- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

I started a class on CNC lathe g-code programming last night. It's a once a week evening class that goes on for 3 hours or so. If anyone is interested I can "blog" the weekly progress.

In any case, the textbook used is Introduction to Computer Numerical Control by Valentino and Goldberg. I just found and ordered a used copy at www.alibris.com. The course can be passed without using the textbook as the school has online exercises and projects for each week, plus the lecture. We are then given a homework program to write for the next week's class.

The book comes with a couple of software programs that are crucial, and could be useful for anyone here. One is a g-code editor that does syntax coloring and line numbering. The other is a simulator named Virtual CNC. Using this program, we defined a "job" that specifies the machine, stock to be turned, tools to be used, and the g-code program to emulate. You can then run the job and view the completed part in either 3D or cross section. The program is a "demo" version for students and limited to 150 line programs.

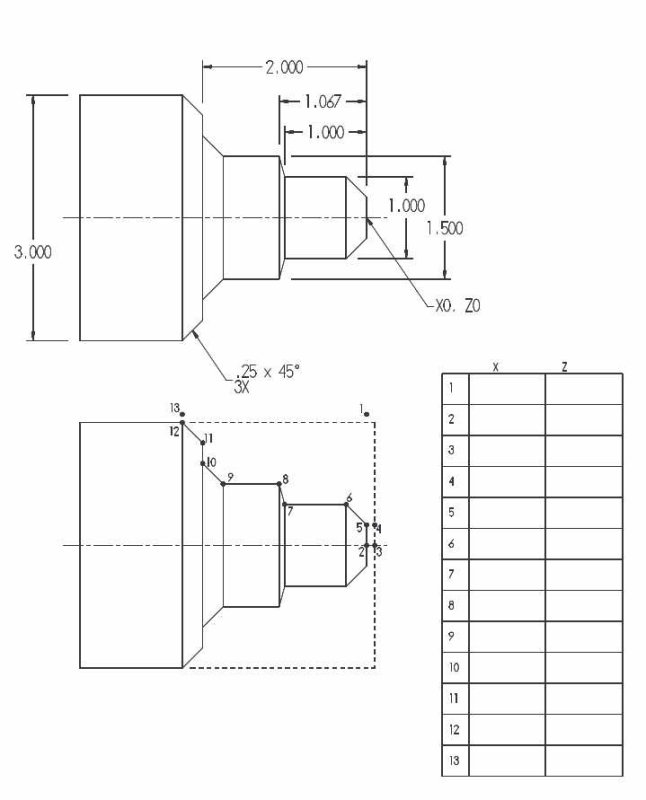

The first exercise was a simple program that just does facing and an external contour. For next week's class I need to program a part with external turning and internal drilling and boring.

In any case, the textbook used is Introduction to Computer Numerical Control by Valentino and Goldberg. I just found and ordered a used copy at www.alibris.com. The course can be passed without using the textbook as the school has online exercises and projects for each week, plus the lecture. We are then given a homework program to write for the next week's class.

The book comes with a couple of software programs that are crucial, and could be useful for anyone here. One is a g-code editor that does syntax coloring and line numbering. The other is a simulator named Virtual CNC. Using this program, we defined a "job" that specifies the machine, stock to be turned, tools to be used, and the g-code program to emulate. You can then run the job and view the completed part in either 3D or cross section. The program is a "demo" version for students and limited to 150 line programs.

The first exercise was a simple program that just does facing and an external contour. For next week's class I need to program a part with external turning and internal drilling and boring.