trumpy81

Member

- Joined

- Oct 31, 2010

- Messages

- 219

- Reaction score

- 52

Coilmotorworks---I don't have too many old "Rumley Oil Pulls" (whatever that is) laying around my garage. However, I do react well to good clear sketches, explaining what you are suggesting.----Brian

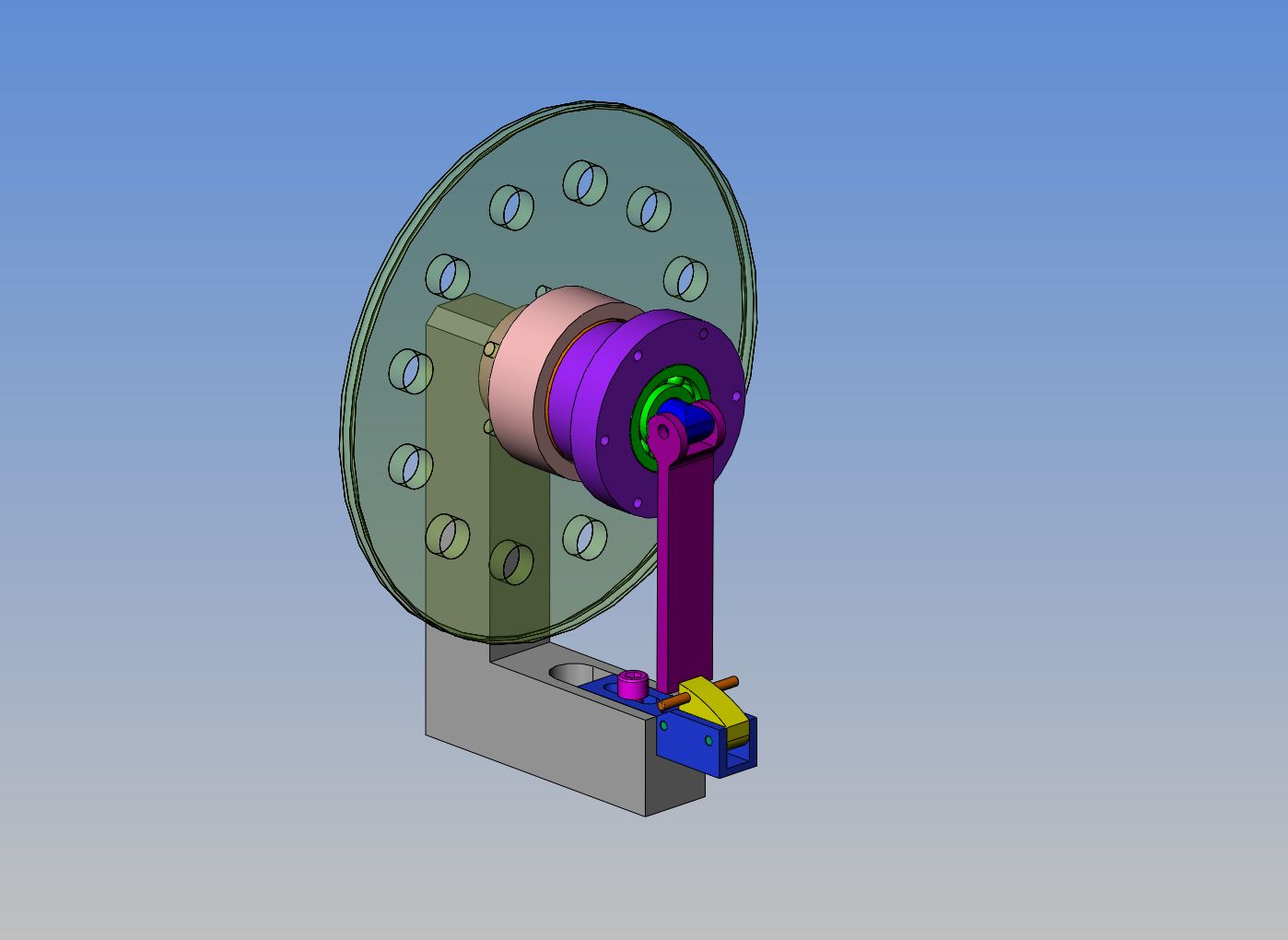

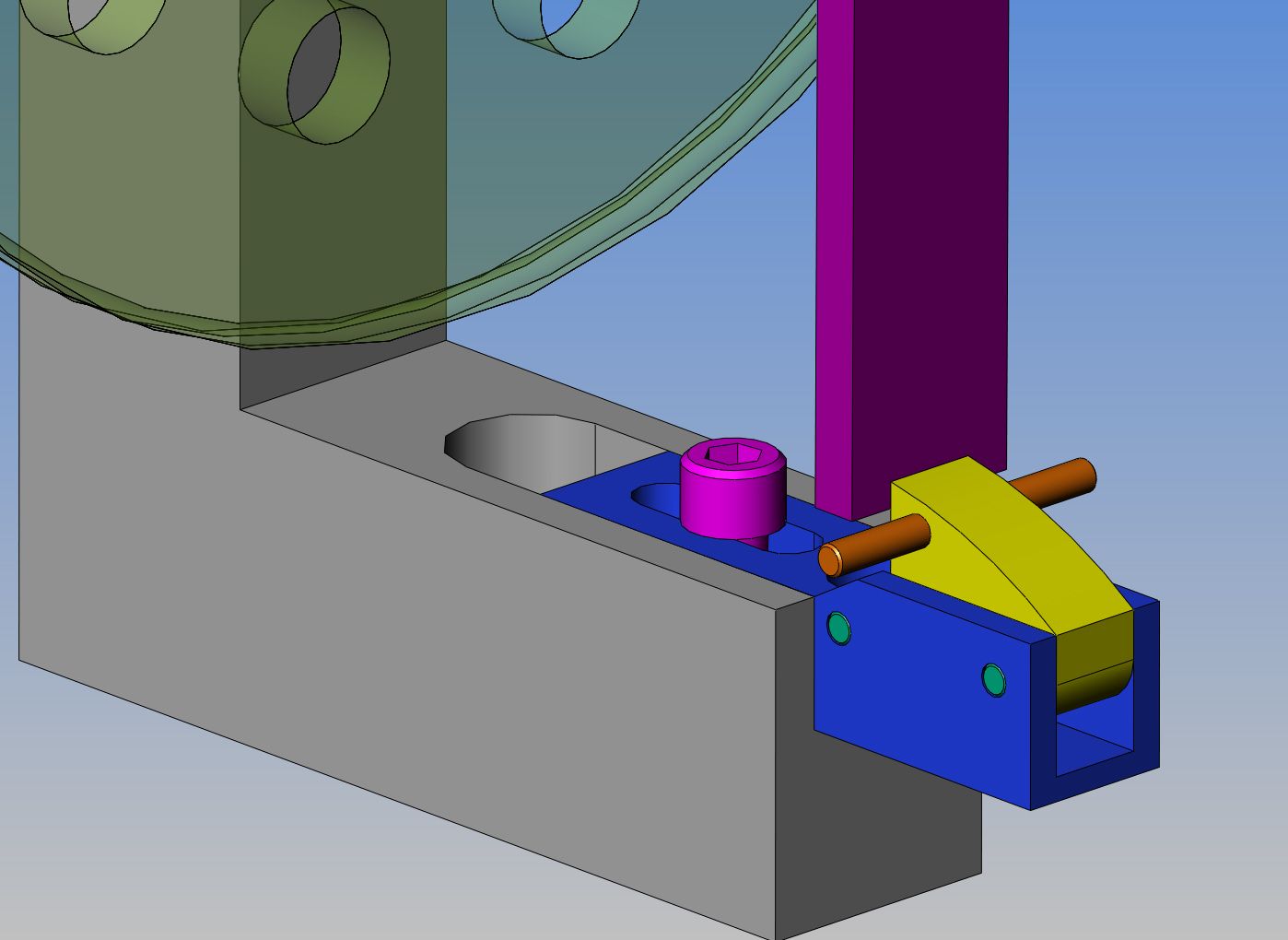

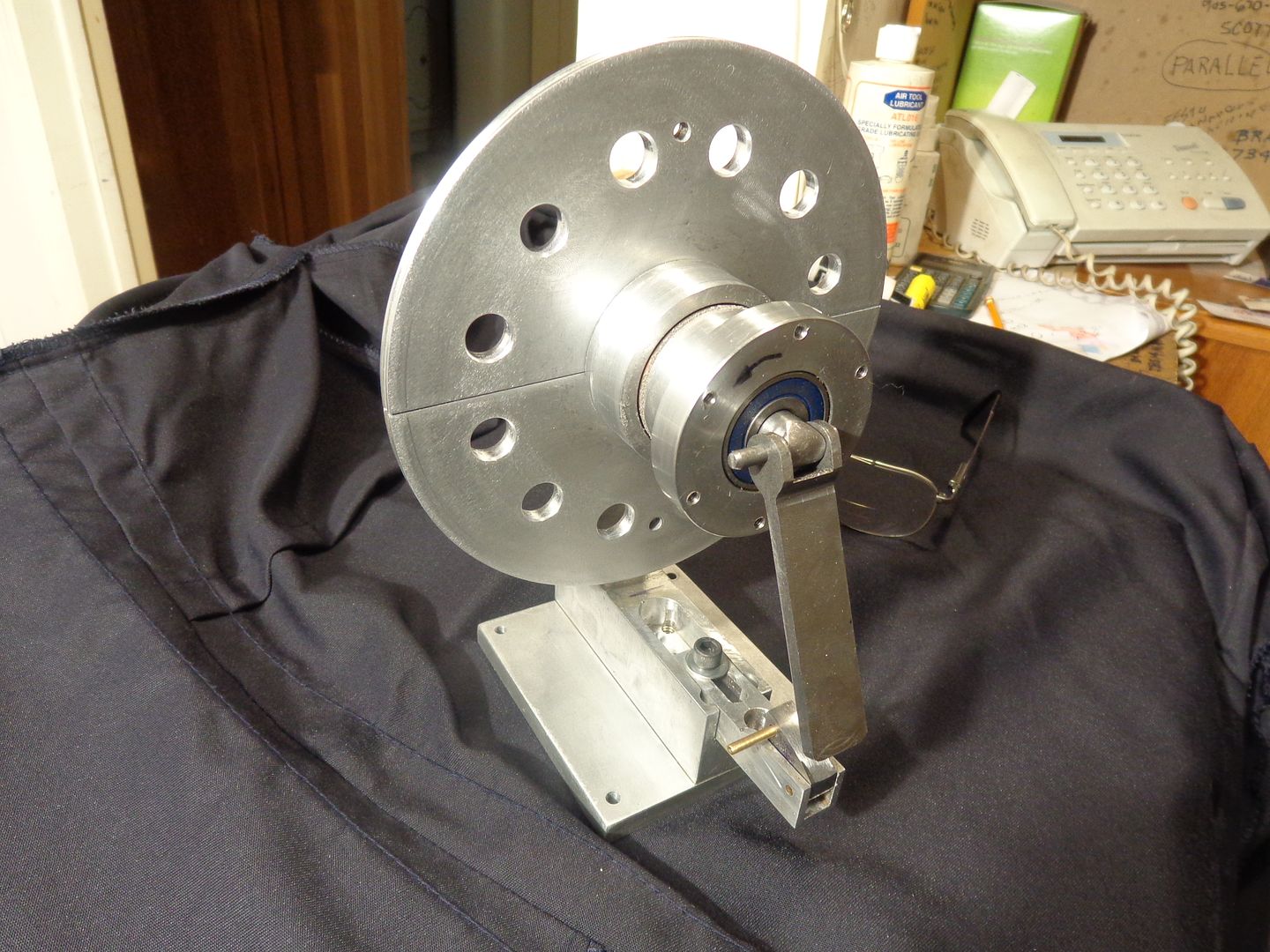

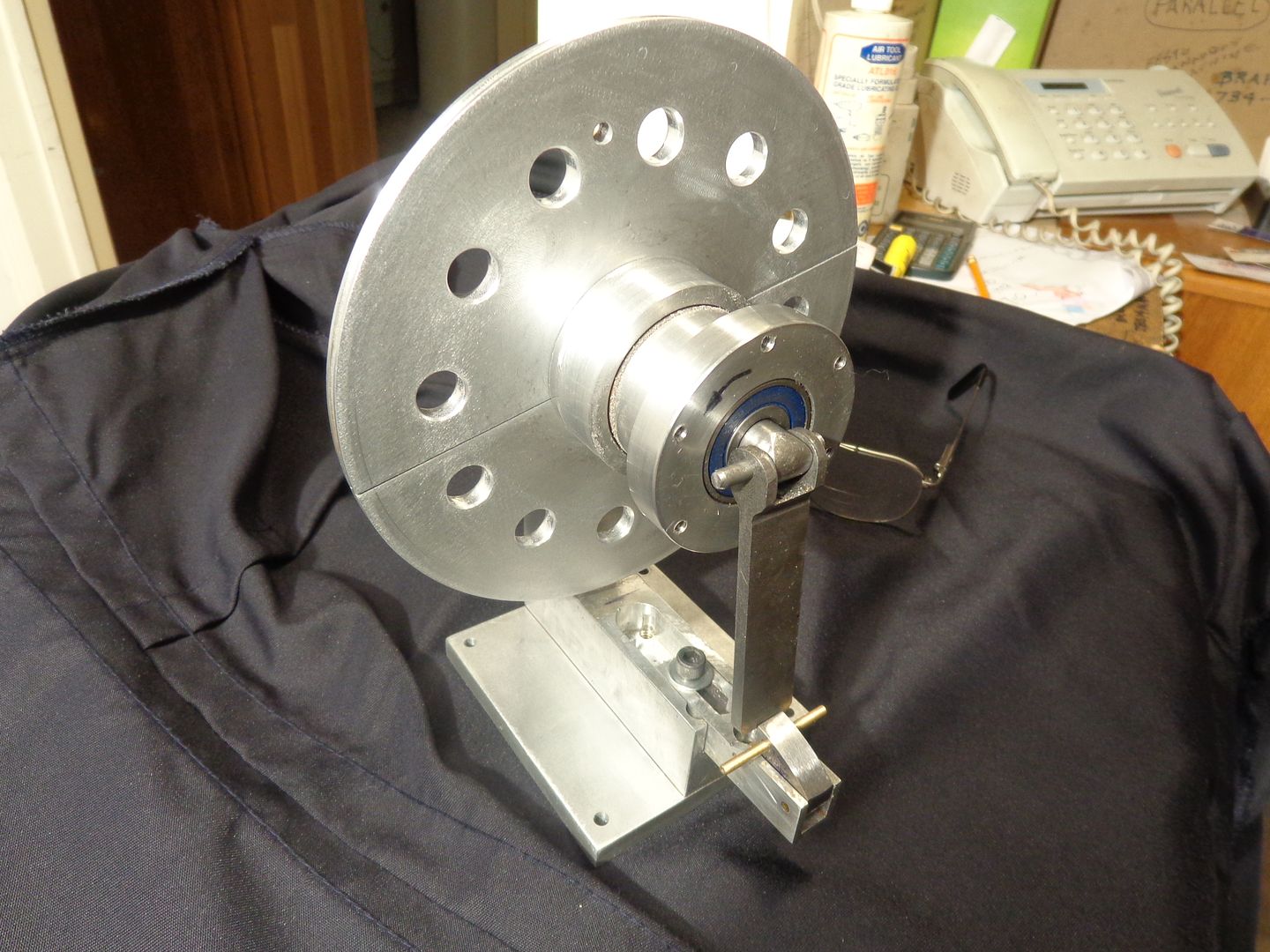

Brian, here is a drawing of a multi-plate type clutch for your application. It's actually a single plate clutch but the rest is based on the multi-plate concept.

If you want more details I'd be happy to supply the models etc. for it.

View attachment Clutch.pdf