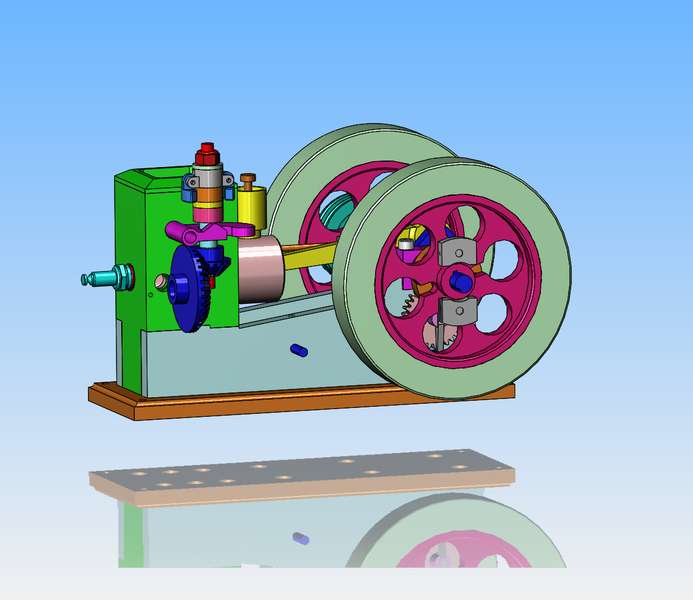

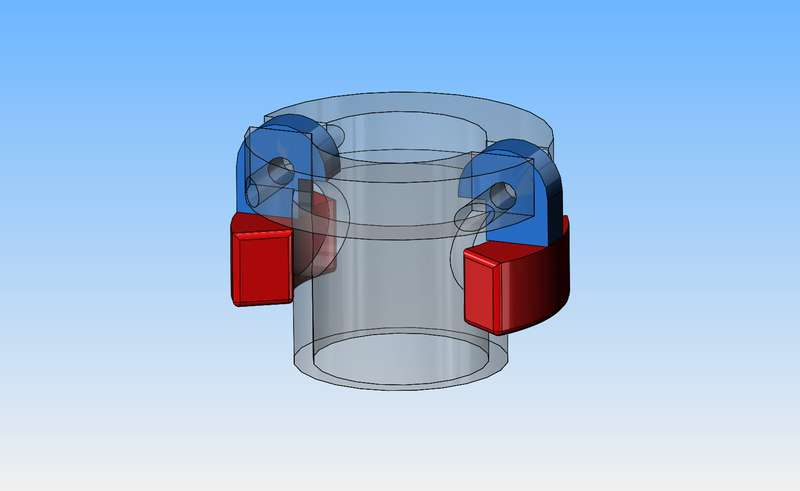

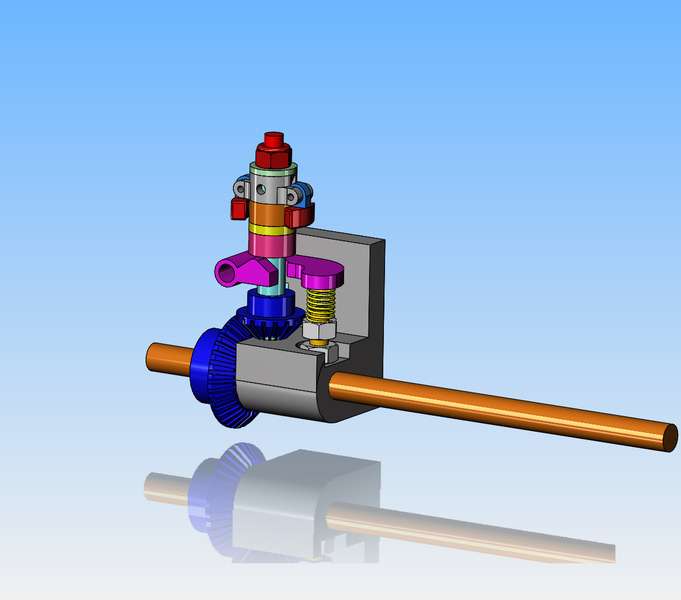

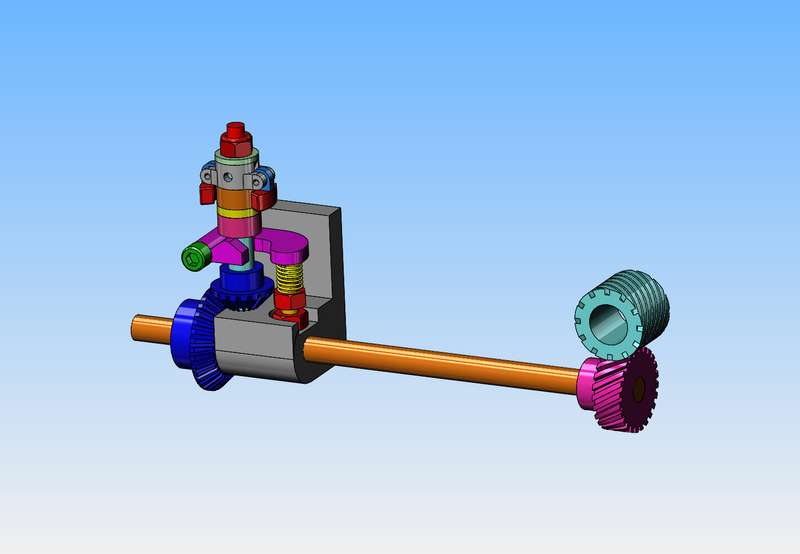

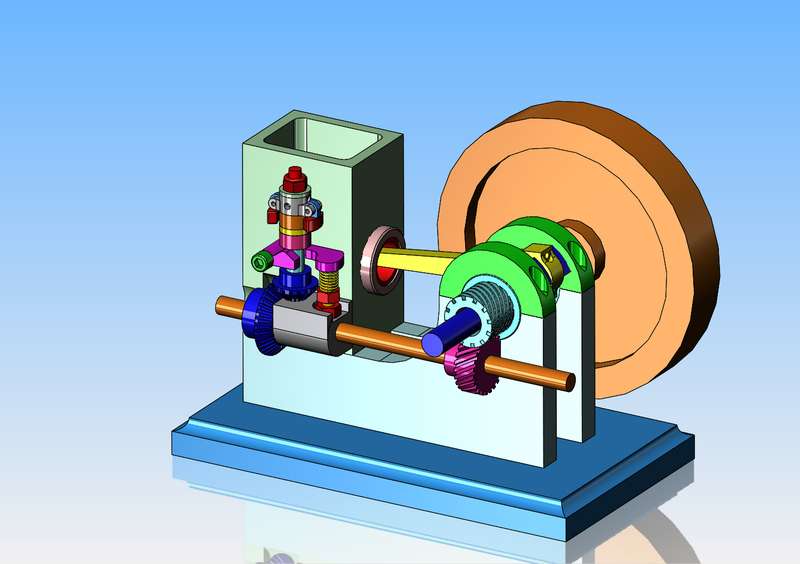

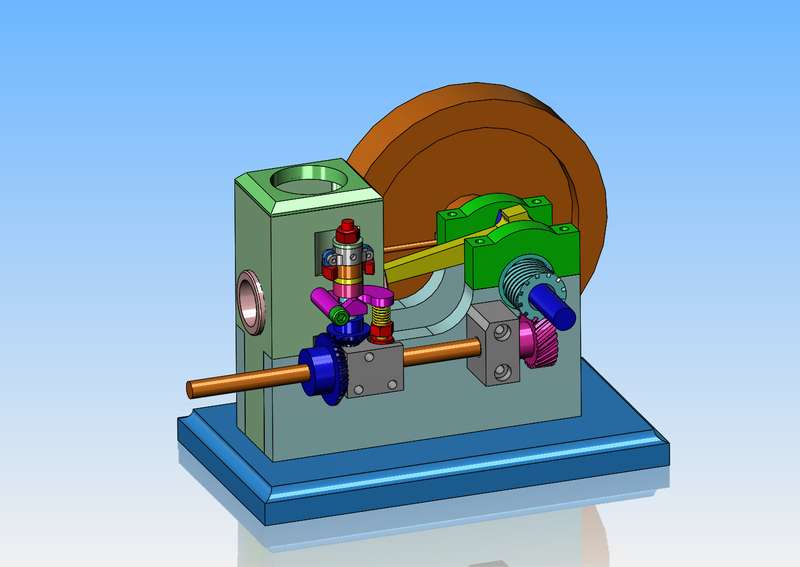

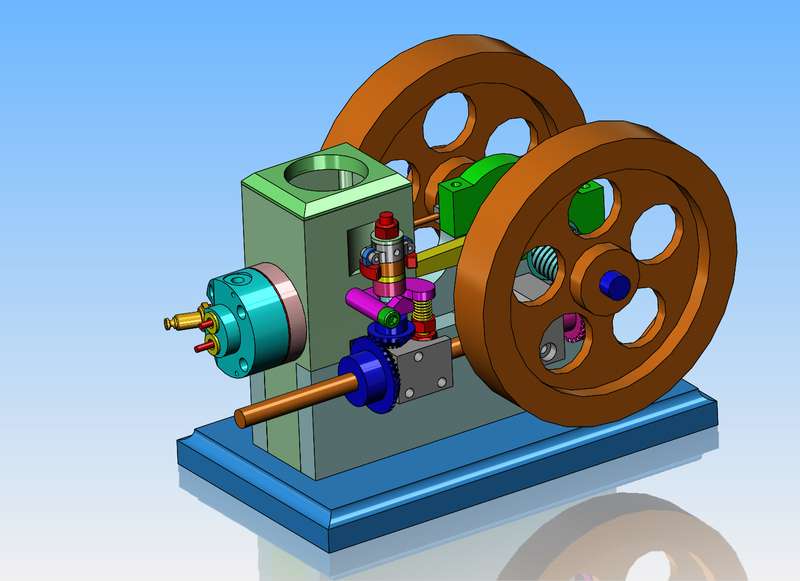

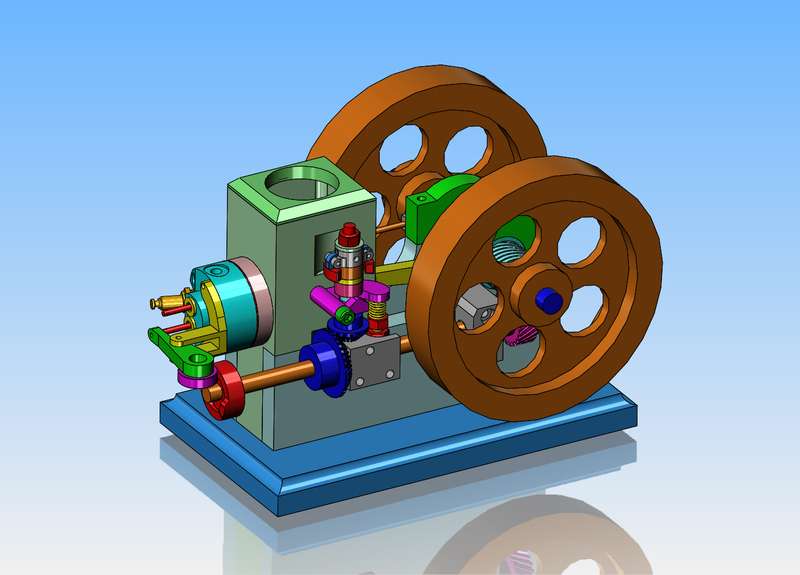

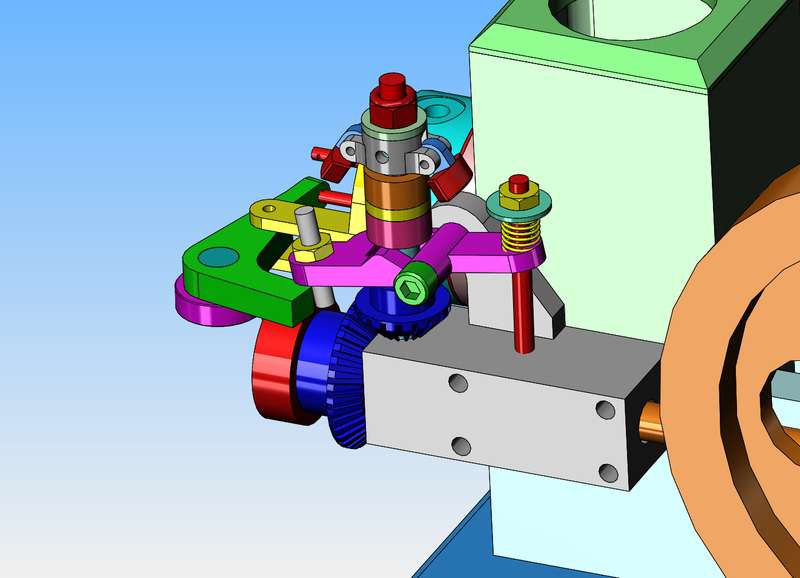

Brian - As you're a fan of unusual mechanical designs I thought I'd mention something I came across today that I've never seen, possibly so you can file it away in the memory banks for future usage if you desire. Basically, it was a 'normal' horizontal engine, with a normally operated exhaust valve. However, instead of an atmospheric intake valve, it was cam actuated. All pretty standard stuff, except the same 'pushrod' operated both intake and exhaust valves. The exhaust used a rocker arm but the pushrod had another arm attached to it and simply pulled down on the intake to activate it. I couldn't see it but the cam must have had both a peak for the exhaust and a 'valley' for the intake, along with a central nominal diameter. Plus the pushrod (push-pull rod?) had to have some sort of spring keeping it in contact with the cam and strong enough to overcome the intake spring force. It's not an engine I can see running currently but I imagine it's an interesting motion that would scale fairly easily.