Here is a machine-shop way to balance a single cylinder engine:

Weigh the small end of the connecting rod, and record this value as reciprocating mass.

Weigh the large end of the connecting rod, and record this value as rotating mass.

Note: the small-end rod weight, plus the big-end rod weight, should equal the total weight of the rod. If it doesnt, retake the measurements, as you did something wrong.

Add up the weights of all pure reciprocating components (i.e. the small-end of connecting rod, the piston, rings, wrist-pin, etc). Divide this number by two.

Take the above number (which is equal to half of all reciprocating mass), and add it to the weight of the large-end of the connecting rod (the rotating mass). This number is the final equivalent mass that must be balanced out by the crankshaft.

Machine a cylinder on the lathe that weighs the same as your equivalent mass, as calculated above. Be sure to include a small eye bolt for attaching string, or dental floss.

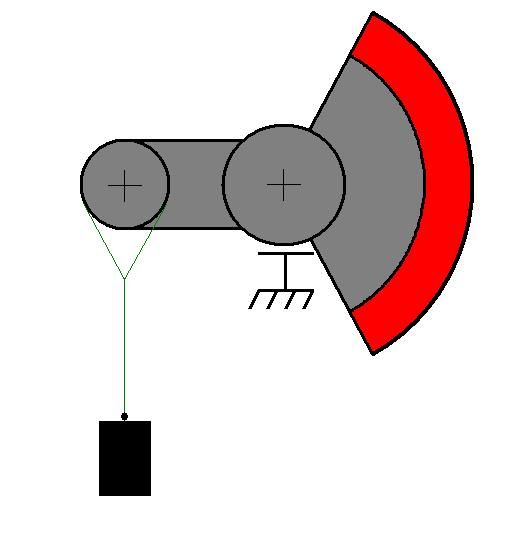

Manufacture your crankshaft with oversized counterweights (because its easier to remove metal than it is to add it). Suspend the crankshaft on a set of machined parallels. Ensure the parallels are perfectly level and free of debris as the crank must be able to roll freely with the smallest of effort.

Attach the equivalent mass to the crankshafts connecting rod journal with some small string, or dental floss. The rod journals line of action must be parallel to the supports, and perpendicular to the string (as shown). The string must be perfectly in-line with the center-axis of the rod journal. If the string is off-center, is will introduce significant error.

If the crankshaft rotates clockwise, machine away material from the red area of the crank, until there is no rotation.

If the crankshaft rotates counterclockwise, you need to add material to the red area of the crank, until there is no rotation.

Remember that a very small rotation is still a rotation.

The engine is balanced when there is no crankshaft rotation. When you get close, you can drill holes in the counterweights to sneak up on the final mass, in lieu of lathe operations where you can overshoot.

This method will provide more than adequate results, and permit you to run a neutrally balanced flywheel - - - in a single cylinder engine. . . .