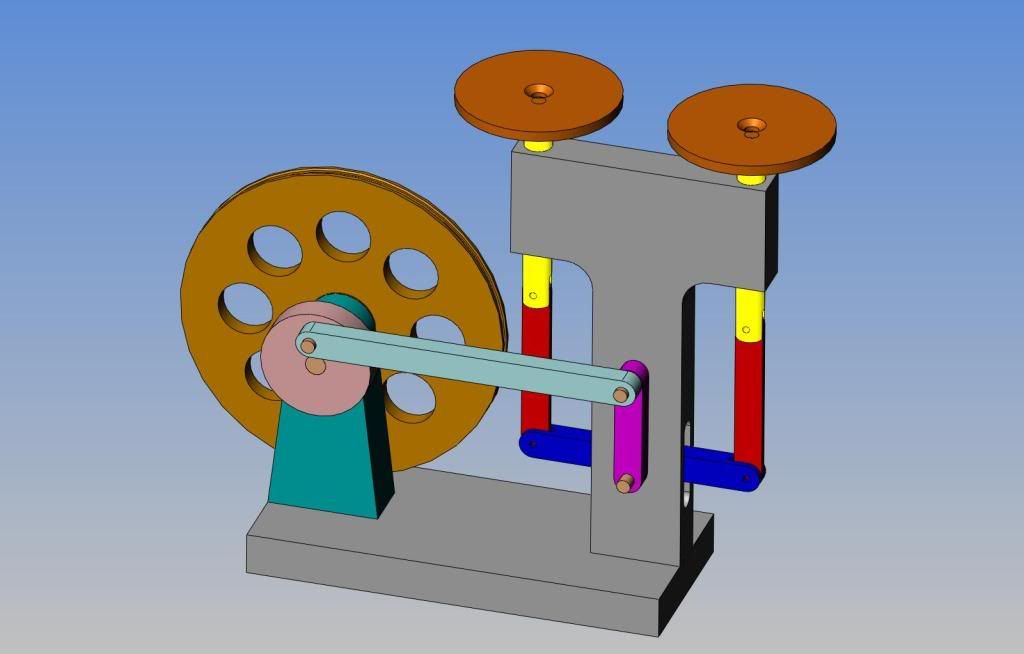

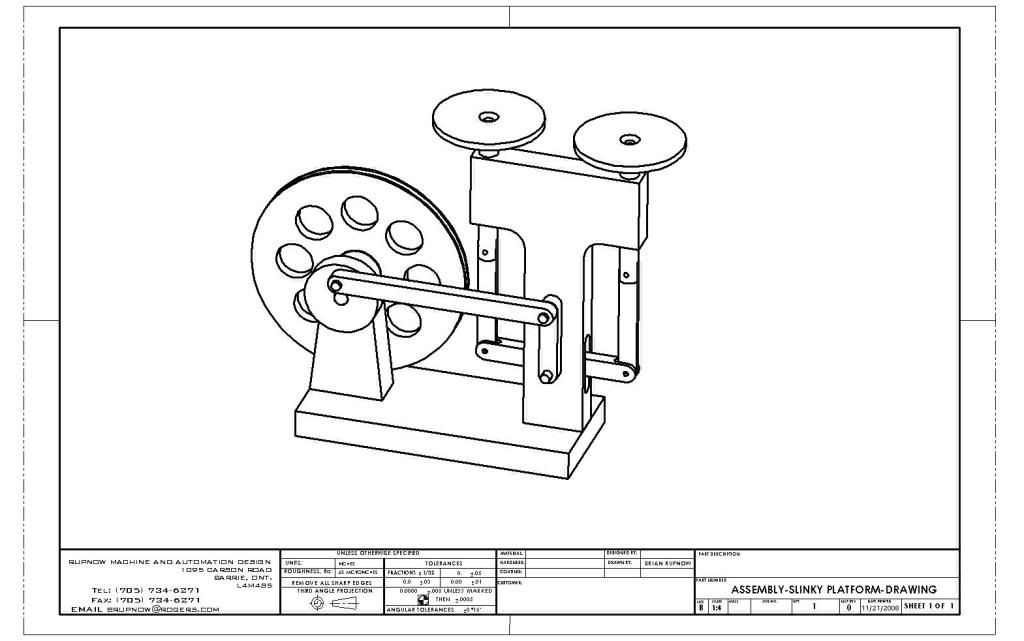

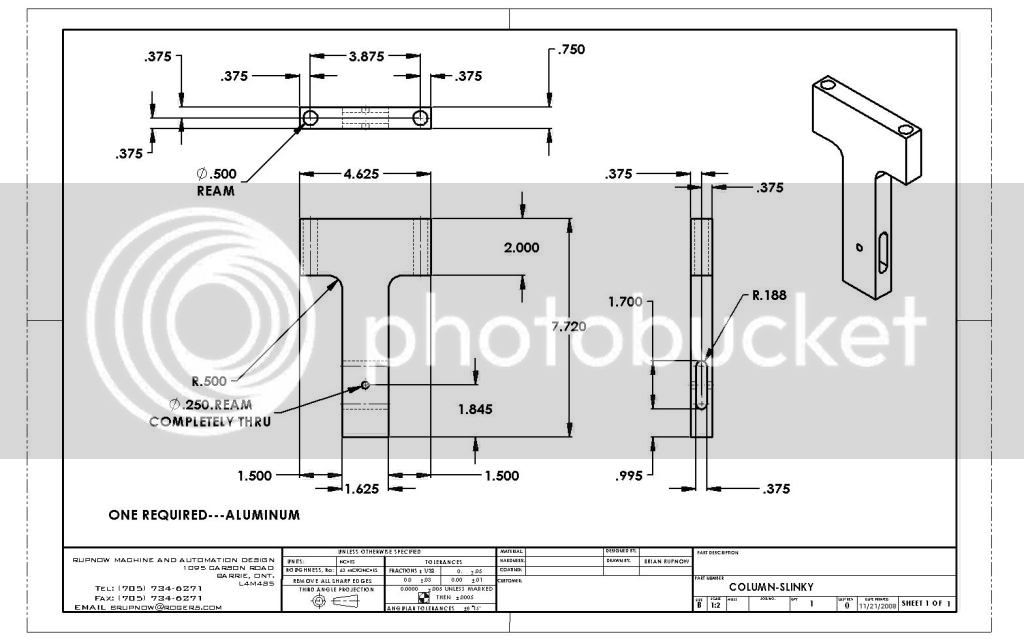

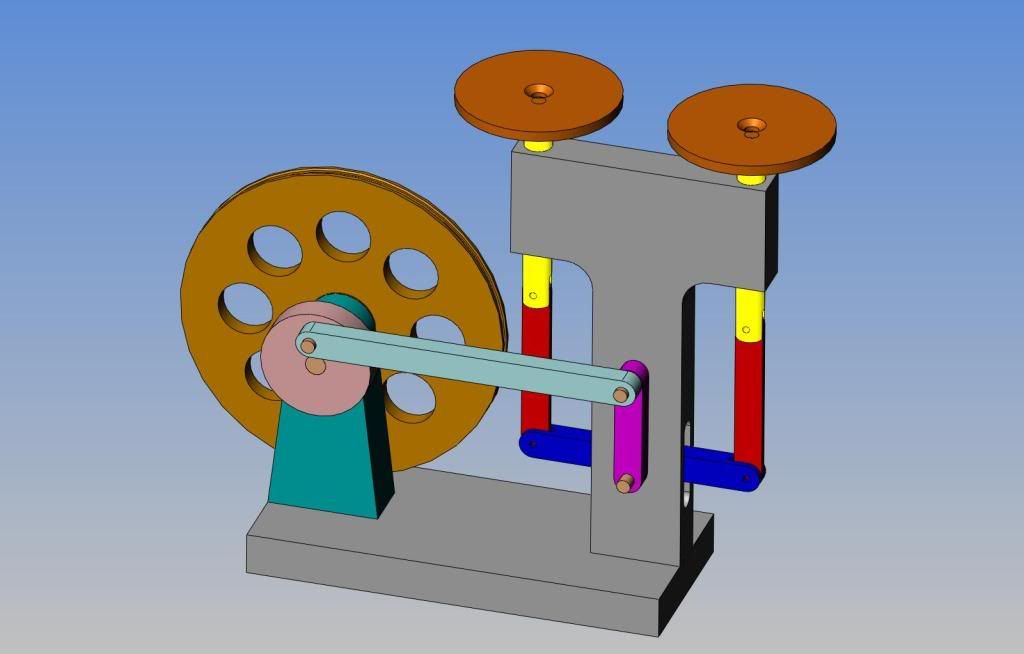

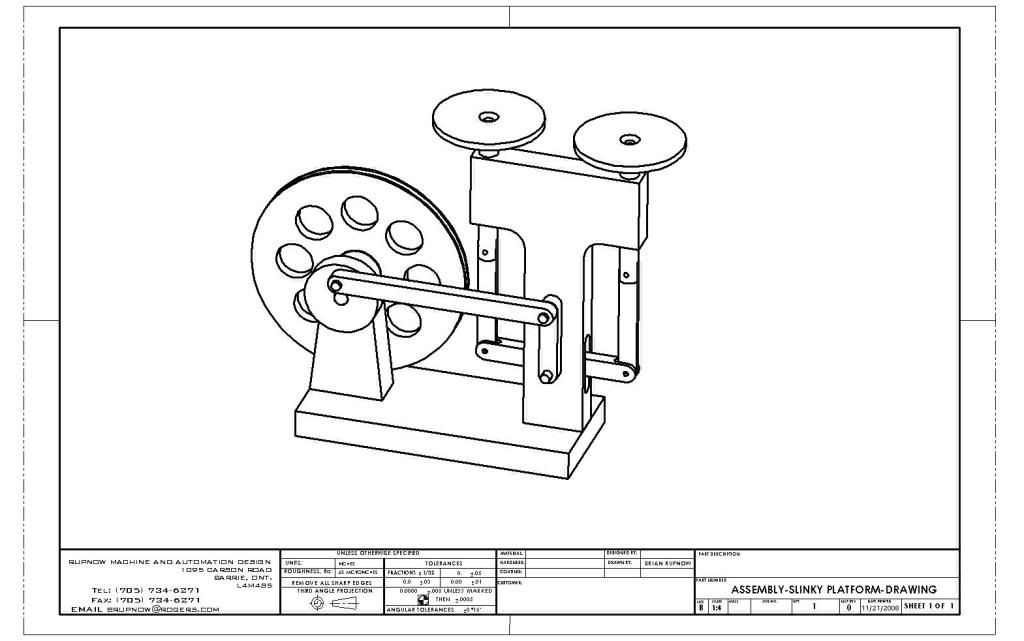

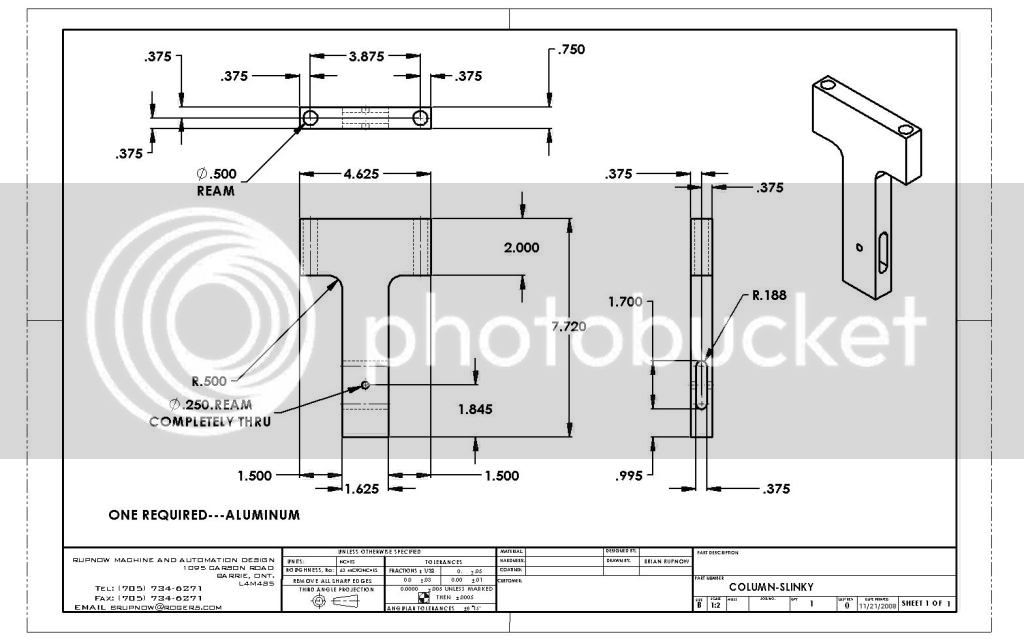

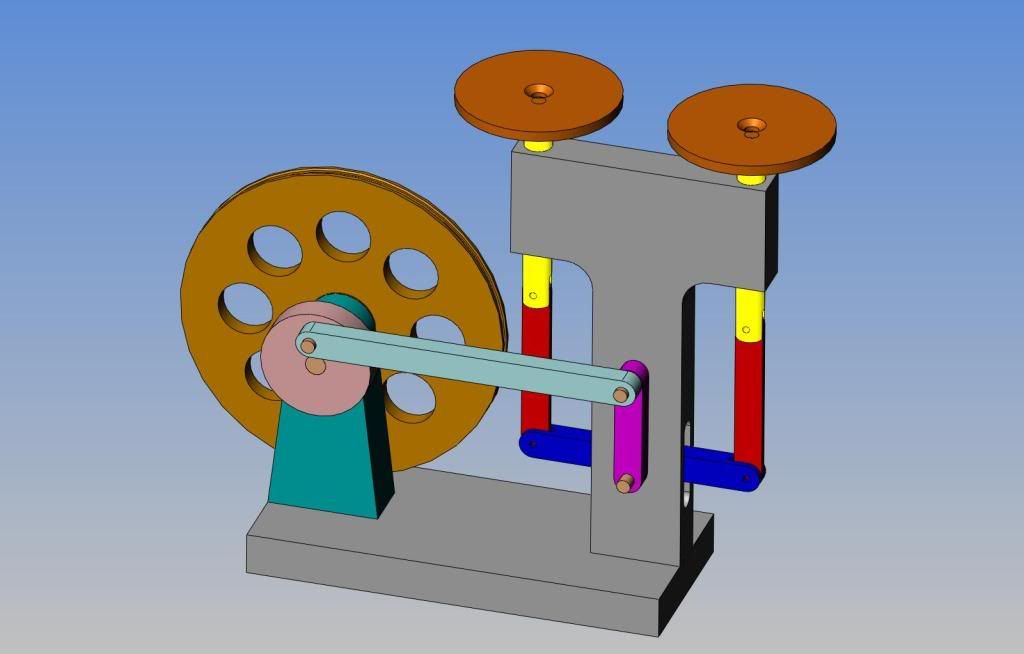

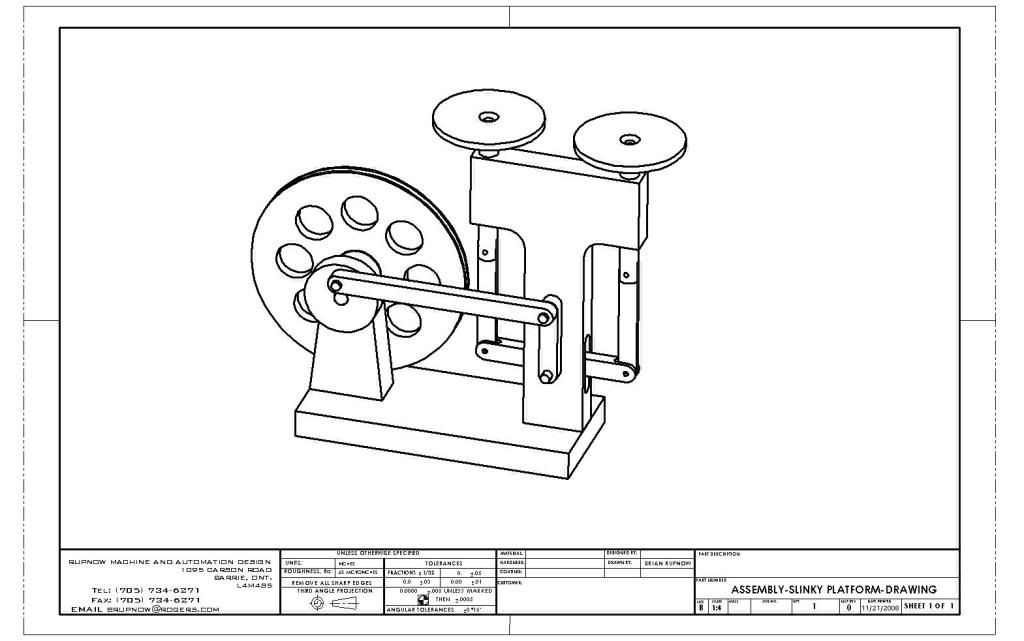

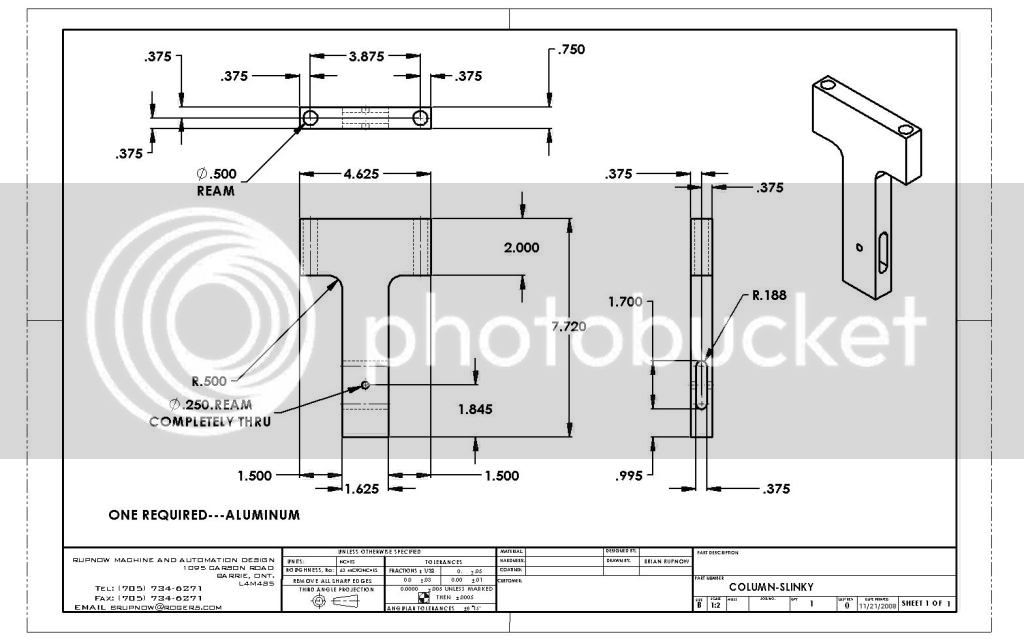

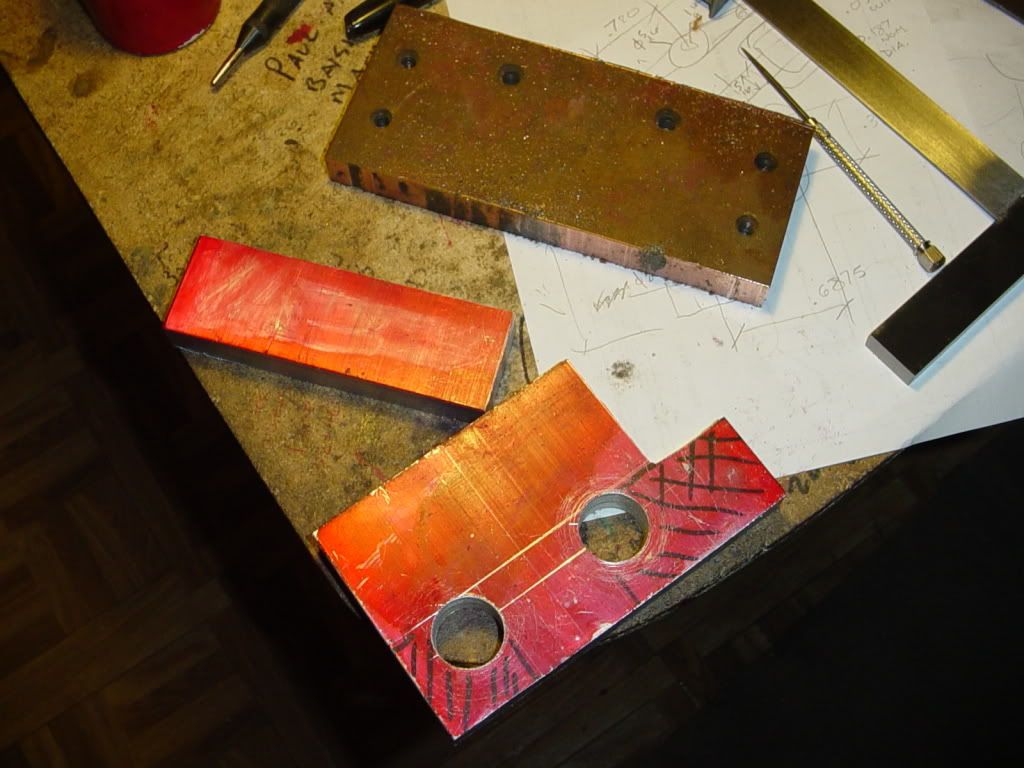

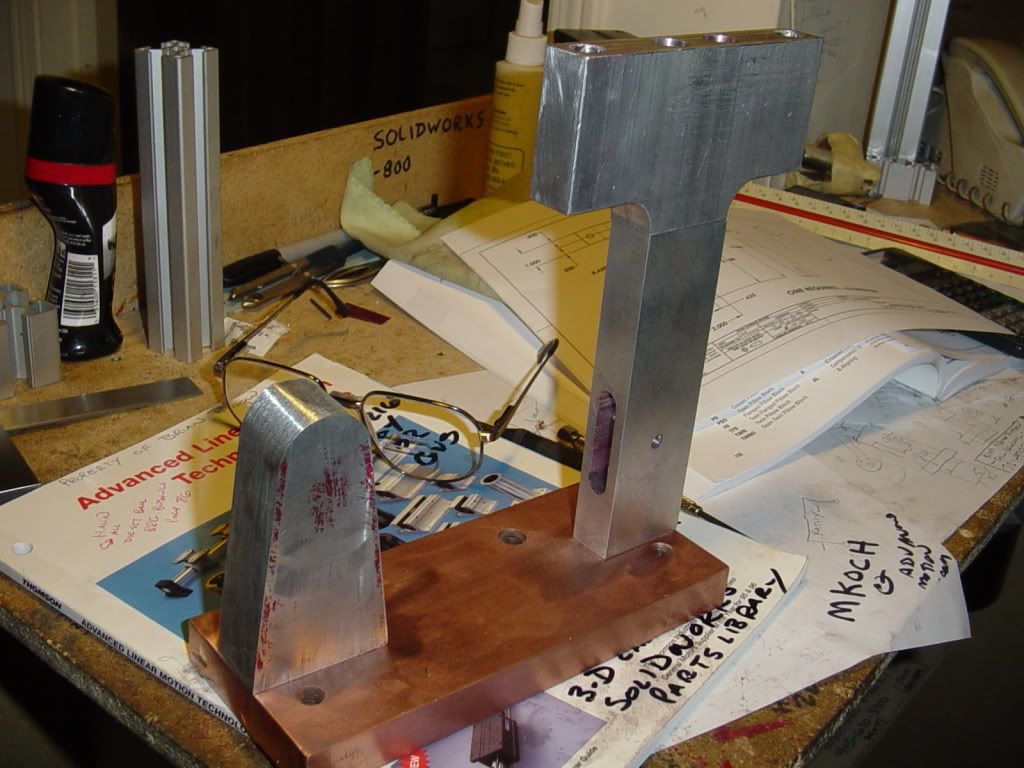

Due to the downturn in the economy, I'm going to build a slinky machine, because I don't have any real work.--And I do have 95% of the material here anyways.

cfellows said:Brian, you sure have a lot of energy! What's your secret? :bow:

Chuck

ksouers said:Brian,

This is really gonna be interesting.

Where in the world do you get all this energy, and where can I get some??

Hey---If it was for me, it would be put together, delivered, uncrated, and put in place by whoever I bought it from!!! For a 25 year old with enough gumption to finish university, get a great job, and buy her first place on her own, I don't have any trouble helping her out any way I can.tel said:How did you fall for that Brian? I avoid flat pak furniture like the plague.

Enter your email address to join: