Hi All,

I need to build a simple differential for my traction engine. I am looking for something dead simple and easy to build. It needs to fit hopefully in the middle of my rear axle. The axle is solid at present but will bu cut to suit. One and of the axle is chain driven from the gears and needs to drive the diff to drive the other wheel. The axle is at the moment about 12mm dia and the length available is around 125mm.

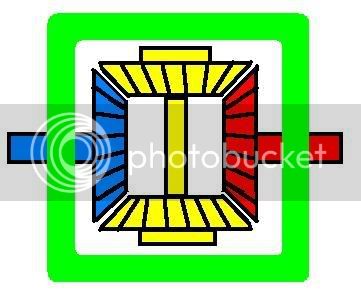

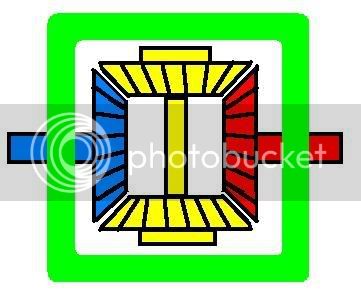

One thought I had wasthe pic below. The red gear driven from one side of the axle drives the blue gear via the yellow set. The yellow ones are held together by a rod with a nut on each end. This allows them to be preloaded but to still turn independently. The strain of the wheels reacting to steering should allow them to roll around thus reducing the drive to the other wheel. All enclosed in the green case. Simple but may work.

Any ideas, views or suggestions please.

Julian.

I need to build a simple differential for my traction engine. I am looking for something dead simple and easy to build. It needs to fit hopefully in the middle of my rear axle. The axle is solid at present but will bu cut to suit. One and of the axle is chain driven from the gears and needs to drive the diff to drive the other wheel. The axle is at the moment about 12mm dia and the length available is around 125mm.

One thought I had wasthe pic below. The red gear driven from one side of the axle drives the blue gear via the yellow set. The yellow ones are held together by a rod with a nut on each end. This allows them to be preloaded but to still turn independently. The strain of the wheels reacting to steering should allow them to roll around thus reducing the drive to the other wheel. All enclosed in the green case. Simple but may work.

Any ideas, views or suggestions please.

Julian.