I've been clumsy enough to break another M3 tap and need to remove its remains. Most of the spark eroders I've seen use a wire which is fed into the work and a current limit, usually light bulbs. This leads to continual wire adjustment. However on you tube I saw a spark eroder using a door bell coil burning a hole through a razor blade. The nice thing was that the wire automatically advanced and as soon as contact was made a coil in series with the electrode pulled the electrode away, generating a continuous spark with no gap adjustment needed.

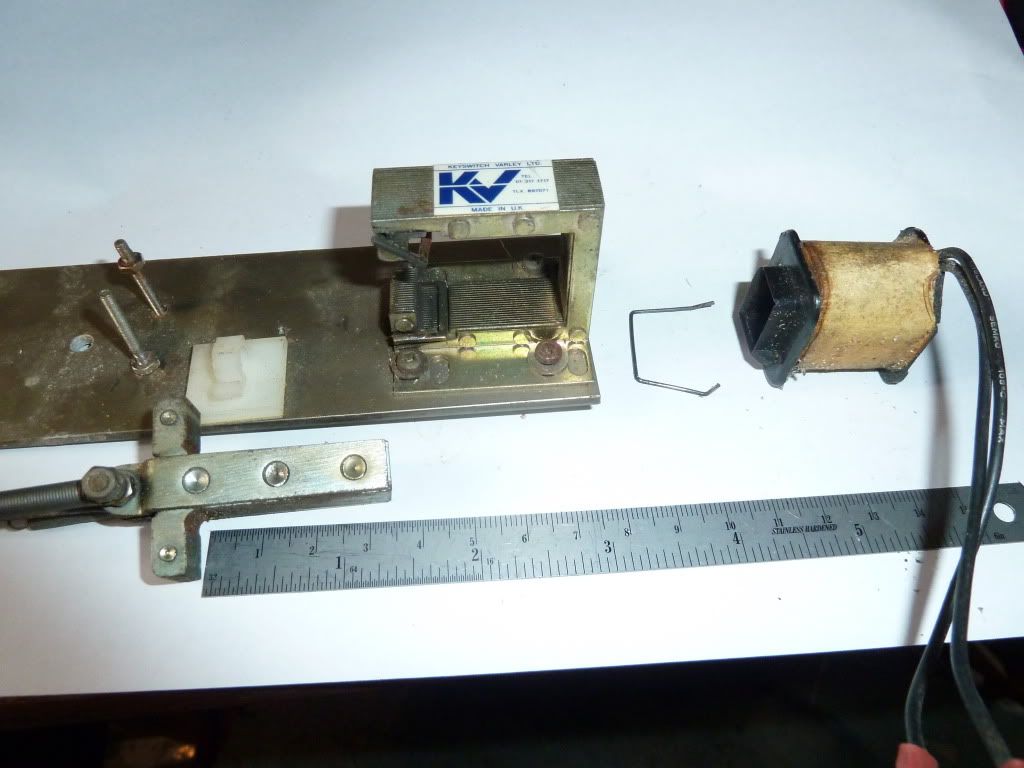

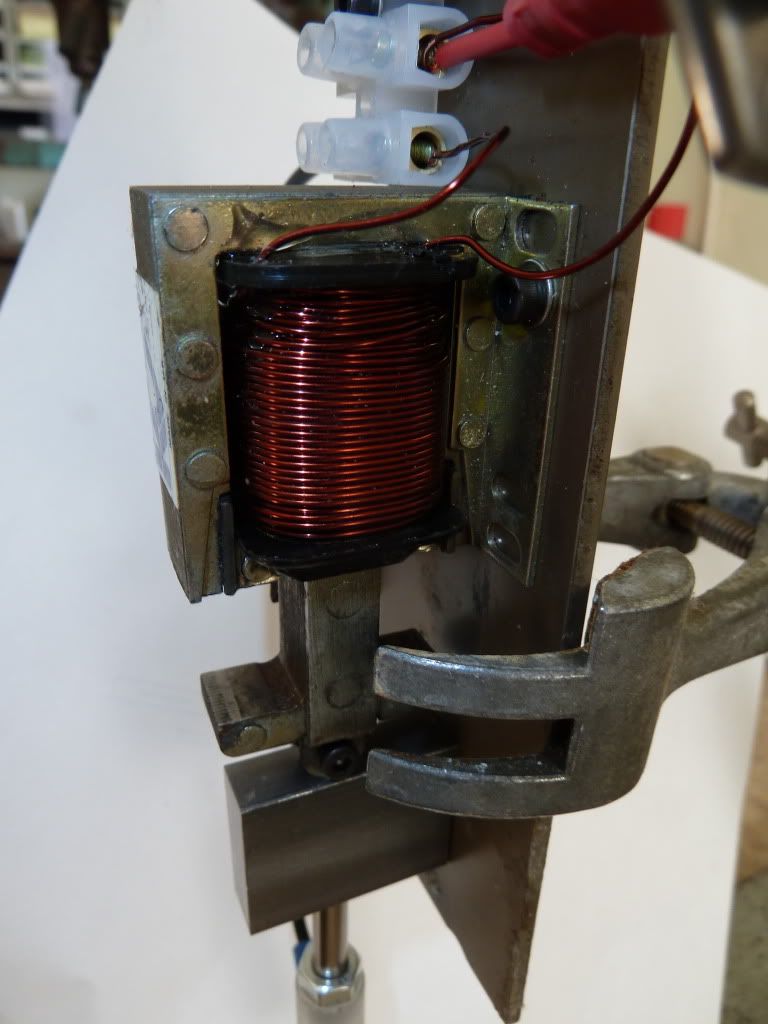

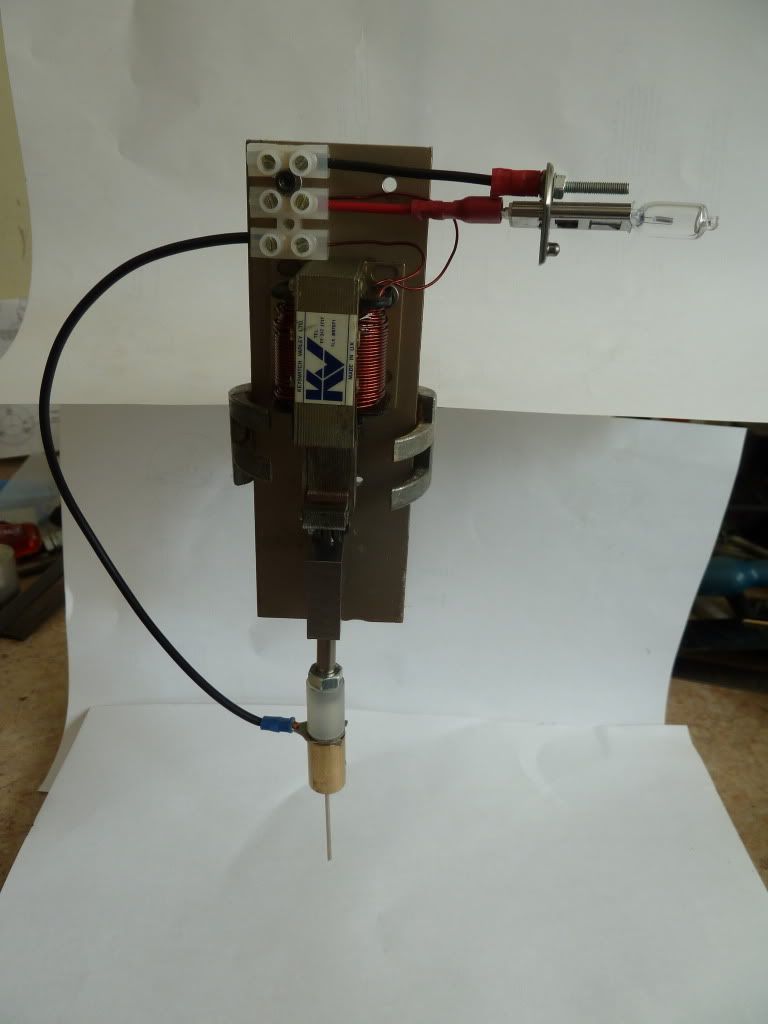

I thought I might lash up a solenoid or old relay and see if it would be viable.

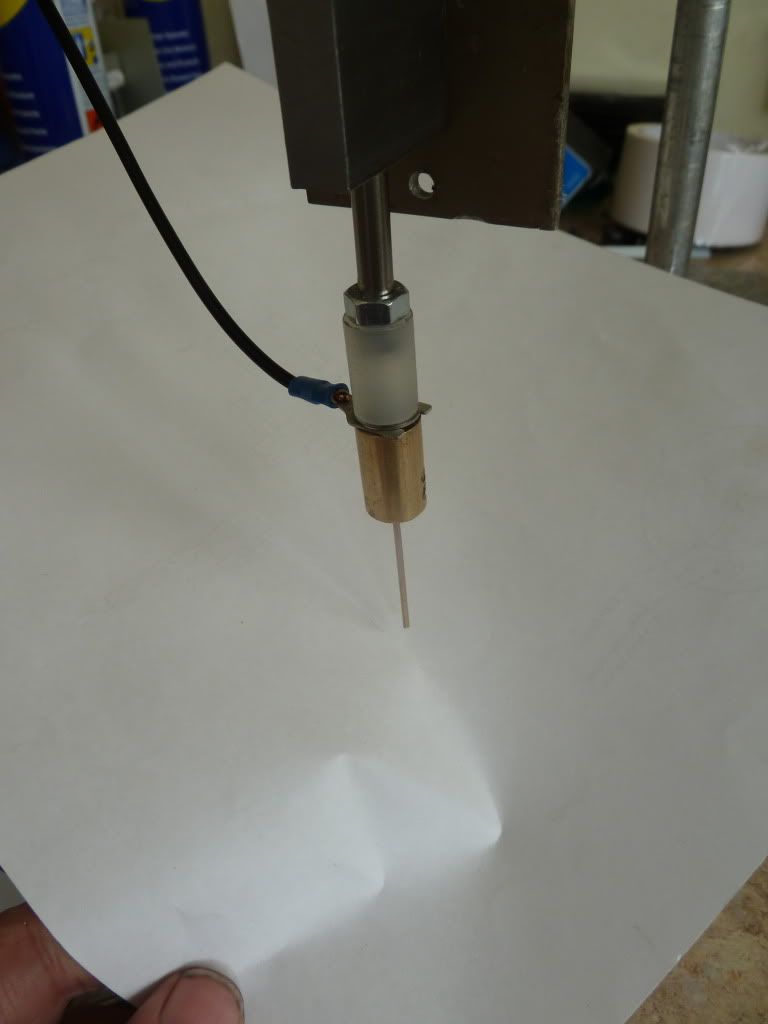

I plan on using a piece of piano wire for the electrode. Not sure if it would need oil or liquid immersion as the erosion is done by the very high voltage spark generated from the coil.

Has anyone else used this relatively crude technique for tap removal ?

Will post pictures if it works/doesn't work/explodes ;D

Best Regards

picclock

Link to youtube video

http://www.youtube.com/watch?feature=player_embedded&v=uUN4_-xp1Wc#!

I thought I might lash up a solenoid or old relay and see if it would be viable.

I plan on using a piece of piano wire for the electrode. Not sure if it would need oil or liquid immersion as the erosion is done by the very high voltage spark generated from the coil.

Has anyone else used this relatively crude technique for tap removal ?

Will post pictures if it works/doesn't work/explodes ;D

Best Regards

picclock

Link to youtube video

http://www.youtube.com/watch?feature=player_embedded&v=uUN4_-xp1Wc#!