Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

Every month we see great projects being posted and wanted to bring special attention to engines that stand out. They might be someones first effort or one made buy an old timer that has been at this for while. They might be made from barstock, castings, or just stuff they dug out of the scrap bin. We dont discriminate around here, we like them all. This is intended to make the site more fun. Hopefully everyone that has an engine that they built, will be encouraged to post pictures of it.

All the bugs arent worked out yet. What we are planning to do is. The moderators will chose 3 models every month. Then there will be a poll that the members will vote on to choose the winner. There are no prizes, just that warm fuzzy feeling near your heart )

)

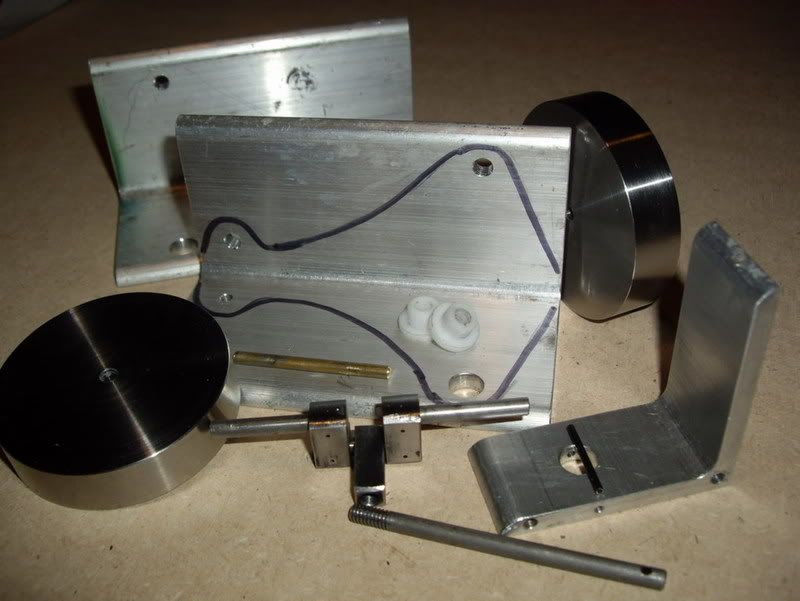

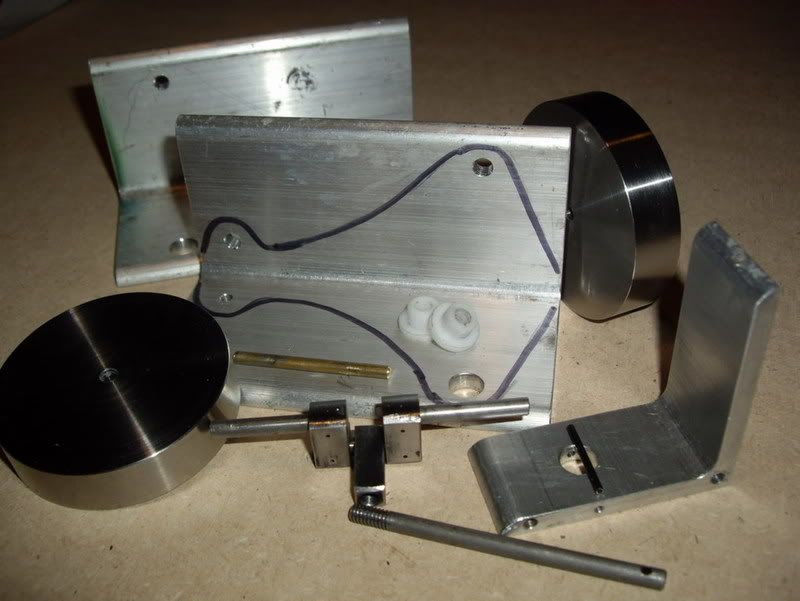

For the first Engine of the month, I want to bring special attention to Davyboys Treadle Engine. He started out with an idea and some scraps. He took them and turned them into a functional piece of art. If you dont believe me, watch his Video. Not many people can do that and he should be proud.

Here are the two links to his build One, Two.

Way to Go Davyboy!!!

All the bugs arent worked out yet. What we are planning to do is. The moderators will chose 3 models every month. Then there will be a poll that the members will vote on to choose the winner. There are no prizes, just that warm fuzzy feeling near your heart

For the first Engine of the month, I want to bring special attention to Davyboys Treadle Engine. He started out with an idea and some scraps. He took them and turned them into a functional piece of art. If you dont believe me, watch his Video. Not many people can do that and he should be proud.

Here are the two links to his build One, Two.

Way to Go Davyboy!!!