kellswaterri

Senior Member

- Joined

- Oct 14, 2007

- Messages

- 117

- Reaction score

- 6

Hello all,

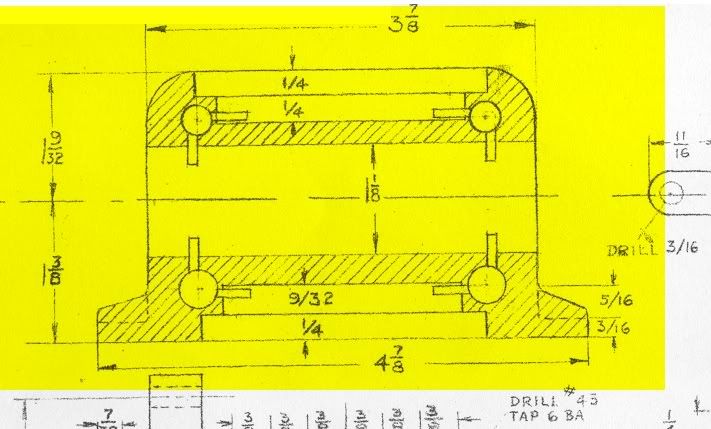

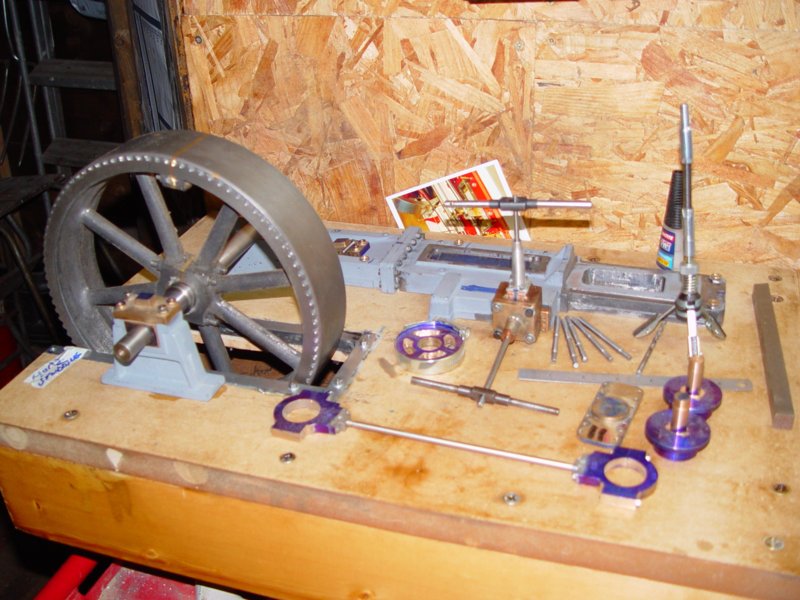

this is the Corliss cylinder that I will soon be starting on machining...

I need to machine and place porting slots as shown on the drawing...could I have your collective wisdom on the approach to this one Please.

All the best for now,

John.

http://i22.photobucket.com/albums/b329/corncrake/

seems to be the only way I can get this up on the web at the moment... the highlighted drawing is the cylinder in question...

this is the Corliss cylinder that I will soon be starting on machining...

I need to machine and place porting slots as shown on the drawing...could I have your collective wisdom on the approach to this one Please.

All the best for now,

John.

http://i22.photobucket.com/albums/b329/corncrake/

seems to be the only way I can get this up on the web at the moment... the highlighted drawing is the cylinder in question...