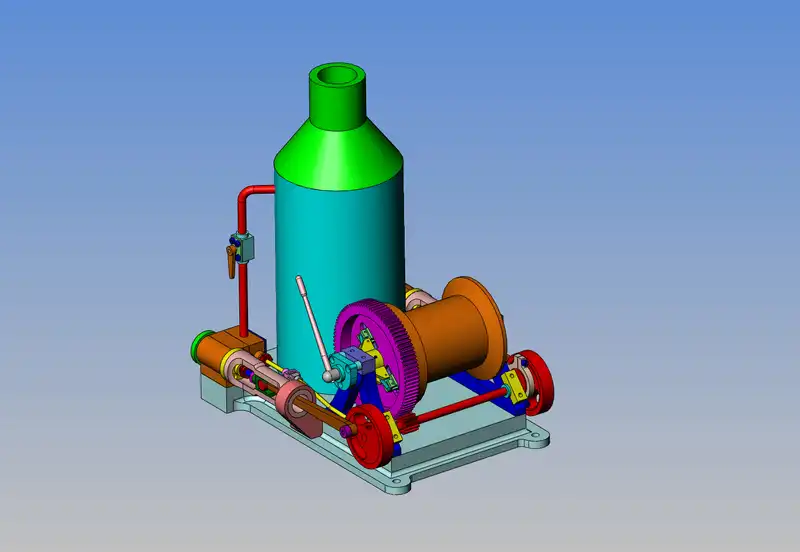

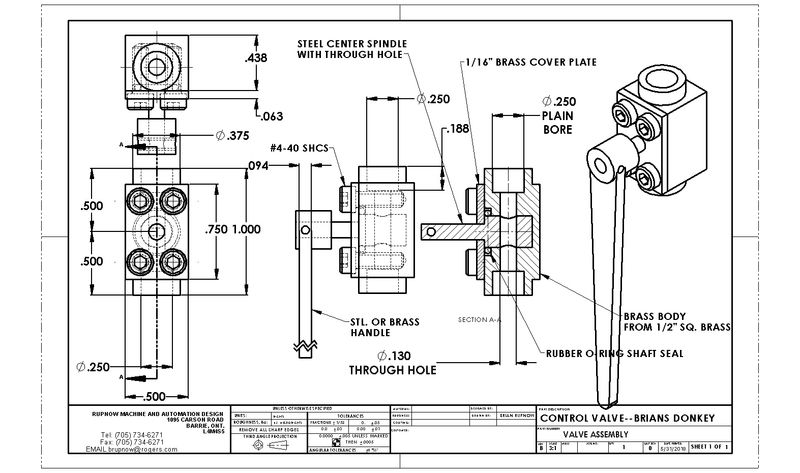

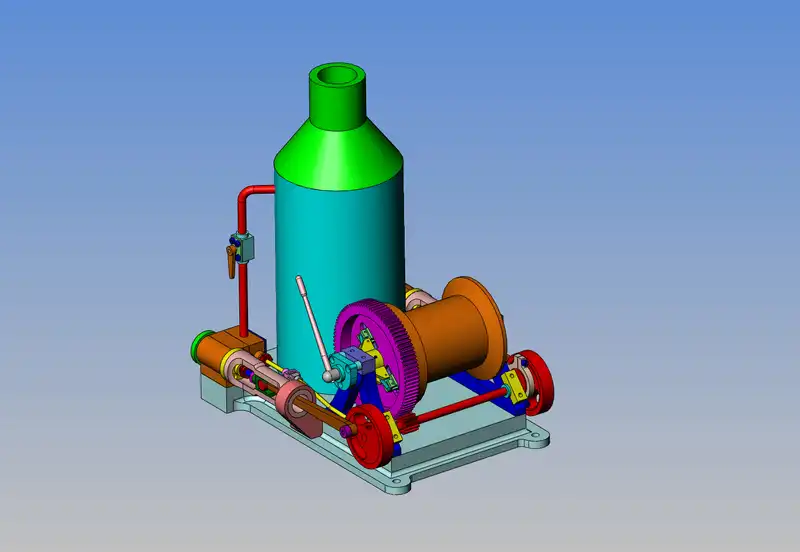

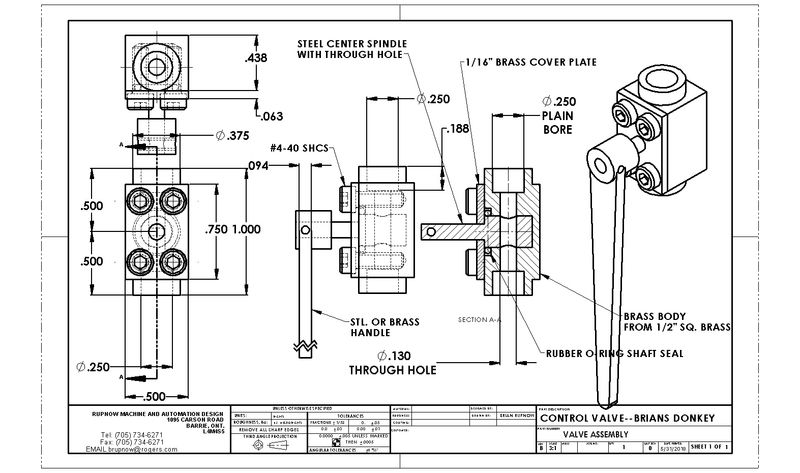

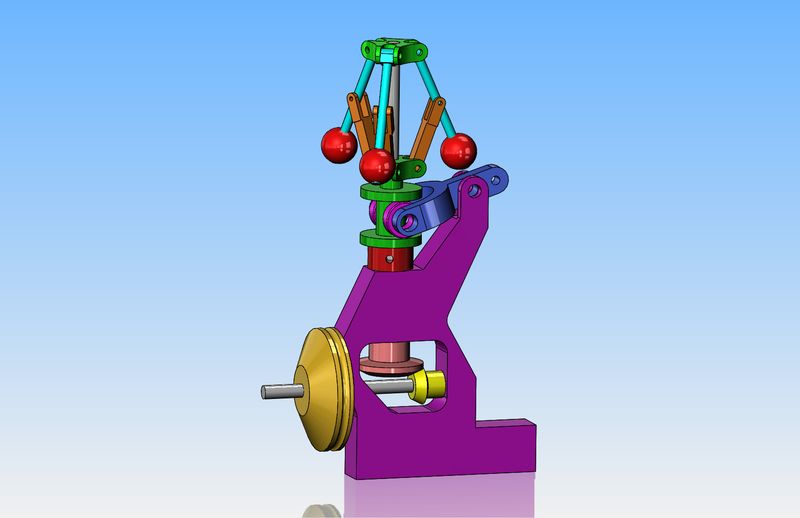

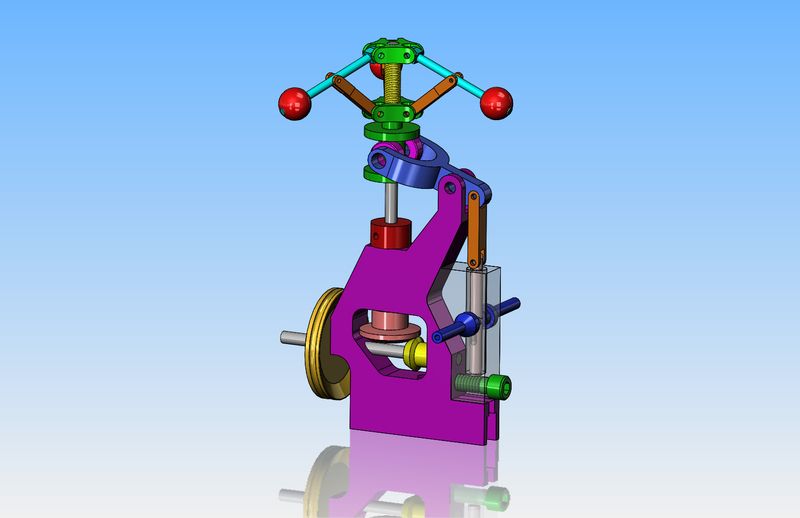

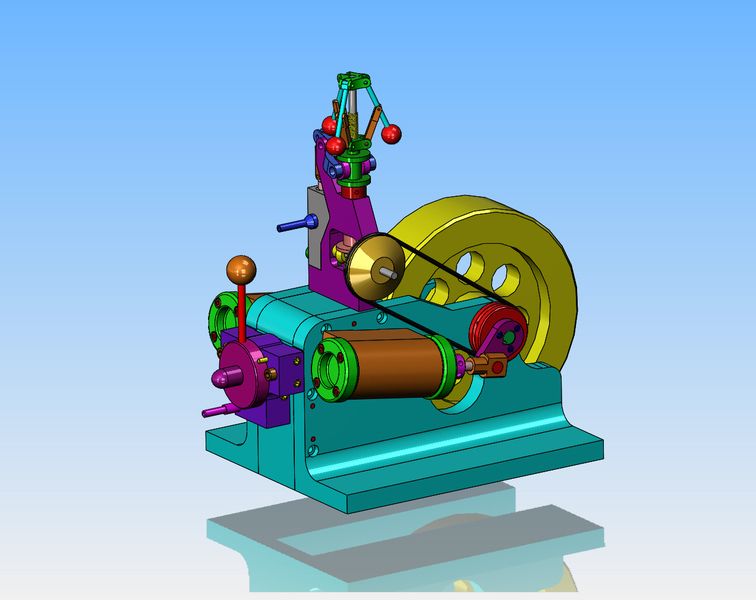

Amvolk--a number of years ago I designed and built a " Steam Donkey Winch" I wanted a valve which would control the speed of the twin "steam engines" so I designed one that worked very well. If you follow the red line coming out of the boiler you will see the valve in place on the line. It worked very well, and gave great control over the engine speed. (And if those twin engines look a bit like a Cretors popcorn Engine" there is a very good reason for that.)