You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

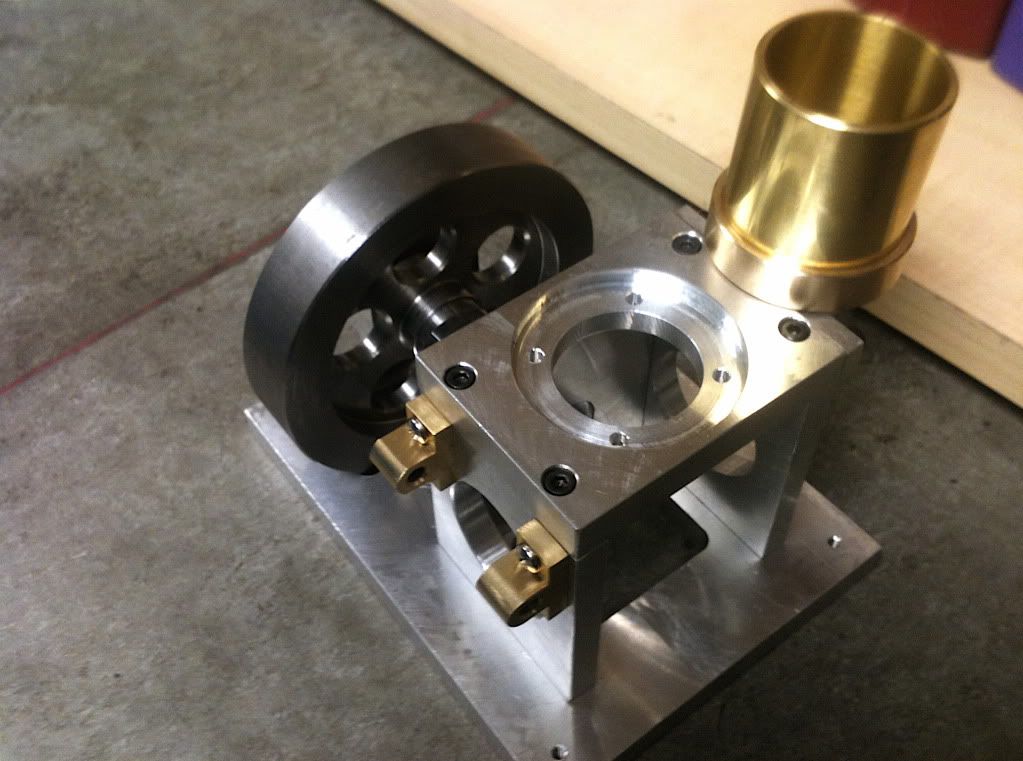

Coming along nicely

- Thread starter Fingers

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

That's looking good! Finish it! Finish it! ;D

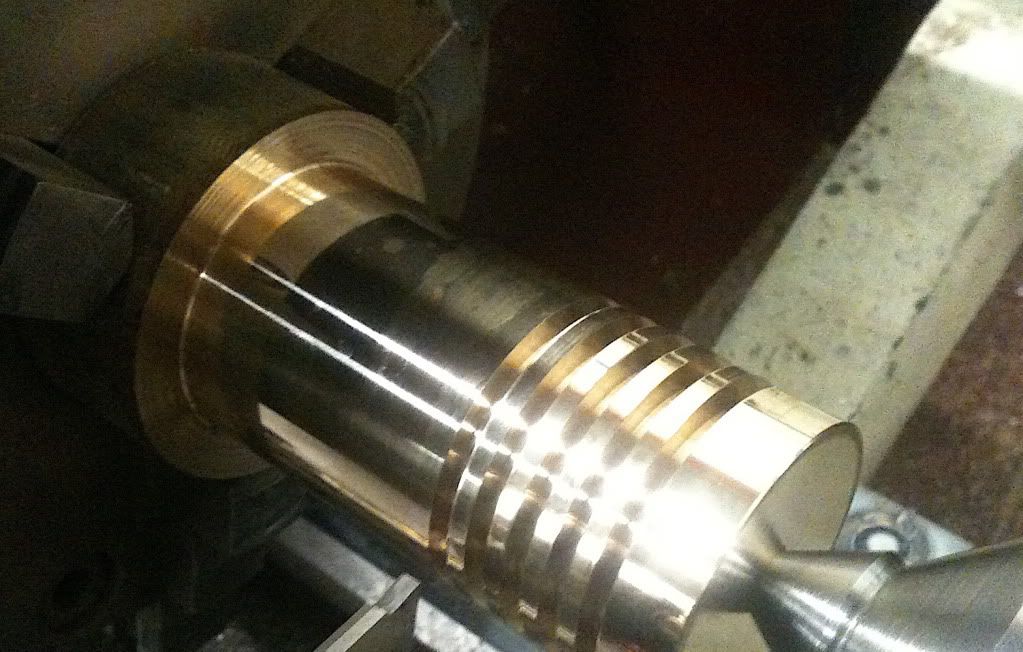

Thanks everyone for your kind comments, the cylinder is 79mm with a 24mm x 36mm piston and a stroke of 40mm. I finished assembling all my parts Just need to a few more pieces, the springs being my downfall as I cannot get any spring steel handy, I wonder if I could use a 1/16 welding rod it's just a straight spring with one loop ?

Thanks pat il have to keep scavenging something will turn up, il let ye know what I find. Will try and get some more done today fingers crossed. Il have some new pictures aswel if you do decide to make it omnimill any questions I can help you with just ask .

Regards j

Regards j

- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

Lovely work, Fingers. From your descripton, it sounds like the engine spins over freely enough. Of course, the next question is, how is the fit between the piston and the cylinder? I wouldn't worry about balancing the flywheel at this point. These engines don't typically turn over fast enough for vibration to be a problem.

Chuck

Chuck

Thanks chuck

Well if I cover the slot in the cylinder with my tumb it won't turn over even with plenty force so I'm pretty confident the fit is good, at least untill the brass wears out. If I get it to run I will strip it all down and champher all my edges and a good polish, I was even picking some timber for a base today I got a slice of rose wood about 1" thick with bark still on I'm thinking of varnishing it all up for a base, or should I just put it on some plained teak ?

Regards j

Please bear in mind i only cut it with chainsaw today so it will look better when thinned and sanded, or is it silly.

Well if I cover the slot in the cylinder with my tumb it won't turn over even with plenty force so I'm pretty confident the fit is good, at least untill the brass wears out. If I get it to run I will strip it all down and champher all my edges and a good polish, I was even picking some timber for a base today I got a slice of rose wood about 1" thick with bark still on I'm thinking of varnishing it all up for a base, or should I just put it on some plained teak ?

Regards j

Please bear in mind i only cut it with chainsaw today so it will look better when thinned and sanded, or is it silly.

Similar threads

- Replies

- 13

- Views

- 1K

- Replies

- 13

- Views

- 624

- Replies

- 22

- Views

- 961