rodw

Well-Known Member

- Joined

- Dec 2, 2012

- Messages

- 1,146

- Reaction score

- 340

Hi RodW

Wasn't there a problem encountered with counting such large numbers of pulses? something about "rounding" number of steps or pulses ?

Perhaps this was only in Chuck's original sketch.

xpylonracer

I think in Chuck's original code, he may have used floating point maths which can result in rounding errors. I don't use floating point maths. Instead I reduce all angles to seconds of a degree so 360 x 60 x 60 = 1,296,000 divisions in a circle. That way rounding results in +- 1 second of a degree.

Accuracy is dictated by the number of steps your stepper takes and your final drive ratios. Microstepping increase resolution to a certain extend but if you are microstepping (I can use 40 x microstepping with LinuxCNC, or 8000 steps per rev) but that does not mean that I can achieve accuracy of 360/8000 of a degree. Do your own maths to determine what angle you can do per step.

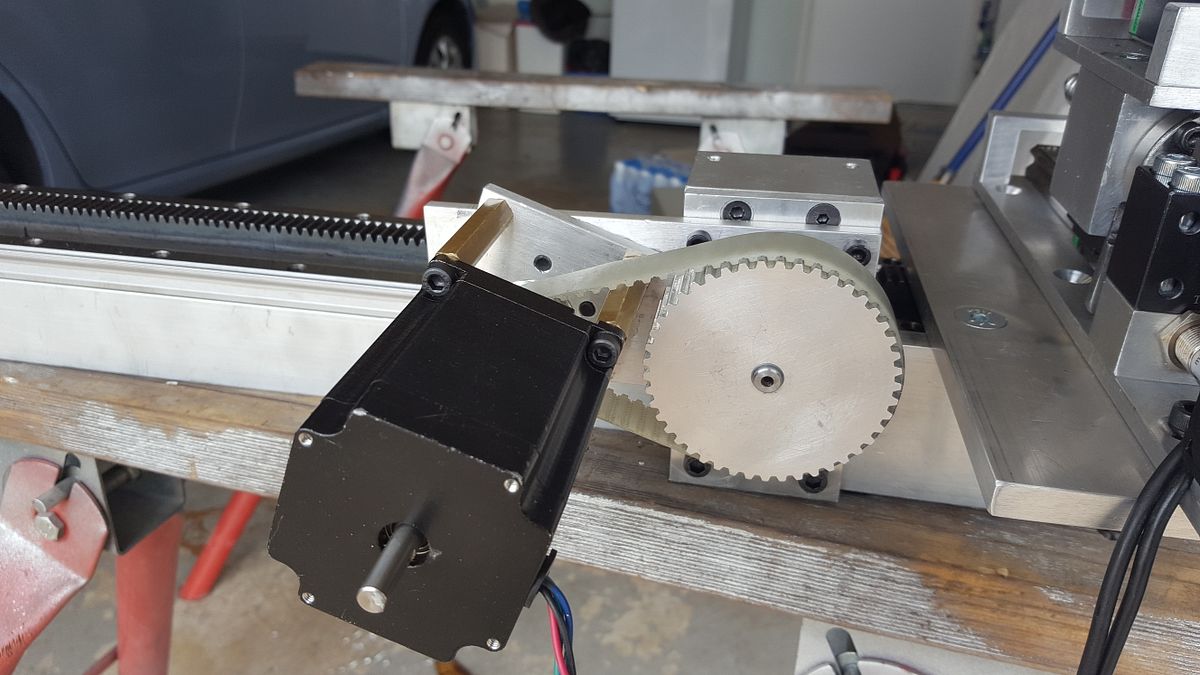

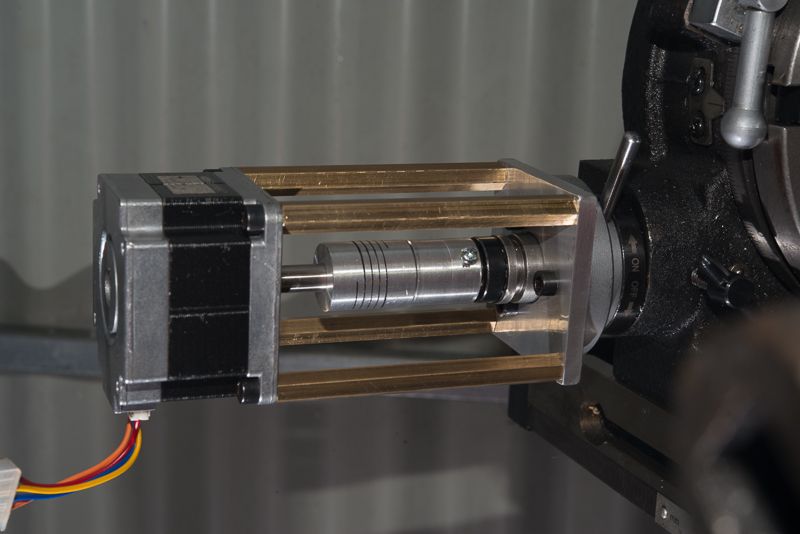

I would look carefully at the gearboxes you are considering, unless you spend a few hundred $, the backlash is around 1.5 degrees. You will get less backlash with a timing belt and there are plenty adding them to rotary tables. Heres a 3:1 I've built for a pinion drive.