enginemaker1

Well-Known Member

- Joined

- Jul 1, 2009

- Messages

- 55

- Reaction score

- 0

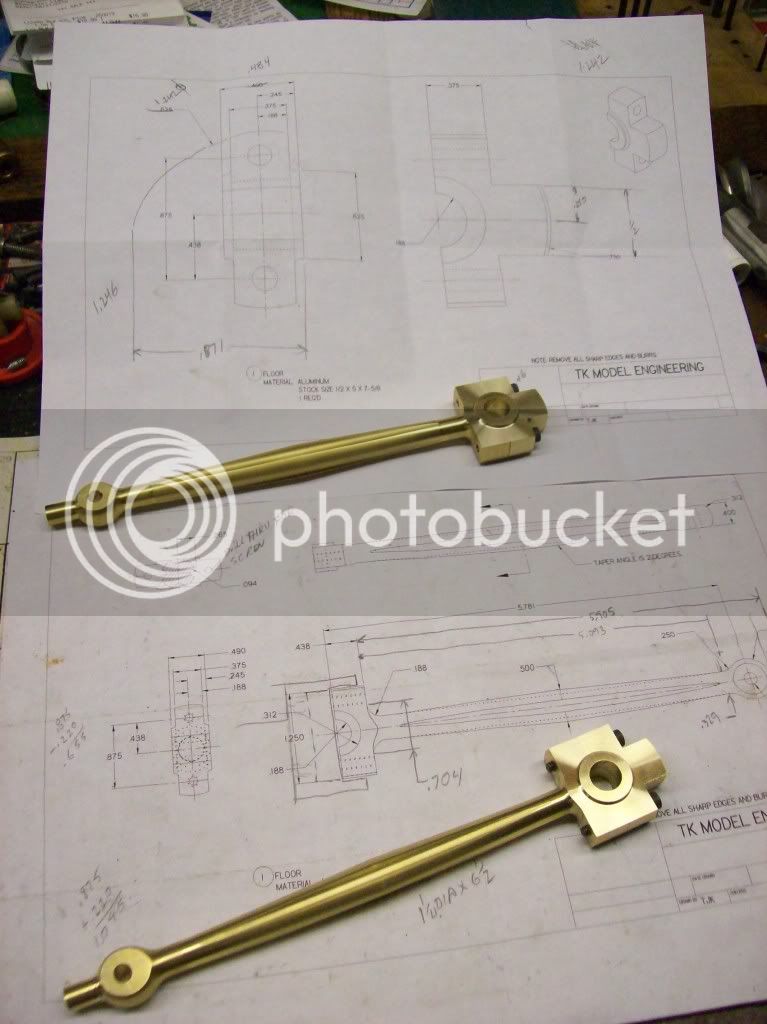

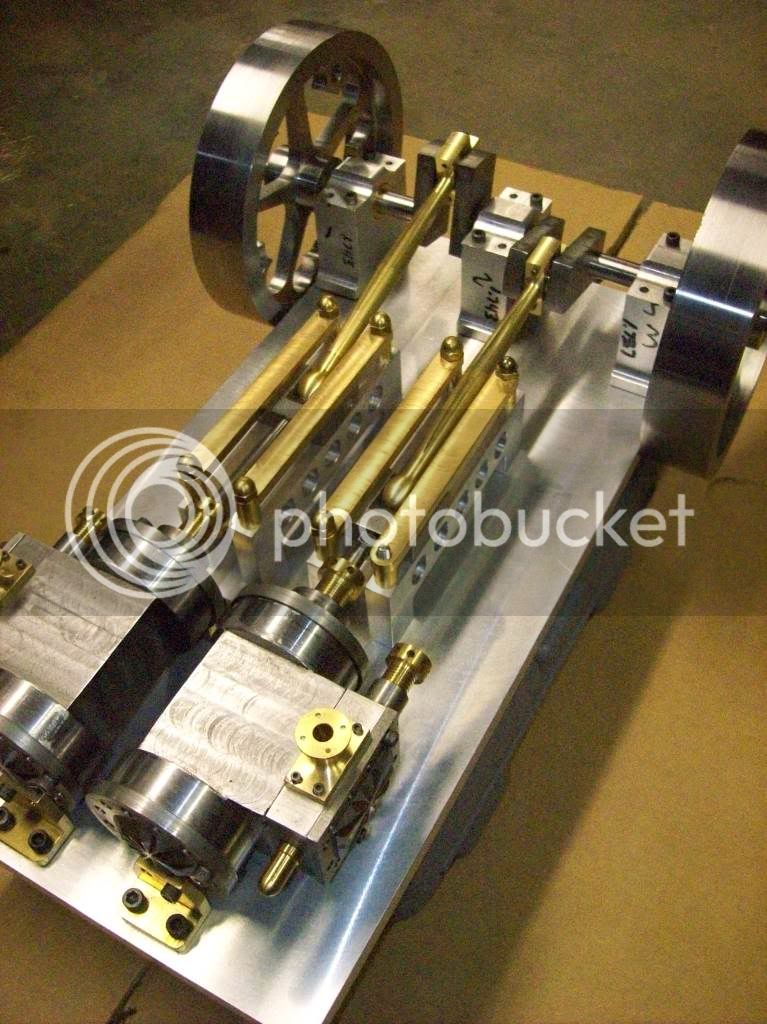

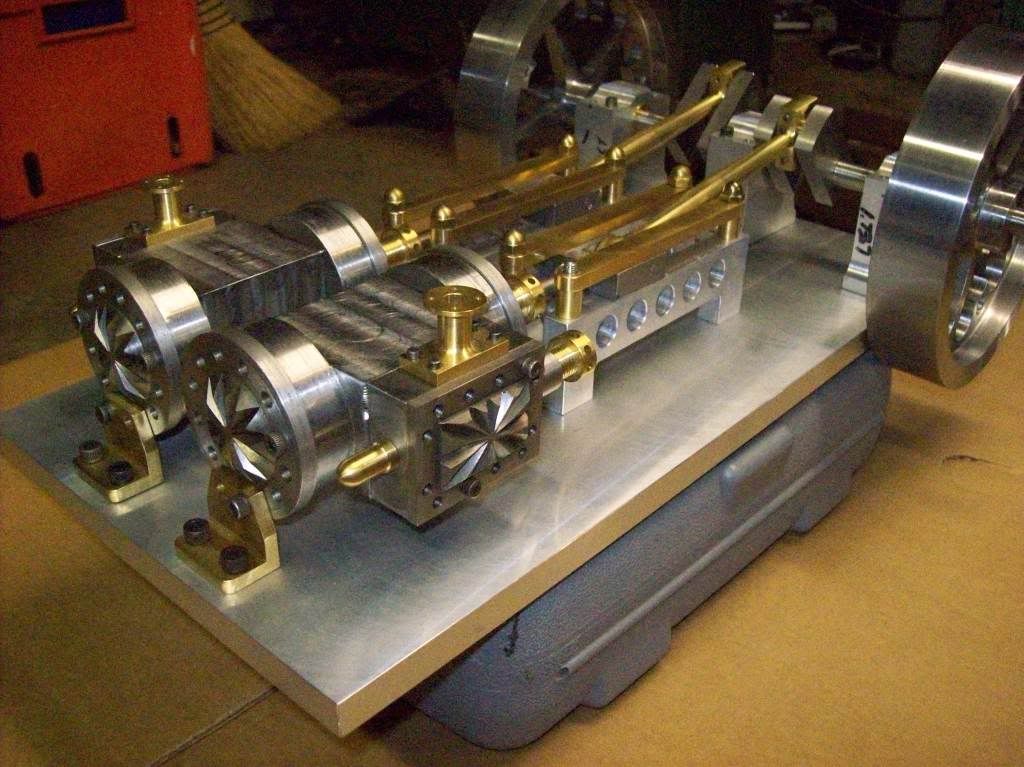

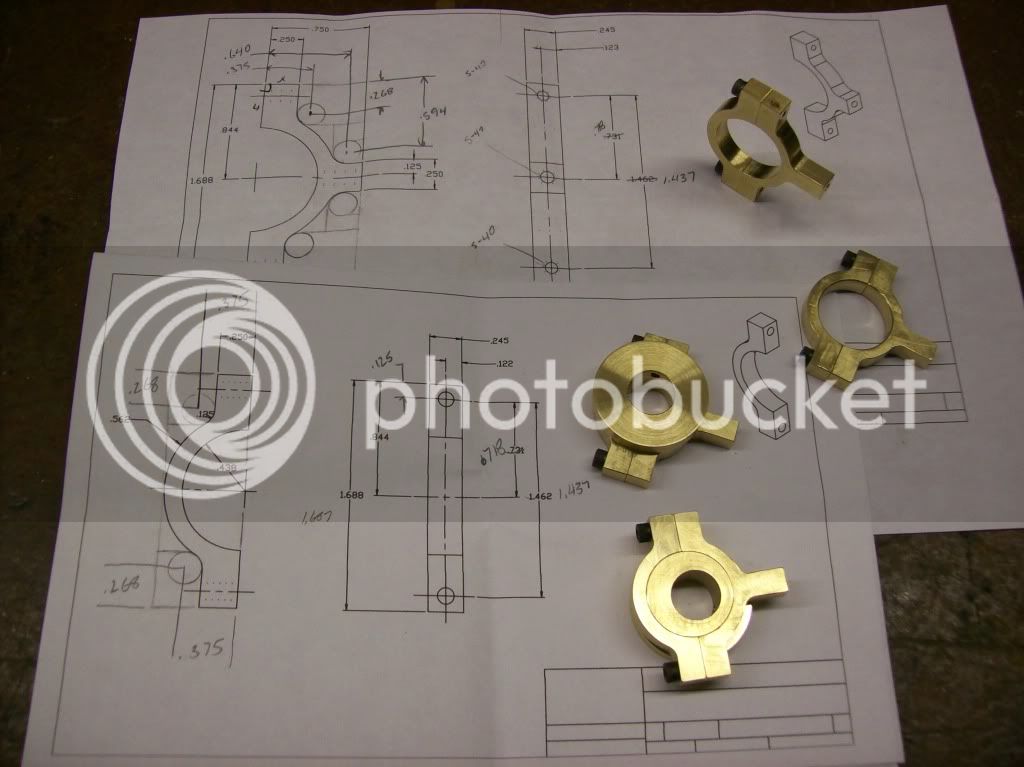

The following pictures show the progression of the steps I used in making the connecting rods.

Hi Stew,compspecial said:I've never seen a 6jaw chuck before.

Enter your email address to join: