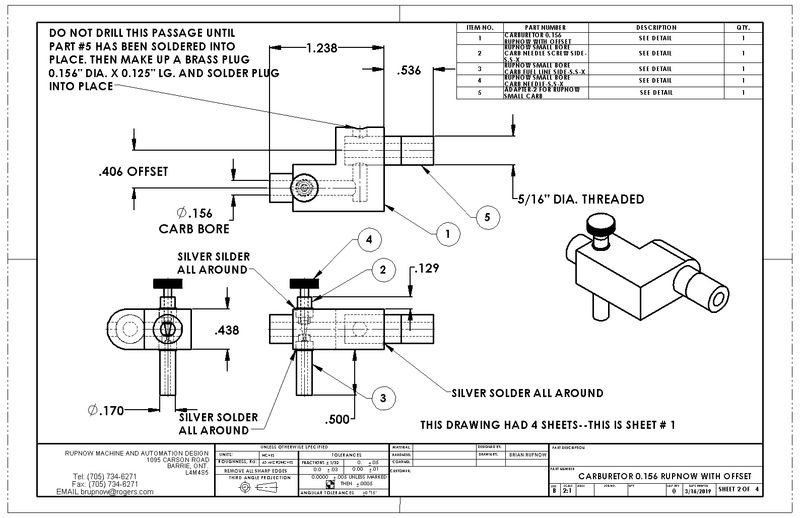

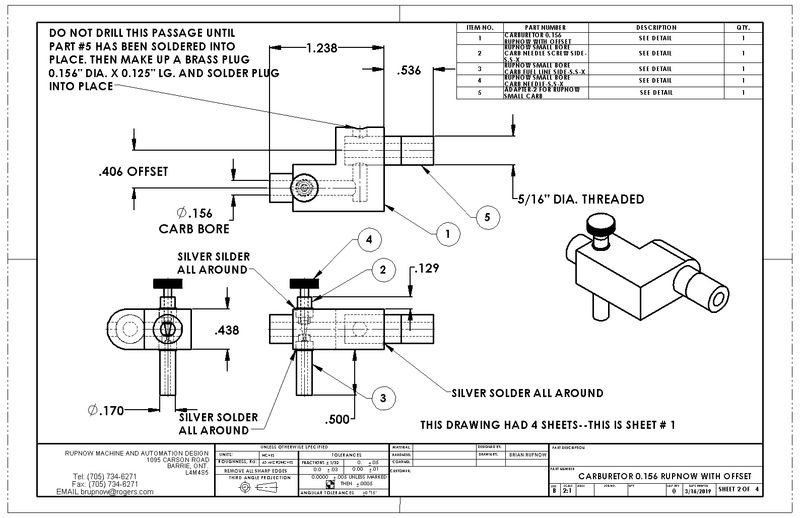

As promised, here is the new carburetor drawing. It actually has a total of four sheets to it. I am posting an image of the first page here. The full four pages can be downloaded from the attached link.---Brian

http://www.mediafire.com/file/7b03o2fo3b9bfns/CARBURETOR_0.156_RUPNOW_WITH_OFFSET.JPG/file

http://www.mediafire.com/file/7b03o2fo3b9bfns/CARBURETOR_0.156_RUPNOW_WITH_OFFSET.JPG/file