After my last project that took mounts to complete I wanted something that could be completed quickly. I also wanted a project that used material and tooling on hand.

After looking around I selected Elmer's Tiny Engine. I made some minor adaptations to use material I had. I changed the 1/16" rods to 0.084 drill rods that I had from the previous beam engine project. I only needed to get some music wire from the hobby store. With the 0.085 rod I decided to use a 2-26 nut to compress the spring.

Since this was a fast project with relative straight forward machine I did not do a build log. The first two photos show the parts I fabricated. I wanted the spring pitch to be approximately twice the wire diameter so I simply wound two wires side by side on the mandrel and separated them after winding. It turned out to be quick and easy with the .015" wire.

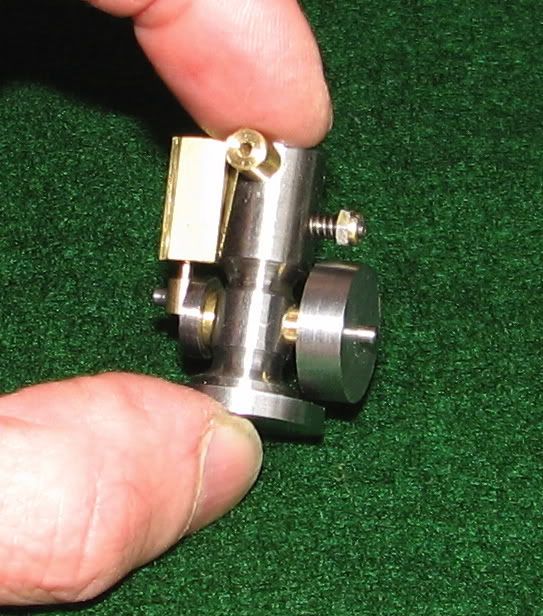

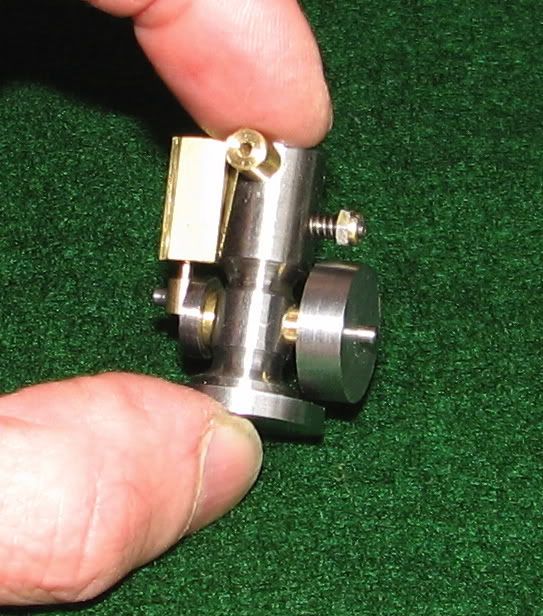

The next two photos show the assembled engine. The closeups show all the dirt and dust that I should have cleaned off. When I first assembled the pivot to the cylinder using Loctite I did not get the pivot perpendicular to the cylinder face. I heated the part to break the Loctite bond and I made a simple fixture and to hold the parts. The second attempt worked much better.

I also had some interference between the piston and the cylinder at top dead center. I must not have drilled and reamed the cylinder quite deep enough. Shortening the piston by 0.008" fixed that problem. Here is a video of the engine in operation.

[ame]http://www.youtube.com/watch?v=yYyLfPNbN9E[/ame]

Overall I am pleased with this little "quicky" project

Thanks for checking in

Eric

After looking around I selected Elmer's Tiny Engine. I made some minor adaptations to use material I had. I changed the 1/16" rods to 0.084 drill rods that I had from the previous beam engine project. I only needed to get some music wire from the hobby store. With the 0.085 rod I decided to use a 2-26 nut to compress the spring.

Since this was a fast project with relative straight forward machine I did not do a build log. The first two photos show the parts I fabricated. I wanted the spring pitch to be approximately twice the wire diameter so I simply wound two wires side by side on the mandrel and separated them after winding. It turned out to be quick and easy with the .015" wire.

The next two photos show the assembled engine. The closeups show all the dirt and dust that I should have cleaned off. When I first assembled the pivot to the cylinder using Loctite I did not get the pivot perpendicular to the cylinder face. I heated the part to break the Loctite bond and I made a simple fixture and to hold the parts. The second attempt worked much better.

I also had some interference between the piston and the cylinder at top dead center. I must not have drilled and reamed the cylinder quite deep enough. Shortening the piston by 0.008" fixed that problem. Here is a video of the engine in operation.

[ame]http://www.youtube.com/watch?v=yYyLfPNbN9E[/ame]

Overall I am pleased with this little "quicky" project

Thanks for checking in

Eric