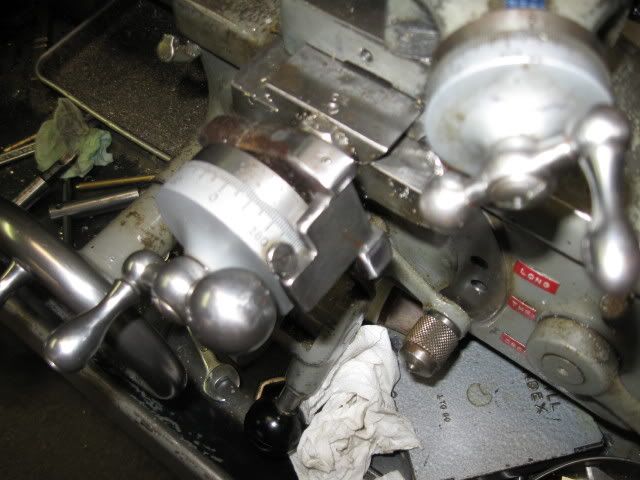

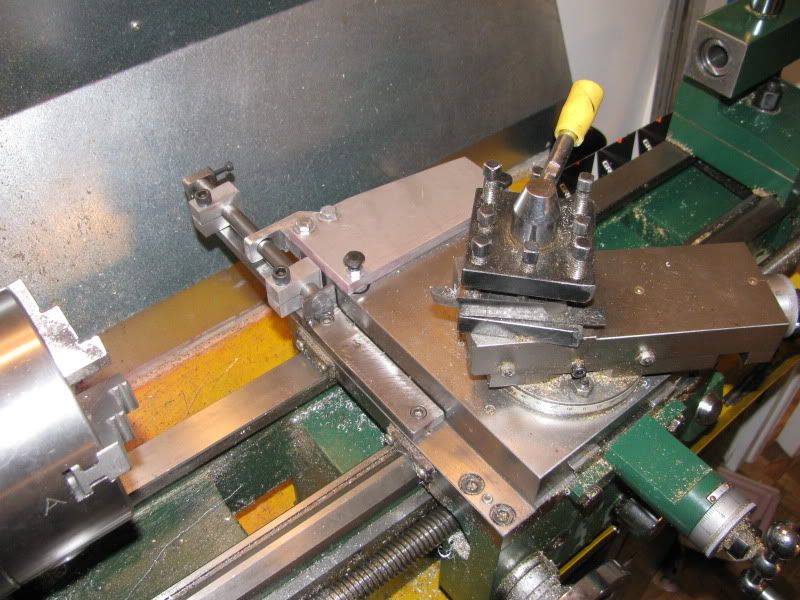

Back when I got my 10 x 18 Busy Bee lathe about 2 years ago, one of the first things I built was a carriage stop which I could clamp to the ways of the lathe. Since I don't use the power feed feature on my lathe, I have found the carriage stop to be very valuable when turning to a shoulder and similar operations. I even built a second one to use on the tailstock side of the carriage.

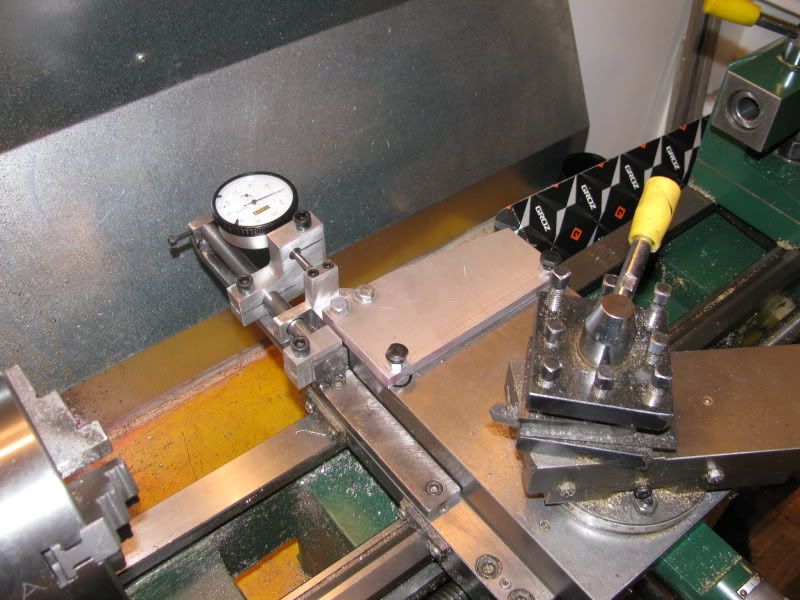

Now I am wondering about building something similar to be used as a cross feed stop, which would be a big help when turning to a specific diameter.

I did a search and couldn't find one on this forum, and yet I am sure someone has built one before.---They just make so much sense that I am sure I'm not the first person to think of this.

Does anyone know of a post covering this issue?

Thanks---Brian

Now I am wondering about building something similar to be used as a cross feed stop, which would be a big help when turning to a specific diameter.

I did a search and couldn't find one on this forum, and yet I am sure someone has built one before.---They just make so much sense that I am sure I'm not the first person to think of this.

Does anyone know of a post covering this issue?

Thanks---Brian