vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

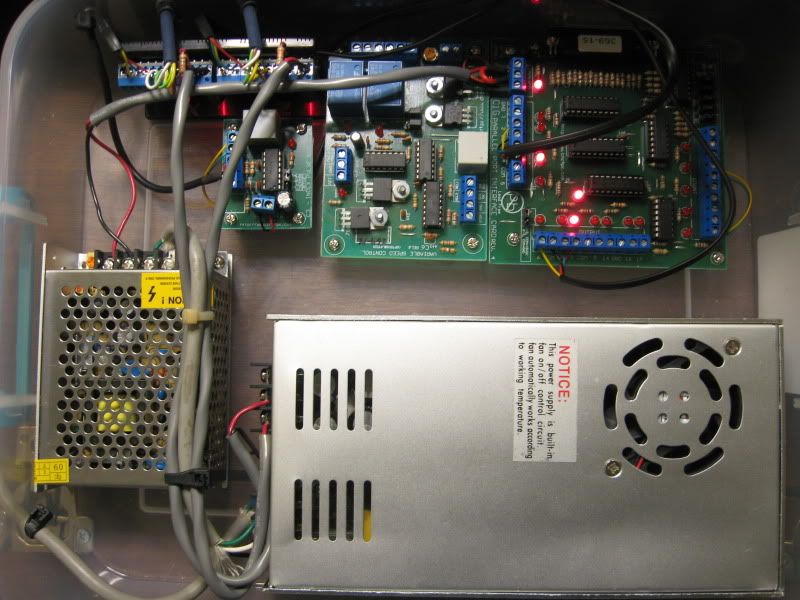

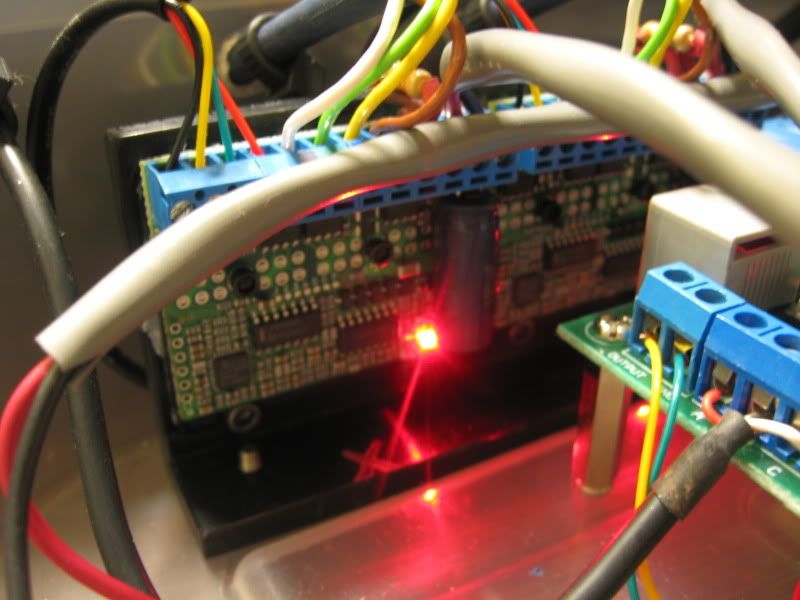

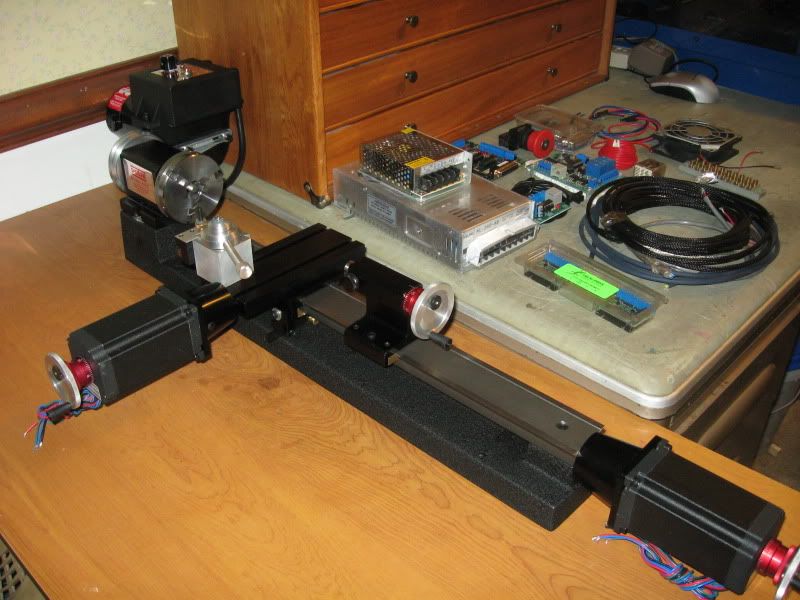

Well, I've finally managed to get a lathe at home!

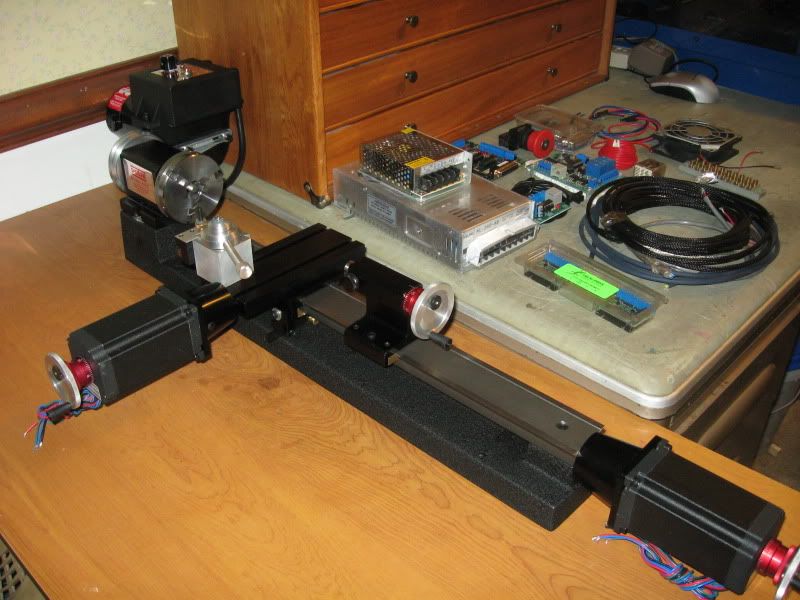

To compliment my little Sherline mill, I've paired it with a Sherline lathe, which I'll be converting to a CNC machine.

For now, it's a basic "CNC Ready" lathe (thrust bearings on the leadscrews, and motor mounts already fitted from the factory), a pair of stepper motors, and a pile of goodies.

To compliment my little Sherline mill, I've paired it with a Sherline lathe, which I'll be converting to a CNC machine.

For now, it's a basic "CNC Ready" lathe (thrust bearings on the leadscrews, and motor mounts already fitted from the factory), a pair of stepper motors, and a pile of goodies.