arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

Thm: Good to hear that Chris

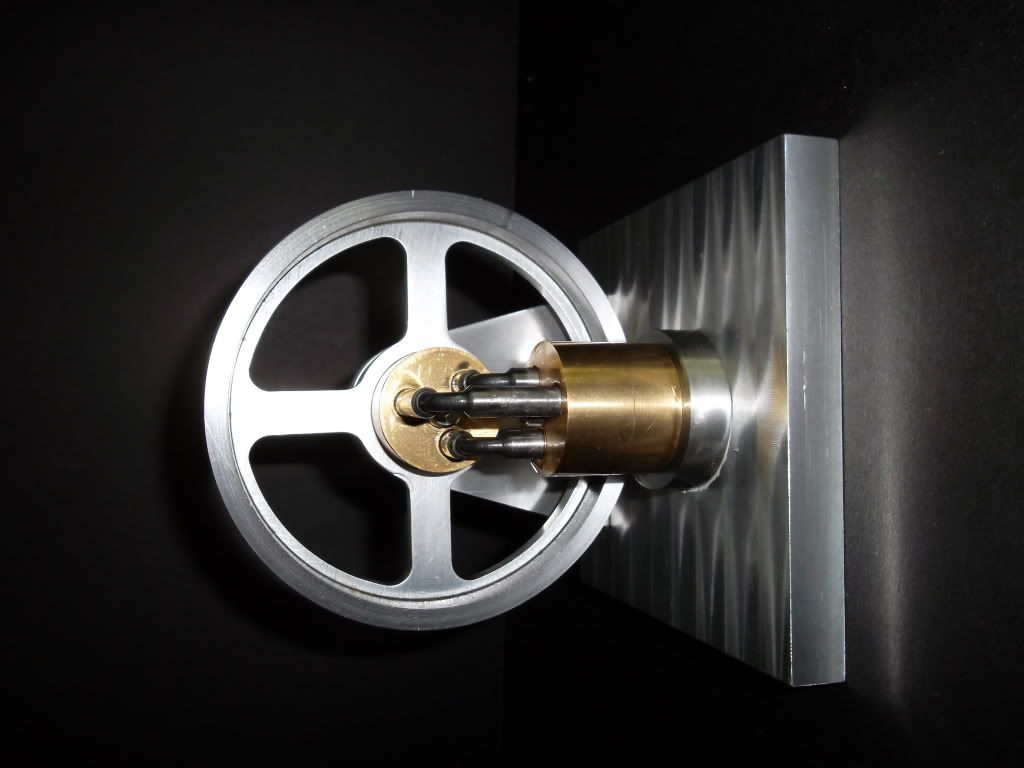

Could the flywheel weight be pulling the bearing block out of square when it's vertical ? - also check the fit of the axle screws; they need to have close tolerances - no wiggle; just a good running fit.

Kind regards, Arnold

Could the flywheel weight be pulling the bearing block out of square when it's vertical ? - also check the fit of the axle screws; they need to have close tolerances - no wiggle; just a good running fit.

Kind regards, Arnold