- Joined

- May 27, 2010

- Messages

- 2,999

- Reaction score

- 1,171

"Old fashion hand grinding of twist drills is not that difficult to pickup. There are many YouTube videos on twist drill grinding. I was taught drill grinding in Trade School.

__________________

Gus,the Happy Boat-Fisherman and Happy Machinist.

(Jack of all Trades and Master of None)"

^^^^^ What 'e said.

Every 16-year-old first-year apprentice can sharpen a drill bit correctly. It is not a difficult skill to learn. Perhaps easier to learn firsthand from someone else rather that out of a book or off a video, but still not rocket science.

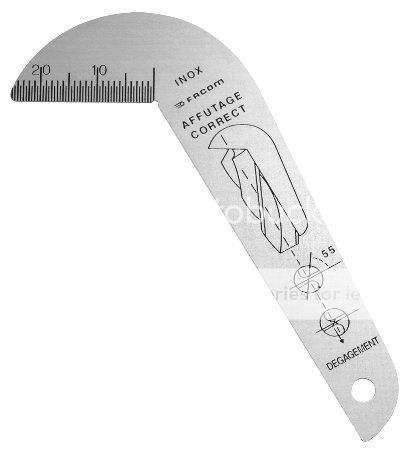

It may be helpful to get a drill gauge, a piece of sheet metal with the angle of the required cutting edge cut into it, with small graduations to help you get the two cutting edges equal length.

You can always have a try at sharpening a few larger drills then post pics on here and some of the old hands can give you advice on how you are doing. The closest you can get to firsthand one-on-one instruction.

For drill under about 2mm or 1/16", they can be sharpened easily on a simple oil stone on the bench. There are various drawings available on the net for small, easy to make fixtures that you clamp the drill into and then rub the whole block up an ddown your oil stone to sharpen the small drill to a four facet point.

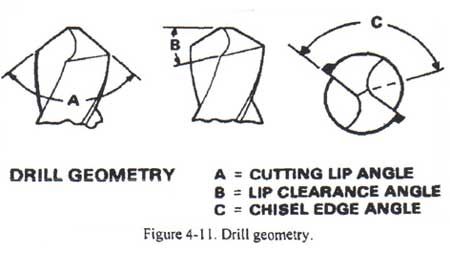

The number one shortfall I see with beginners sharpening drills is not grinding enough clearance onto the surface behind the cutting edge. This is the number one barrier to easy drilling. No clearance, no cutting. Just rubbing on the flat face.

So it pays to grind a bit of extra clearance on the "land" like the below pic at angle B

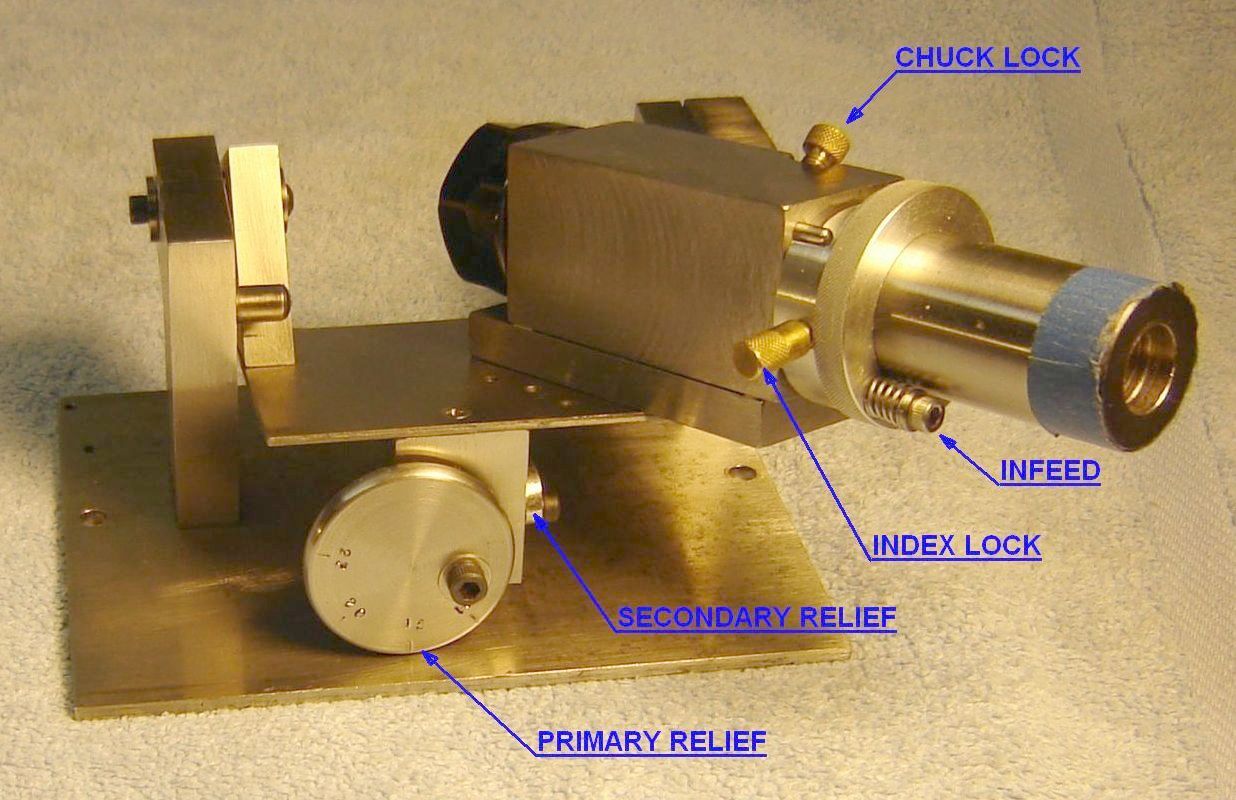

Here is all you need to get started on grinding your own.

Hi Hopper,

The drill bits issued to us from the Trade School tool counter were in a bad shape. Instructor passed and saw Gus shaking his head at a 1/2'' drill ,walked over and asked if I would like to learn drill grinding. After two sessions and dozen attempts,I was pretty good or rather passable. From there, it became my job to grind worn drills. I did not pick web thinning till later life. After trade school,I went on to study Mechanical Engineering and from there did not do any serious machining.