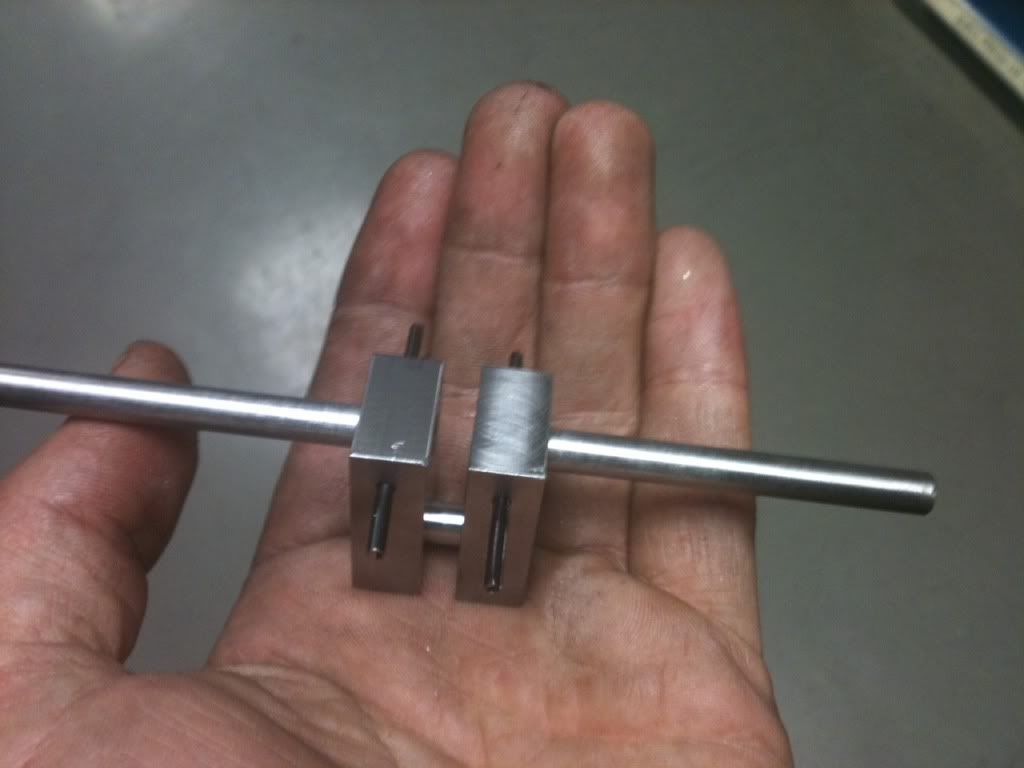

which I wanted to mount at 45 degrees to look some way like a cannon......I am using a CI piston 26mm with a 40 mm total stroke ,The crankshaft is built up,

I will silver solder this later just pressed together for the moment, and my flywheels need spokes or holes to lighten,

I will silver solder this later just pressed together for the moment, and my flywheels need spokes or holes to lighten,

I have not figured out where or what type of valve to use yet, I am slowly running out of space but I will figure it out. Any ideas would be great.

Regards Jamie

I started on a flame eater I am building ,This project started when i found a nice piece of stainless hex

which I wanted to mount at 45 degrees to look some way like a cannon......I am using a CI piston 26mm with a 40 mm total stroke ,The crankshaft is built up,

I have not figured out where or what type of valve to use yet, I am slowly running out of space but I will figure it out. Any ideas would be great.

Regards Jamie