- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

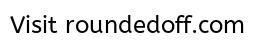

A ex work friend bought himself a 3D printer and asked me if I had anything that would be suitable that he could use that showed the off the printers capability to produce molding paterns, well i didn't so I contacted Rob Willson and he kindly provided a 3D drawing of a cylinder patern.

This is the result

Aparently the printer is not unlike a CNC router but instead of a cutter it has a plastic injecting nozle, you first have to convert the 3D drawing into G code as used for CNC, this is used to drive the printer that builds up a matrix of plastic to form the patern.

Neat hey :big:

Stew

This is the result

Aparently the printer is not unlike a CNC router but instead of a cutter it has a plastic injecting nozle, you first have to convert the 3D drawing into G code as used for CNC, this is used to drive the printer that builds up a matrix of plastic to form the patern.

Neat hey :big:

Stew