Hi Guys

Another piece of work from my shop (which is not yet completed):

I am really fascinated by a type of boiler called "Cochran Boiler":

And i one day decided to build my own:

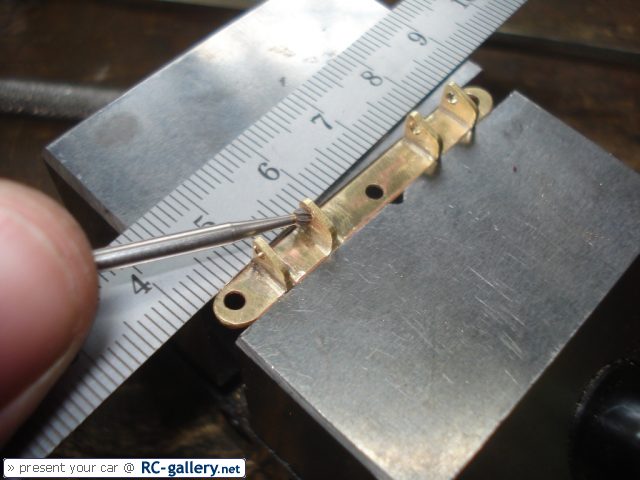

First parts are being tempered:

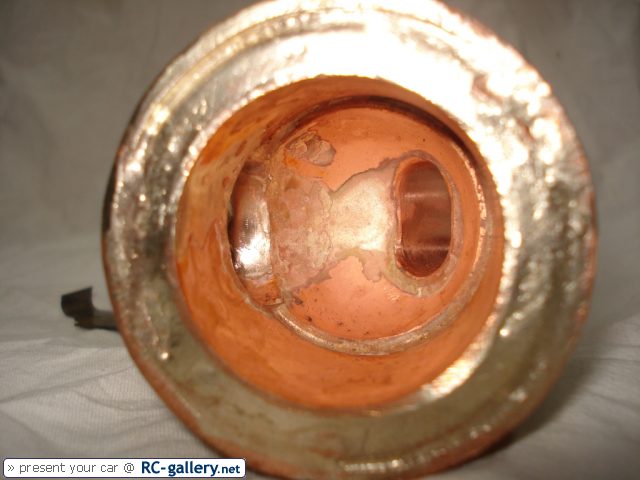

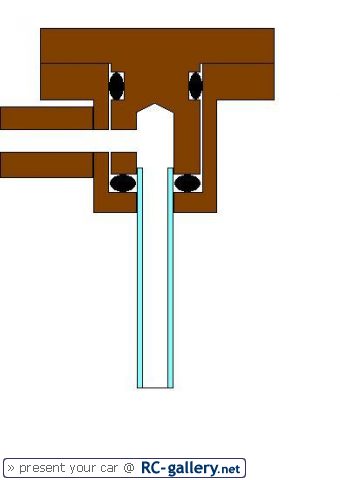

I used a round piece of pearwood to make the form for driving: (They were just felling a pear when i started my project and i took a piece of it. I then turned it down to the required diameter.)

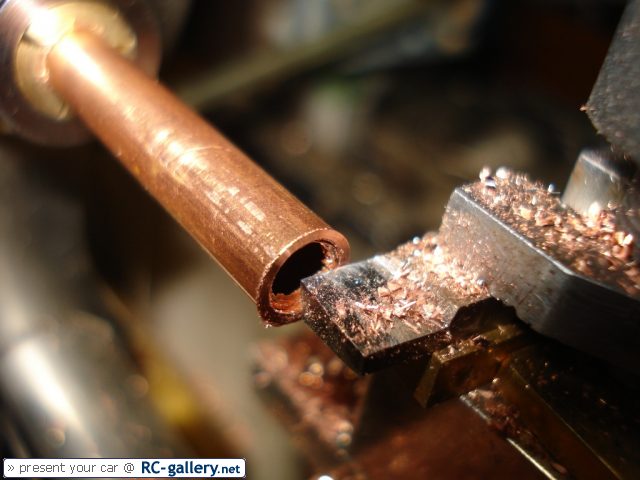

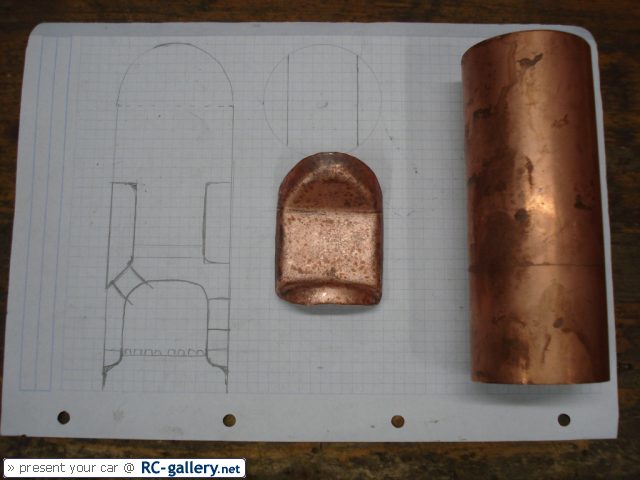

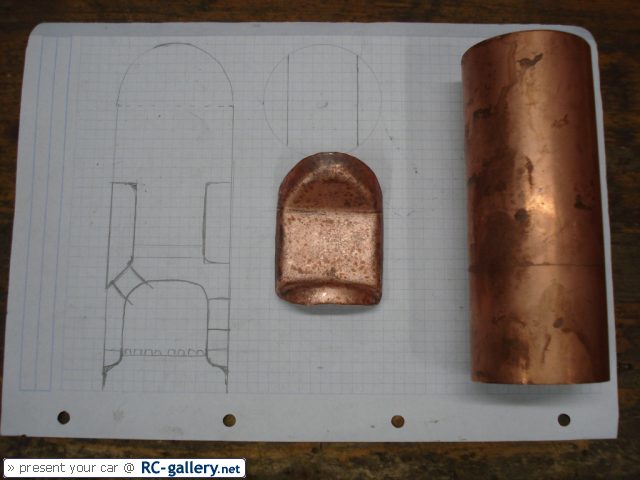

That's the tube and also the first smoketube holding shell

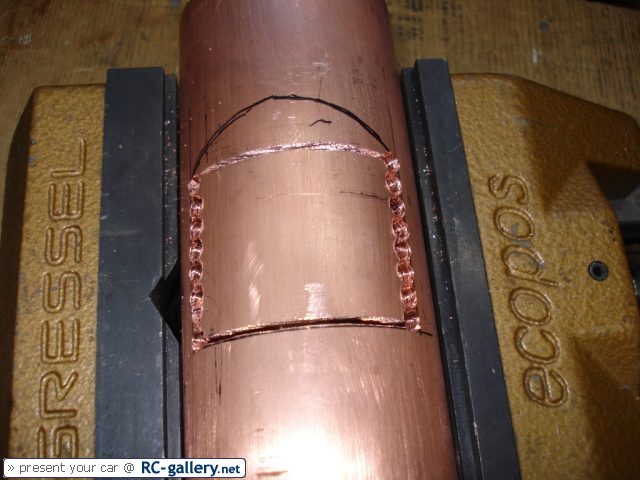

And the second shell for the side of the chimney is just being driven:

tempering it with my torch:

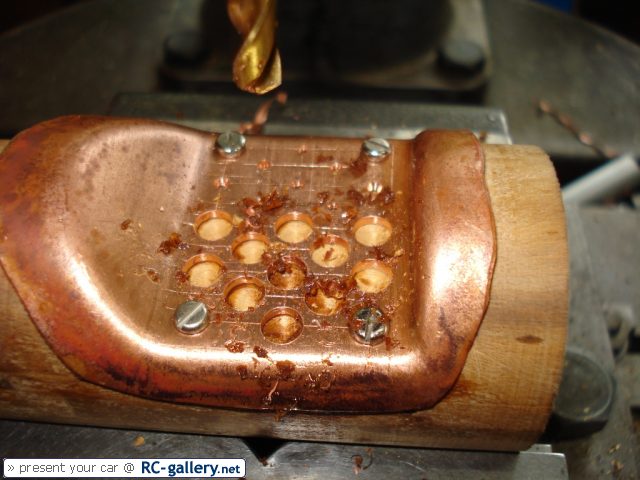

Are there enough tubes, or shall i make some more...?

[continues soon]

Another piece of work from my shop (which is not yet completed):

I am really fascinated by a type of boiler called "Cochran Boiler":

And i one day decided to build my own:

First parts are being tempered:

I used a round piece of pearwood to make the form for driving: (They were just felling a pear when i started my project and i took a piece of it. I then turned it down to the required diameter.)

That's the tube and also the first smoketube holding shell

And the second shell for the side of the chimney is just being driven:

tempering it with my torch:

Are there enough tubes, or shall i make some more...?

[continues soon]