Hi Owen, Most Silver Solders are used around 630~750deg. C.

Bronze brazing a couple of hundred degrees hotter.

I would have to check on appropriate joining for stainless steel. I think that is what Bluejets is suggesting you do?

I have started working on an explanation of an annular discharge silencer... that I designed near 40 years ago....

I'll send what I have prepared,

if you wish - directly to you, in case it is of some use?

Here is a schematic.... but it has not copied all the lines on the drawing... so this is not exactly correct! (to protect the innocent?). Don't bother copying this schematic, as it will be as loud as an open pipe.

View attachment 134226

Trouble is, it was "Company Business" (I.E. not my "intellectual property", as the employee!) - so when I left, all my papers had to remain on site (pre-computer anyway!). SO it is an "Hypothetical memory" of what may - or may not - be true. (Protects the innocent, because it is not exactly accurate!).

K2

Hello Steamchick

There is no secret in this silencer.

I first read about the annular gap silencer in Blair's book (R-186). And I found a lot of information on this silencer.

In [3] Blair shows that the minimum annular gap is 3.2 mm. But if you consider that a two-stroke engine throws out unburned oil and carbon deposits form inside the silencer, then Blair recommends an annular gap of 3.5 mm.

"This annular dimension is on the borderline for potential carbon build-up and resultant clogging, so a value of XAN of 3.5 mm is probably a more pragmatic"

Blair recommends a 15% larger annulus area than the muffler inlet pipe area.

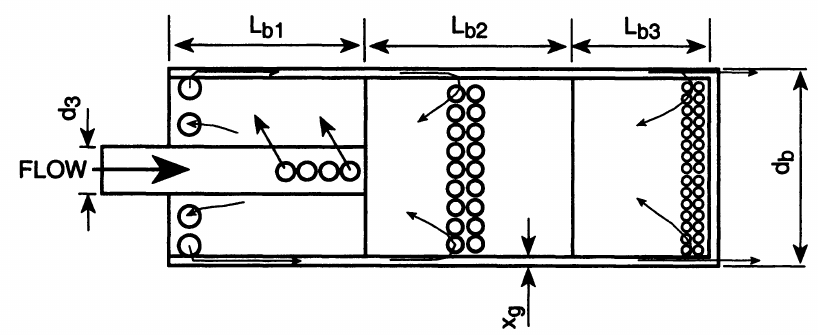

The most advanced silencer design is presented by Blair in [4].

The first expansion chamber, further the exhaust gas exits through a narrow annular gap. 2 and 3 chambers are wide-band Helmholtz resonators. As Blair writes in [4]):

"There are several other factors that contribute toward the overall effectiveness of this

silencer:

(i) The effilux of hot exhaust gas occurs through an annular ring into air that is at a much

lower temperature and higher density. There is a large contact area between the two

surfaces. This produces considerable damping ofthe turbulence in the exiting exhaust

gas plume, thereby reducing the high-frequency noise inherent in that source. This

approach to silencing turbulence noise is conventional practice for aircraft gas tur-

bines.

(ii) The central body houses side-resonant cavities that can be used to tune out particular

frequencies with a high noise content. The flow passing the entrances to these cavi-

ties is moving at right angles to those apertures, and at particle velocities that are

closer to acoustic levels than those in the conventional silencers shown in Figs. 7.7

to 7.9. Thus, the assumptions inherent in acoustic theory for Helmholz resonators

[7.36] are approached more closely, and the application of that theory can be applied

with a little more confidence in the quality of the outcome.

(iii) The exhaust pressure pulsations entering the first chamber, a diffusing silencer sec-

tion, have the normal and considerable amplitude associated with such waves. The

first box reduces the magnitude of the pressure oscillation before it enters the annu-

lus en route to the atmosphere, passing the several resonant cavities as it goes. How-

ever, the outside skin of the silencer does not experience the pressure forces due to

the full magnitude of the primary oscillation in the first box, as is the case with the

other silencers shown in Figs. 7.7 to 7.9, and so the outside skin vibrates less than it

does in those other silencers. Later on, Sec. 7.7 presents a discussion whereby double-

skinning of the outside of a conventional silencer may be necessary to prevent that

vibration from being a significant source off noise. That necessity may be eliminated

by using a laminar flow silencer."

The most difficult thing is to calculate the size and number of holes for 2 and 3 Helmholtz chambers. Blair gives a link to the numerical modal calculation method [5]. Other numerical acoustic calculation methods are not accurate for this type of Helmholtz resonator. Because these are Helmholtz resonators with distributed parameters, you need to know the wave function, differential equations, etc. Therefore, either do the calculation using modal analysis[5] or use programs for calculating by the finite element method FEM (or the finite volume method FVM). Nobody knows the frequency response of the motor. Therefore, I believe that first make a silencer, but do not drill holes in chambers 2 and 3. Start the engine with this silencer, measure the frequency response of the engine. Find the noisiest frequencies you want to dampen. Next, calculate the number and size of holes for 2 and 3 chambers of the Helmholtz resonator. Then assemble the silencer and again measure the frequency response of the muffler.

Why are these silencer not mass-produced? Because this silencer is not technologically advanced for quick production. In the modern world, all mass producers strive to make quickly, sell quickly, quickly and get a lot of money for a quickly made product. And in my personal opinion (and the opinion of philosophers), the decline of technology in modern civilization began in 2005-2008.

I have all the literature listed below in electronic form.

[1]

Geoffrey Roe: The Annular Discharge Silencer

[2]Journal of Sound and Vibration(1974) 33(1), pp. 29-39

THE SILENCING OF A HIGH PERFORMANCE MOTORCYCLE

G. E. Roe. (Receired 20 June 1973, and in revised form 25 September 1973)

[3] The basic design of two-stroke engines Gordon P. Blair. 1990 ISBN 1-56091-008-9

SAE Order No. R-104

Chapter 8 - Reduction of Noise Emission from Two-Stroke Engines

8.5.3.2 A possible absorption silencer segment for a two-stroke engine

pp. 382-385

[4] Design and Simulation of Four-Stroke Engines Gordon P. Blair 1999 ISBN 0-7680-0440-3 SAE Order No. R-186.

Chapter 7 - Reduction of Noise Emission from Four-Stroke Engines. 7.5.4 The Laminar Flow Exhaust Silencer pp. 723-725

[5] Free Gas Pulsation of a Helmholtz Resonator Attached to a Thin Muffler Element

Peter C.-C. Lai Copeland Corporation, Werner Soedel Purdue University

International Congress and Exposition, Detroit, Michigan, February pp.23-26, 1998