zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

I'm looking at a drawing - at a symbol I've never seen before.

I was top of class in drafting - but that was 40 years ago. (That's right - pre-cad). And...I've only started machining a few months ago...so my knowledge is both old and limited. Okay, I'll say it, near non-existent. (Now show me a schematic and I'll say...yep...that's what it is...a schematic.)

In any case...

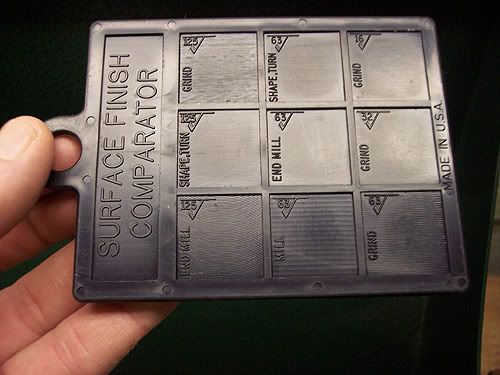

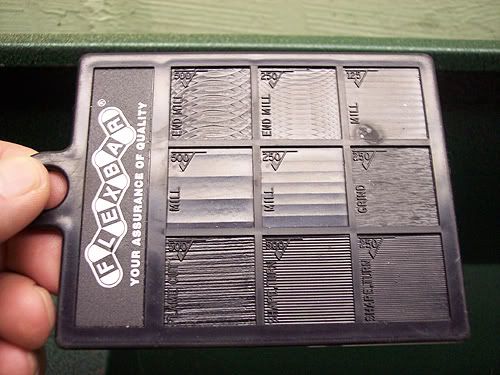

The symbol looks like a large check mark (or V with one leg shorter than the other) with a number inside. One shows 32 and another 64. The part I'm looking at is the crankshaft for a launch engine. (Basically a rod with a disk on one end.) The symbol with the 32 is on the rod while the 64 is on the disk. What do they mean? ??? I'm thinking tolerance but it don't make sense to me.

While I'm here... the diameter of the rod (shaft) is called out as:

.2183 DIA REF. - SLIT FIT

.0005 CLEARANCE WITH DET.

#3.00.040-01 & 3.00.020-01

I'm thinking 'SLIT FIT' should be 'SLIP FIT'?

I get the .2183 (and good luck getting .---3).

And sorry to keep demonstrating my ignorance (maybe I shouldn't have had the wine...but it's Friday night)...I'm now confused about 'REF'. Help. ??? (And don't just tell me 'reference'....and at least one of you won't be able to help themselves. ;D)

0.0003 hahahahahahaha...that's rich...hahahahahaha...like I can do that...hahahaha

I'm happy if there's metal left when I'm done.

Thanks.

No. No machining tonight. Long week. Wine was more medicinal than anything else. (Sure. Sure.)

I was top of class in drafting - but that was 40 years ago. (That's right - pre-cad). And...I've only started machining a few months ago...so my knowledge is both old and limited. Okay, I'll say it, near non-existent. (Now show me a schematic and I'll say...yep...that's what it is...a schematic.)

In any case...

The symbol looks like a large check mark (or V with one leg shorter than the other) with a number inside. One shows 32 and another 64. The part I'm looking at is the crankshaft for a launch engine. (Basically a rod with a disk on one end.) The symbol with the 32 is on the rod while the 64 is on the disk. What do they mean? ??? I'm thinking tolerance but it don't make sense to me.

While I'm here... the diameter of the rod (shaft) is called out as:

.2183 DIA REF. - SLIT FIT

.0005 CLEARANCE WITH DET.

#3.00.040-01 & 3.00.020-01

I'm thinking 'SLIT FIT' should be 'SLIP FIT'?

I get the .2183 (and good luck getting .---3).

And sorry to keep demonstrating my ignorance (maybe I shouldn't have had the wine...but it's Friday night)...I'm now confused about 'REF'. Help. ??? (And don't just tell me 'reference'....and at least one of you won't be able to help themselves. ;D)

0.0003 hahahahahahaha...that's rich...hahahahahaha...like I can do that...hahahaha

I'm happy if there's metal left when I'm done.

Thanks.

No. No machining tonight. Long week. Wine was more medicinal than anything else. (Sure. Sure.)