Started this the first part of Dec,2010

I'm now finished with the build so here is some photos of it.

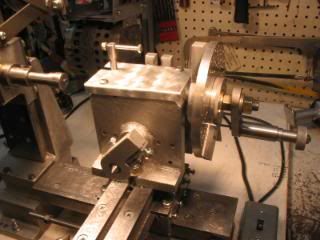

front of dividing head only 3 cast parts make up the body of the frame

back side, with the foot it allows the head to be mounted horizontal and used as a rotary table.

patterns made from pine and mdf or scrap wood

brake is mounted to the frame,it's held on with one 5/16-18 bolt.

I'm now finished with the build so here is some photos of it.

front of dividing head only 3 cast parts make up the body of the frame

back side, with the foot it allows the head to be mounted horizontal and used as a rotary table.

patterns made from pine and mdf or scrap wood

brake is mounted to the frame,it's held on with one 5/16-18 bolt.