I've finally gotten far enough along that it's looking like it might be an engine someday.

Also, I have a question... after I get it running, I want to try the sandblasting trick on the base to get that cast look. How fine should I get the finish before sandblasting? I don't want any tool marks to show.

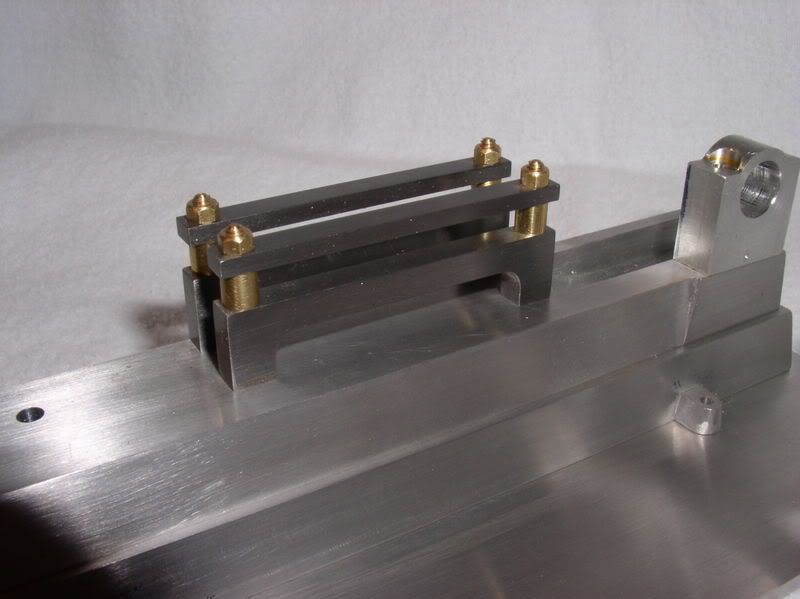

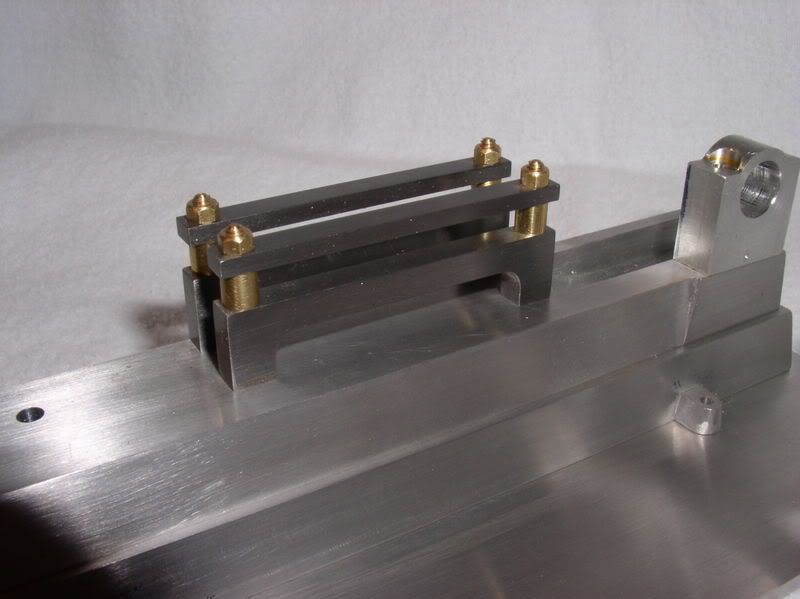

Details of the crosshead guides:

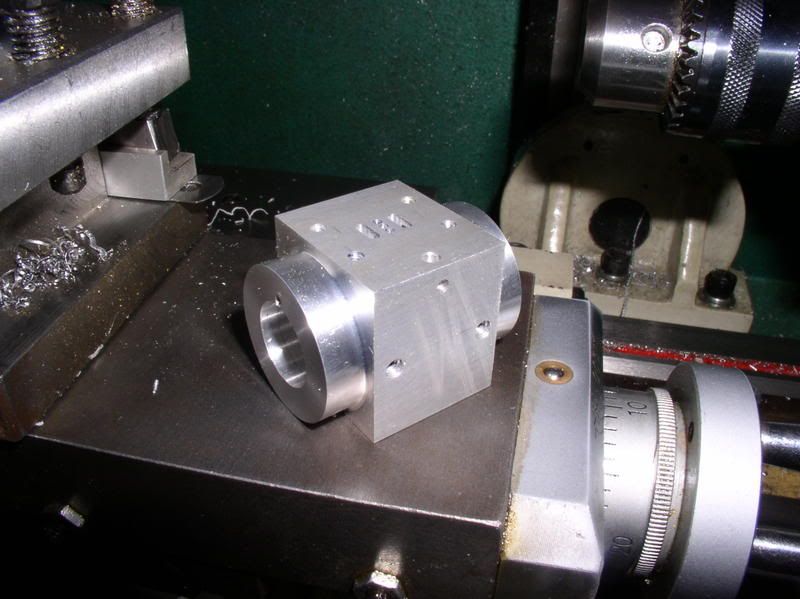

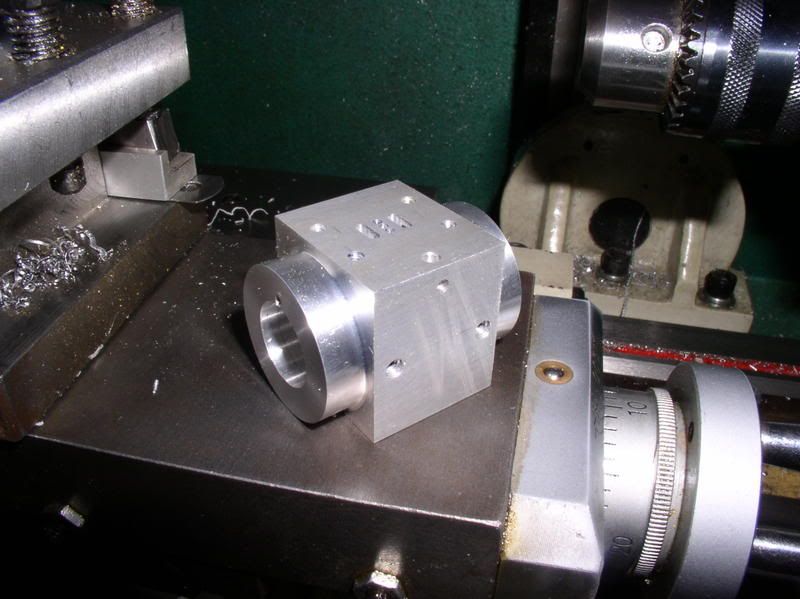

I'm currently working on the cylinder. I've got 12 holes to drill and tap for the heads, plus hogging out the middle where the lagging goes. All the porting is finished.

At the rate I work, it will probably be next summer before I'm finished. I'll try to do a better job of posting progess pictures from here on out.

Dave

Also, I have a question... after I get it running, I want to try the sandblasting trick on the base to get that cast look. How fine should I get the finish before sandblasting? I don't want any tool marks to show.

Details of the crosshead guides:

I'm currently working on the cylinder. I've got 12 holes to drill and tap for the heads, plus hogging out the middle where the lagging goes. All the porting is finished.

At the rate I work, it will probably be next summer before I'm finished. I'll try to do a better job of posting progess pictures from here on out.

Dave