Tony Bird

Senior Member

Hi Chuck,

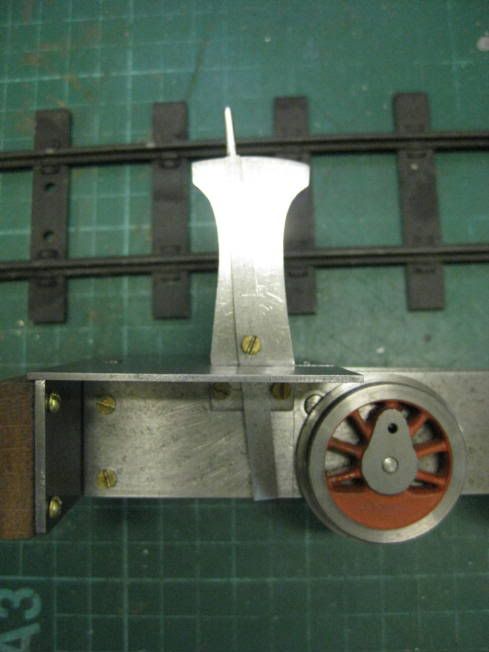

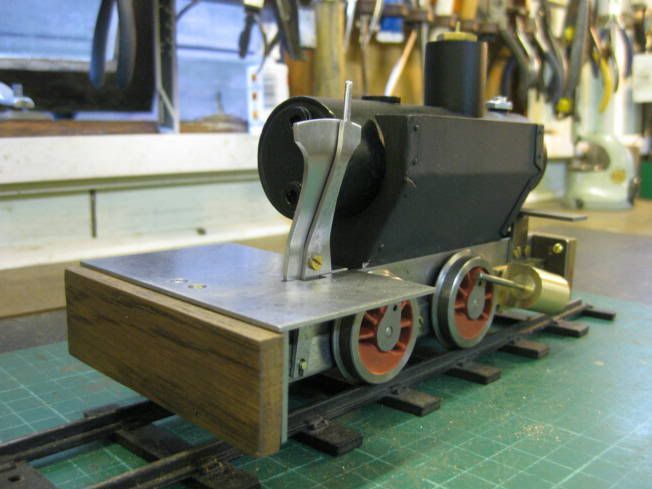

La Belle 'Anne' is gauge '0', 32mm or 1.1/4" which is the gauge of my layout and garden railway, it is also the most complete of Colin's drawings. La Belle 'Barbara' is the inside frame G1 version, it's overall length and height is the same as the other two versions but its an 1/2" wider to accommodate the larger gauge.

Regards Tony.

La Belle 'Anne' is gauge '0', 32mm or 1.1/4" which is the gauge of my layout and garden railway, it is also the most complete of Colin's drawings. La Belle 'Barbara' is the inside frame G1 version, it's overall length and height is the same as the other two versions but its an 1/2" wider to accommodate the larger gauge.

Regards Tony.