You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Emcoturn 120P

- Thread starter rcfreak177

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

DICKEYBIRD

Well-Known Member

- Joined

- Sep 27, 2007

- Messages

- 653

- Reaction score

- 45

My sentiments exactly!Swede said:Is it there yet? Is it there yet?;D

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

Yep Sure is,

I picked up my new toy on Friday and now have it at home. I will put up some photo's soon.

The overall condition is actually better than expected. Funny thing I disconnected the air supply to the tail stock and there was still air pressure there, Gave me a fright.

There may be a card missing from the controller, It shows it on the drawing inside the rear cover of the box but I cant seem to find it on any of the schematics.

The card is called the clamping device card F1Z 333 000, F1Z 431 000.

I also have all the original manuals with the machine, But no MSD tape.

I picked up my new toy on Friday and now have it at home. I will put up some photo's soon.

The overall condition is actually better than expected. Funny thing I disconnected the air supply to the tail stock and there was still air pressure there, Gave me a fright.

There may be a card missing from the controller, It shows it on the drawing inside the rear cover of the box but I cant seem to find it on any of the schematics.

The card is called the clamping device card F1Z 333 000, F1Z 431 000.

I also have all the original manuals with the machine, But no MSD tape.

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

Alright,

Still no photo's, I have powered up the machine and much to my surprise "IT WORKS" The collet chuck works, The tail stock works The MSD is sill in the control

(now I have to figure how to retrieve it for the future) all the axis move as they should.

I am stoked. There is one drama, I get an error 50 Turret hardware failure when I try to index to the next tool. I have tracked this down to the locking pin on the back of the tool plate is seized, Not a big issue just a matter of pulling the unit apart and cleaning it up. I did some research and found that the board I previously thought was missing is actually for a milling machine. These controllers were used on lathes and mills. there was an upgrade for the mill which was a programmable vice which is what the boars controls.

Baz.

Still no photo's, I have powered up the machine and much to my surprise "IT WORKS" The collet chuck works, The tail stock works The MSD is sill in the control

(now I have to figure how to retrieve it for the future) all the axis move as they should.

I am stoked. There is one drama, I get an error 50 Turret hardware failure when I try to index to the next tool. I have tracked this down to the locking pin on the back of the tool plate is seized, Not a big issue just a matter of pulling the unit apart and cleaning it up. I did some research and found that the board I previously thought was missing is actually for a milling machine. These controllers were used on lathes and mills. there was an upgrade for the mill which was a programmable vice which is what the boars controls.

Baz.

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

Hi Greg,

I used a step down transformer, It takes 415V three phase to 380V.

I turned the machine in this morning and one of the resistors fried on the z axis drive.

I should be able to fix this though/

If anybody out there has boards of any sort or parts for the Emcotronic T1 or T02 controller Mill or Lathe, working or not I will be willing to purchase them. I would love to be able to have spares readily available.

I know this sounds silly as retrofitting this machine would be more reliable but I somehow like the feeling of having a piece of history. I believe that Emco and the technology they had in 1987 was way ahead if its time.

Cheers Baz.

I used a step down transformer, It takes 415V three phase to 380V.

I turned the machine in this morning and one of the resistors fried on the z axis drive.

I should be able to fix this though/

If anybody out there has boards of any sort or parts for the Emcotronic T1 or T02 controller Mill or Lathe, working or not I will be willing to purchase them. I would love to be able to have spares readily available.

I know this sounds silly as retrofitting this machine would be more reliable but I somehow like the feeling of having a piece of history. I believe that Emco and the technology they had in 1987 was way ahead if its time.

Cheers Baz.

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

WOW!

I logged an enquiry with Emco too see if they still had stock of these boards in question.

I did get a prompt reply from a specialist.

Dear Sir,

You have the option to send the boards to Emco, We will repair them and test for 24 hours.

The cost will be as follows,

Repair stepper drive: 1625 Euro

repair turret drive board: 790 Euro

Regards the Emco team ??? ??? ???

I can't believe the prices, Although I am sure that the quality of repair and service will be excellent.

I could have them reverse engineered in China for this sort of money. Then they would be readily available to everybody.

What an eye opener.

Cheers Baz.

I logged an enquiry with Emco too see if they still had stock of these boards in question.

I did get a prompt reply from a specialist.

Dear Sir,

You have the option to send the boards to Emco, We will repair them and test for 24 hours.

The cost will be as follows,

Repair stepper drive: 1625 Euro

repair turret drive board: 790 Euro

Regards the Emco team ??? ??? ???

I can't believe the prices, Although I am sure that the quality of repair and service will be excellent.

I could have them reverse engineered in China for this sort of money. Then they would be readily available to everybody.

What an eye opener.

Cheers Baz.

Yes, now you understand why these get put out to pasture when they fail in the machine shop, and why they get retrofitted in the home shop.

There is a guy on the Yahoo group that will repair axis boards for a reasonable price. I think he's on PM too.

There is a guy on the Yahoo group that will repair axis boards for a reasonable price. I think he's on PM too.

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

Hi Greg,

Thanks for the lead.

I have found the guy who will repair the boards. I think his name is Wrench on the Practical Machinist

forum.

I have managed to get my head around the circuit layout on the boards.

I guess I am lucky as I deal with very complex electronics at work as a product specialist repairing all the faults that our fitters can't work out on Atlas Copco Drill rigs.

These machines are running either PLC or can-bus systems and have found the majority of faults are electrical. With the Emco machines being designed in Austria and Atlas Copco being designed in Sweden they both have a very similar way of designing electronics. definitely a bit different to the Japanese.

I am a stubborn bugger and will persist until I get it right.

I also agree retrofit is the most sensible option though.

I am looking forward to you'r build on the Emco. The photo's that you uploaded were great, I can' believe how the machine cleaned up, Looks a million bucks.

I have also never seen one before as they are extremely rare in Australia.

Does you'r machine have the pneumatic tail stock and collet chuck?

And do you have any plans for the tool turret control as of yet?

Cheers Baz.

Thanks for the lead.

I have found the guy who will repair the boards. I think his name is Wrench on the Practical Machinist

forum.

I have managed to get my head around the circuit layout on the boards.

I guess I am lucky as I deal with very complex electronics at work as a product specialist repairing all the faults that our fitters can't work out on Atlas Copco Drill rigs.

These machines are running either PLC or can-bus systems and have found the majority of faults are electrical. With the Emco machines being designed in Austria and Atlas Copco being designed in Sweden they both have a very similar way of designing electronics. definitely a bit different to the Japanese.

I am a stubborn bugger and will persist until I get it right.

I also agree retrofit is the most sensible option though.

I am looking forward to you'r build on the Emco. The photo's that you uploaded were great, I can' believe how the machine cleaned up, Looks a million bucks.

I have also never seen one before as they are extremely rare in Australia.

Does you'r machine have the pneumatic tail stock and collet chuck?

And do you have any plans for the tool turret control as of yet?

Cheers Baz.

Check the Yahoo group as well, I'm not sure if that the same guy.

We'll I've been slacking on making room for it in my workshop. I have to rearrange virtually everything to make it fit the way I want. I do have a pneumatic tail stock, and a manual tail stock which I'll likely sell. I got the machine without any chucks at all. I did find a manual 5C quick chuck and I plan to buy a decent 3 jaw. It's just as well it doesn't have the pnuematic chuck as I don't be myself doing much intense production. I was at the NAMES show a couple weeks ago and met the guy I purchased my first lathe from. It just so happens that he recently converted an Emco PC55 lathe and wrote code for that turret which appeared to be exactly the same design as the C6/120. I hope to make a visit with him soon to see his shop. I have a paying project to finish in the next few days, so maybe soon I'll get back to the Emco.

Greg

We'll I've been slacking on making room for it in my workshop. I have to rearrange virtually everything to make it fit the way I want. I do have a pneumatic tail stock, and a manual tail stock which I'll likely sell. I got the machine without any chucks at all. I did find a manual 5C quick chuck and I plan to buy a decent 3 jaw. It's just as well it doesn't have the pnuematic chuck as I don't be myself doing much intense production. I was at the NAMES show a couple weeks ago and met the guy I purchased my first lathe from. It just so happens that he recently converted an Emco PC55 lathe and wrote code for that turret which appeared to be exactly the same design as the C6/120. I hope to make a visit with him soon to see his shop. I have a paying project to finish in the next few days, so maybe soon I'll get back to the Emco.

Greg

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

After much delay I have managed to get the tool turret on my 120P working.

turns out there was 2 blown photo interrupters on the turret board.

In diagnosing this I blew up the L298 driver chip on the motor controller board as well as one of the

IC chip sets.

Funny story this one as I was not sure which one of the chips was faulty so I replaced all of them,

I also used a push in socket on the board so if they fail again in the future all I have to do is pry off the old chips and then push in new ones, Also replaced all the diodes. (a couple of diodes had leakage)

After doing all this I still had a error 50. Turns out that previous to me getting this machine someone else had a go at repairing this fault. The turret motor wires were reversed and also the input wires for the position sensors all mixed up.

At the end of the day I fixed it (with around a week of trying) and it is now working.

I have checked all the other functions and everything is in working order.

So now I have so many electrical spares for this machine it should live for another 25 years (touch wood)

Wow what a learning curve

Here is a somewhat blurry picture of the components that I changed

Cheers Baz.

turns out there was 2 blown photo interrupters on the turret board.

In diagnosing this I blew up the L298 driver chip on the motor controller board as well as one of the

IC chip sets.

Funny story this one as I was not sure which one of the chips was faulty so I replaced all of them,

I also used a push in socket on the board so if they fail again in the future all I have to do is pry off the old chips and then push in new ones, Also replaced all the diodes. (a couple of diodes had leakage)

After doing all this I still had a error 50. Turns out that previous to me getting this machine someone else had a go at repairing this fault. The turret motor wires were reversed and also the input wires for the position sensors all mixed up.

At the end of the day I fixed it (with around a week of trying) and it is now working.

I have checked all the other functions and everything is in working order.

So now I have so many electrical spares for this machine it should live for another 25 years (touch wood)

Wow what a learning curve

Here is a somewhat blurry picture of the components that I changed

Cheers Baz.

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

Not much happening with the Emco and the models lately, I bought a new house and am in the middle of moving out. I just love moving "NOT" The household stuff is easy, My workshop is another story.

I will be building a new home for my toys soon. Was thinking along the lines of a workshop size of

8 metres wide x 9 metres long with a height of 2.7 metres to the gutters. Can't wait until it is all done and life is business as usual.

Cheers Baz.

I will be building a new home for my toys soon. Was thinking along the lines of a workshop size of

8 metres wide x 9 metres long with a height of 2.7 metres to the gutters. Can't wait until it is all done and life is business as usual.

Cheers Baz.

ShedBoy

Senior Member

- Joined

- May 13, 2011

- Messages

- 792

- Reaction score

- 34

Hi Baz, good to here from you. I did the house rebuild thing but went the whole hog and demolished the old one and started again. New shed was on the cards from the start and was the last thing to be done, but it was worth it in the end. Worst thing I found with moving shed is now it takes me along time to find things, I am always changing the layout to make it better which compounds the first problem. One thing I did put in my shed that I am finding extremely handy is a large sink with water supply. Moving machines is never a fun job. Have fun and keep us informed.

Brock

Brock

leevalleycustoms

New Member

- Joined

- Mar 9, 2012

- Messages

- 3

- Reaction score

- 0

Hi

I've purchased a emcoturn 120 cnc lathe and it's 3 phase, I only have single phase in my unit. I purchased a 3 phase 6.3 kva 415v diesel generator hoping this would be sufficient, but the text on the screen was bouncing around and then it disappered. I'm really in need of some help to get this lathe running, I'm not to clued up on what I need. So can someone help me out and send a list of what I may need to purchase otherwise I will need to get an engineer out and they charge a fortune. Please help

I've purchased a emcoturn 120 cnc lathe and it's 3 phase, I only have single phase in my unit. I purchased a 3 phase 6.3 kva 415v diesel generator hoping this would be sufficient, but the text on the screen was bouncing around and then it disappered. I'm really in need of some help to get this lathe running, I'm not to clued up on what I need. So can someone help me out and send a list of what I may need to purchase otherwise I will need to get an engineer out and they charge a fortune. Please help

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

The logic side of the 120 works off single phase. Running the machine off a generator is not a good idea as the voltage is not stable enough. Also the power supply needs to be 380v on the 3 phase side.

I powered my machine via 240v single phase in order to test the logic and was able to move the axis's test the collet chuck and

tail stock, screen etc.

It is hard to say what you need, You may have a fault in the CRT monitor card. You will need the electrical schematics and also a solid background in electronics.

I would be very careful poking and prodding if you do not have the Electrical knowledge.

As we all know Electric shocks can Kill.

Cheers Baz.

I powered my machine via 240v single phase in order to test the logic and was able to move the axis's test the collet chuck and

tail stock, screen etc.

It is hard to say what you need, You may have a fault in the CRT monitor card. You will need the electrical schematics and also a solid background in electronics.

I would be very careful poking and prodding if you do not have the Electrical knowledge.

As we all know Electric shocks can Kill.

Cheers Baz.

leevalleycustoms

New Member

- Joined

- Mar 9, 2012

- Messages

- 3

- Reaction score

- 0

I'm thinking of selling my Emcot lathe 120, I can't seem to find out what I require to power up machine as I only have single phase. Anyone interested please reply.

petesurrey

New Member

- Joined

- Sep 17, 2012

- Messages

- 1

- Reaction score

- 0

I am interested in your emco please message me

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

It has been a while since I posted to this thread

Soooo

this is where I am at.

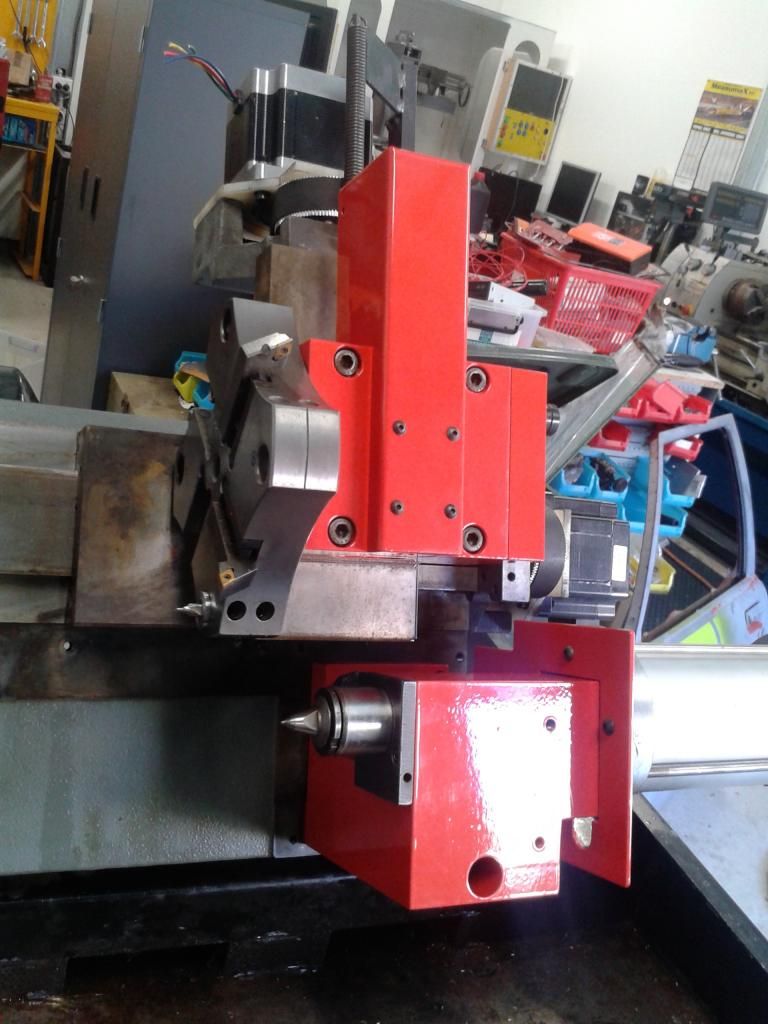

The Emco 120P lathe has had a birthday,

* Spindle rebuilt

* Auto tool turret rebuilt

* Auto Tail-stock rebuilt

* Chuck actuator rebuilt

* New 85mm chuck fitted, also have the 5C collet closer

* Panels sandblasted and powdercoated

* New stepper motors fitted

* 2K painted several components

It is dummy assembled at the moment

I still need to powdercoat the base now and cut some perspex to fit the door etc

re-assemble and she will be up and running again.

This machine was good before, should be like new when finished. This is the only Emco 120P cnc I know of in Perth and one of 6 I know of in the country. I would love to get my hands on a few more of these machines and enough work too keep them busy full time.

I have retained the original stepper pulleys and belts

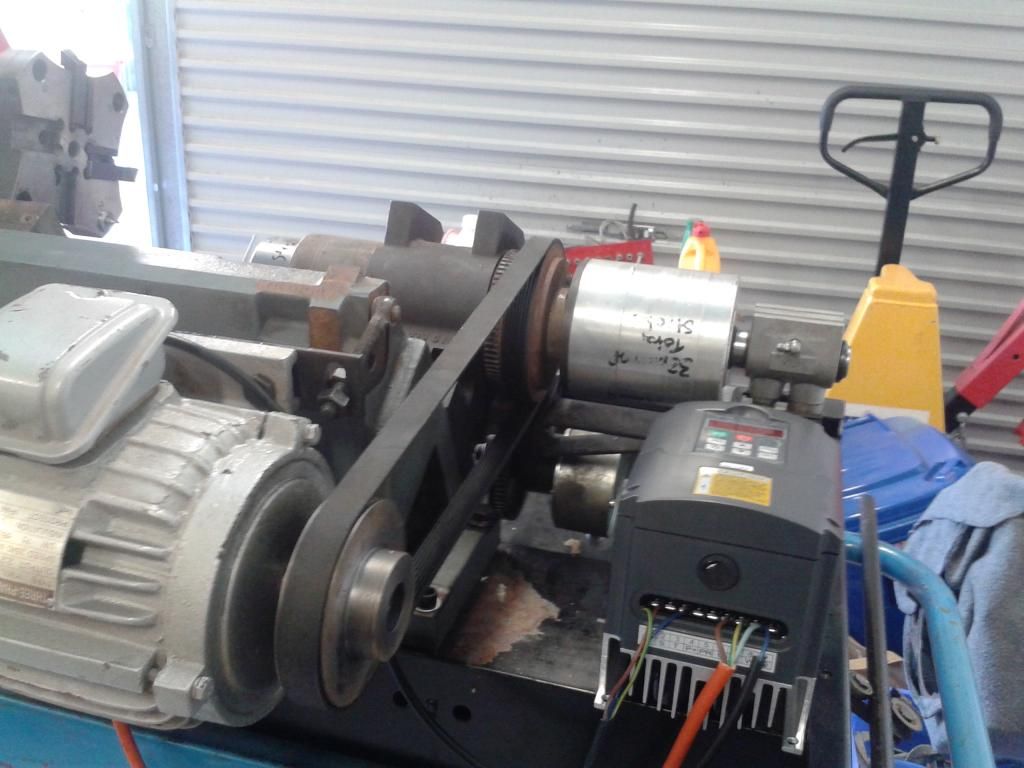

There is a 2.2kw 3 phase and vfd motor mounted, (5000 rpm spindle)

I am running an Andrew Barrow etc board for the atc.

I am going to run a mini atx motherboard and stepper drives, b/o board etc all mounted in the original electrical box mounted on the side of the machine

This is when I first purchased the machine

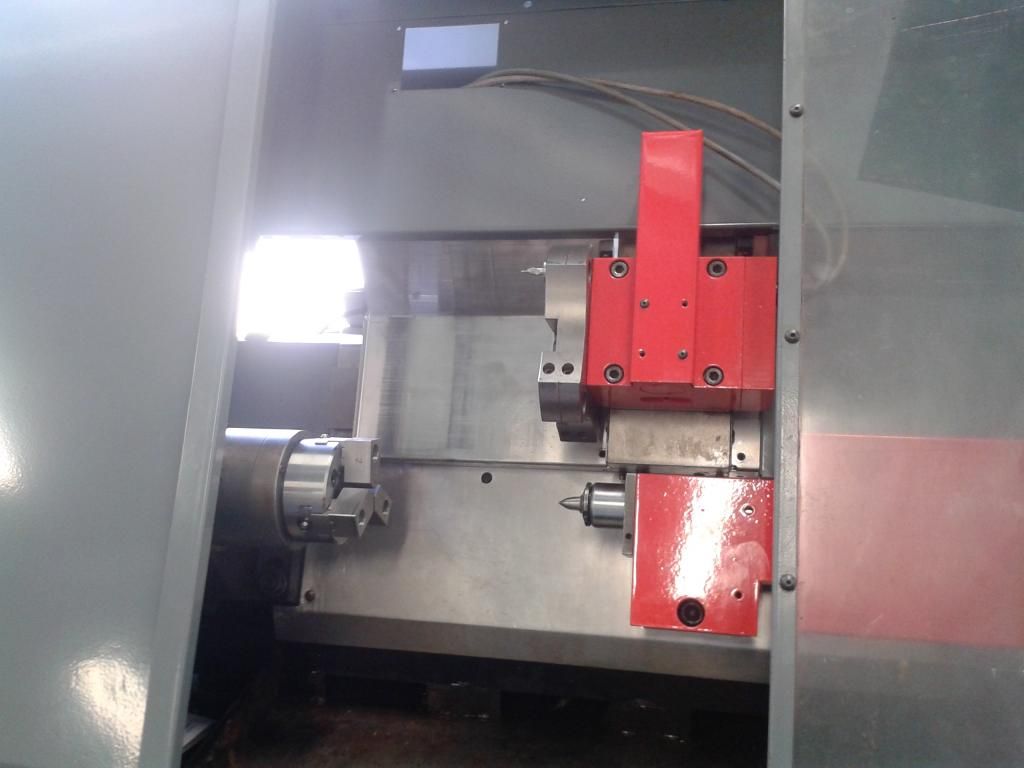

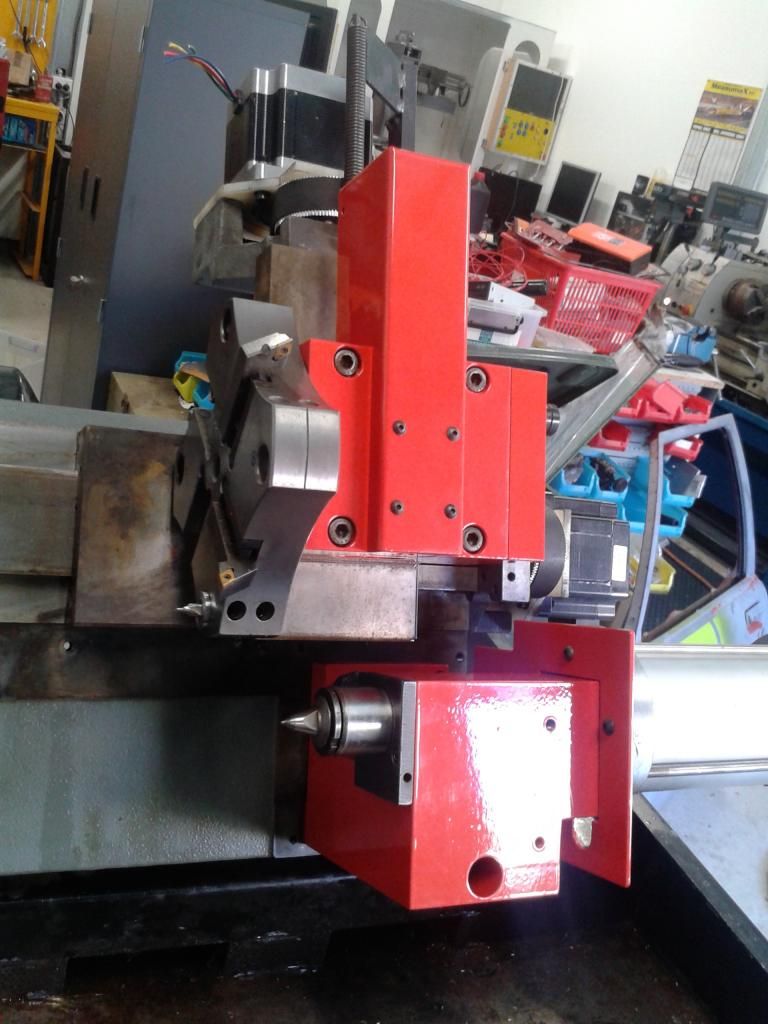

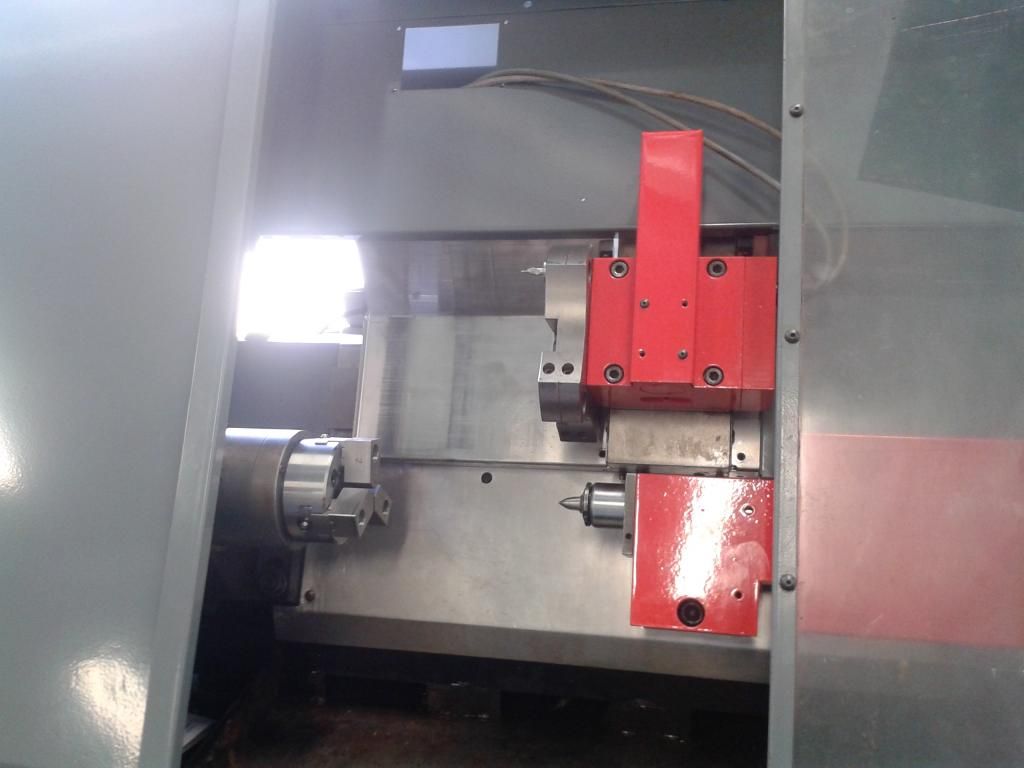

Here is a couple of pictures after rebuilding the ATC,tailstock etc and painiting with 2K paint

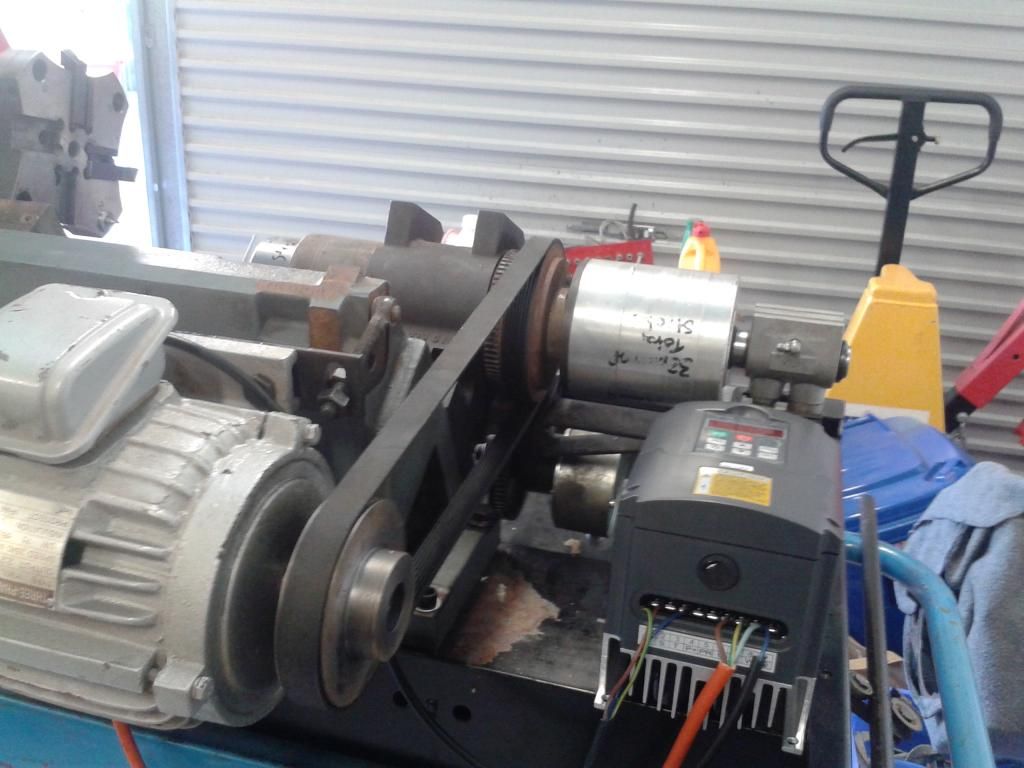

Here is a of picture of the 2.2kw motor and vfd

I made a new motor pulley to suit the motor shaft. The old pulley was seized on the original spindle drive.

the Autogrip 3P-03 chuck that I found.

This chuck mounts directly to the spindle although needs an adaptor for the actuator-chuck made

And a few pictures of the panels after powder-coating. The base still needs to be done and I also have taken the old stickers off very carefully and my local sign writer is making some new ones for me which will be identical.

This is a pretty basic build compared to some of the other tasks I have undertaken so I don't know what else to say really. The pictures don't do it much justice. It looks great in real.

Cheers.

Baz.

Soooo

this is where I am at.

The Emco 120P lathe has had a birthday,

* Spindle rebuilt

* Auto tool turret rebuilt

* Auto Tail-stock rebuilt

* Chuck actuator rebuilt

* New 85mm chuck fitted, also have the 5C collet closer

* Panels sandblasted and powdercoated

* New stepper motors fitted

* 2K painted several components

It is dummy assembled at the moment

I still need to powdercoat the base now and cut some perspex to fit the door etc

re-assemble and she will be up and running again.

This machine was good before, should be like new when finished. This is the only Emco 120P cnc I know of in Perth and one of 6 I know of in the country. I would love to get my hands on a few more of these machines and enough work too keep them busy full time.

I have retained the original stepper pulleys and belts

There is a 2.2kw 3 phase and vfd motor mounted, (5000 rpm spindle)

I am running an Andrew Barrow etc board for the atc.

I am going to run a mini atx motherboard and stepper drives, b/o board etc all mounted in the original electrical box mounted on the side of the machine

This is when I first purchased the machine

Here is a couple of pictures after rebuilding the ATC,tailstock etc and painiting with 2K paint

Here is a of picture of the 2.2kw motor and vfd

I made a new motor pulley to suit the motor shaft. The old pulley was seized on the original spindle drive.

the Autogrip 3P-03 chuck that I found.

This chuck mounts directly to the spindle although needs an adaptor for the actuator-chuck made

And a few pictures of the panels after powder-coating. The base still needs to be done and I also have taken the old stickers off very carefully and my local sign writer is making some new ones for me which will be identical.

This is a pretty basic build compared to some of the other tasks I have undertaken so I don't know what else to say really. The pictures don't do it much justice. It looks great in real.

Cheers.

Baz.

Last edited:

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

Hi Greg. I can't remember the exact spec but the bearings were a greased angular contact type

Last edited:

Similar threads

- Replies

- 5

- Views

- 3K

- Locked

- Replies

- 6

- Views

- 3K