Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

Couldn't see a slot for this post really since its not to do with engines, although prompted by my two wobbler's as Christmas presents last year.

I wanted to make something in the workshop that I could give to more members of my 'own' section of the Freeman family. Looking through the Axminster tools website(UK) I came across their gift section and thought I would have a go at making a pen, pen and pencil or fountain pen set. In the end I thought I would try a couple and see if I could do it first.

So I ordered their 2MT pen arbour and a set of bushes for one of their pen types. I must say (and I have nothing to do with the company) that the quality of the pen kits is outstanding. I am pleasantly surprised at the end results. My practice first pen I gave (in its good quality pen box - better than you would get if buying a commercial good quality fountain pen - I know, I have) to the chap I deal with at my local scrap yard and to say he was pleased is an understatement. Worth its wait in gold (well brass really). I don't mean for this to sound a boasting post, only as encouragement if you have ever thought of making a gift. Their (not mine) kit and supporting items are top quality.

To start with I needed to have a tool rest so knocked one up in about an hour. Its main parts are a piece of 3mm angle iron and a suitable strap of steel which I welded together. The inside of the strip has a welded captive nut in the centre so a grub screw connects it to the mounting block. This in turn is screwed onto a plate that is then secured on the top slide of my Myford lathe (refurbishment was covered on this forum - cant seem to get the links button to work. The only adjustment made when tried out was to reduce the height of the block as for my height and comfort I needed to have it a little lower.

A visit to a local tool store saw me come away with the three turning tools recommended on the Axminster site (see their pen turning video) namely a gouge, skew and parting tool. These were not expensive (in case it didn't work) and in use it has gotten me to think that not all wood is 'orible. Indeed I would love to have a go at turning a bowl or something later on and as those who have read some of my posts before know, I HATE wood. Well, until recently that is.

Now armed with all the bits, it was a matter of trial and error. I was expecting to have a few failures at first and that's why Initially only bought two kits. The results I got with the first two however were very good. Surprisingly so! I don't put this down in any way to my skill levels, rather the bits and pieces bought to do the job and their online video, worth a look in anyhow.

My only 'failure' came when I got over confident and it has a top section slightly too long and whilst it works, it needs the clicking part to be depressed a little more than it should do....but I don't care because its in my pocket now....and it mine! One other little nugget is the refills are all the standard and easily available ones.....

So after the first two pens were done I ordered more pens, then ordered a couple of fountain pen kits (they are more expensive but the quality is as good as the others) and now can't stop making the things, its very addictive so beware! I have been asked to make a pen and pencil set and now am worried that this addiction doesn't take over my life. I have had to ration myself now by saying I will only make a pen AFTER I have done my 'other' engineering work, namely the pair of Seals I am building............so beware if your tempted....you could become the new Parker, or ....................

Photos tell the story better..................

The tool rest....

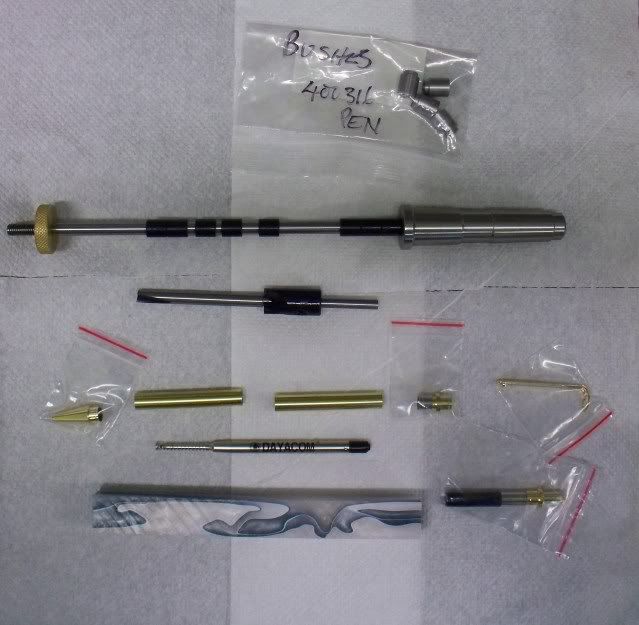

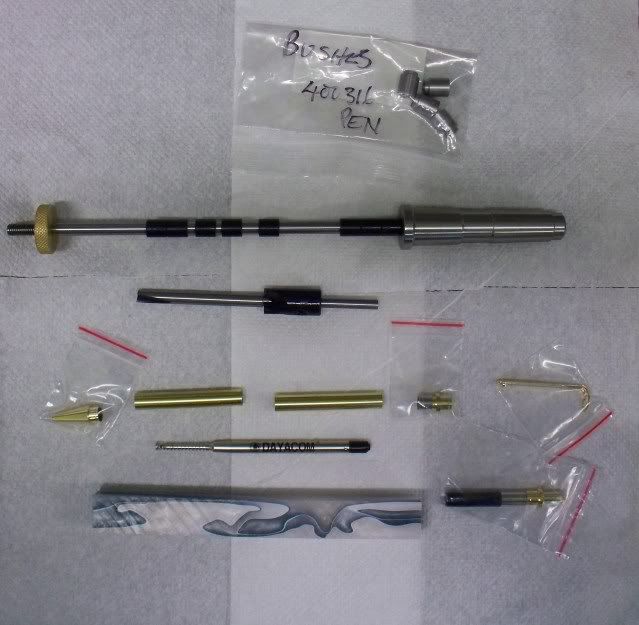

The first order of 'bits'........................

Made a small work bench thingy to keep the bits together..........you can tell I hate normal woodwork.......

The first pen blank on the 'new' rest....................

Getting there..............

The constituent parts....................

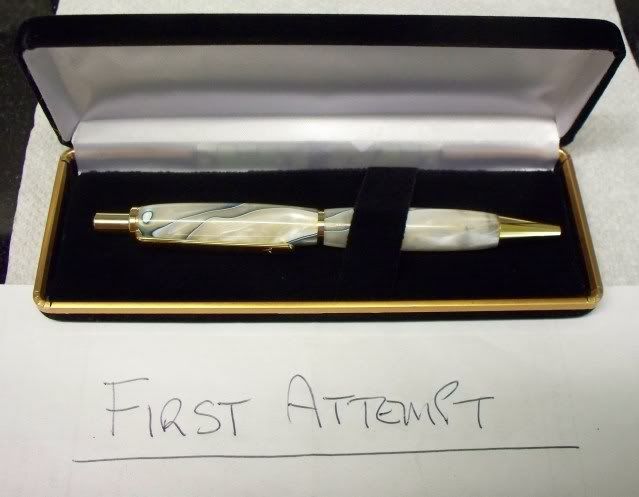

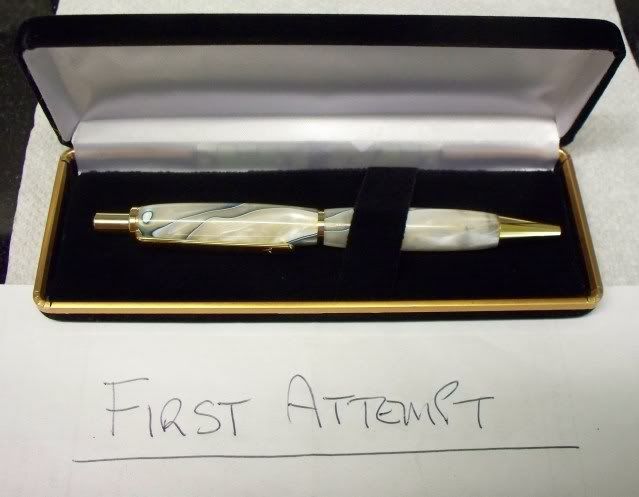

The finished article and the one given to my local scrap yard contact.......................

Finally where I have gotten to so far....................................

I wanted to make something in the workshop that I could give to more members of my 'own' section of the Freeman family. Looking through the Axminster tools website(UK) I came across their gift section and thought I would have a go at making a pen, pen and pencil or fountain pen set. In the end I thought I would try a couple and see if I could do it first.

So I ordered their 2MT pen arbour and a set of bushes for one of their pen types. I must say (and I have nothing to do with the company) that the quality of the pen kits is outstanding. I am pleasantly surprised at the end results. My practice first pen I gave (in its good quality pen box - better than you would get if buying a commercial good quality fountain pen - I know, I have) to the chap I deal with at my local scrap yard and to say he was pleased is an understatement. Worth its wait in gold (well brass really). I don't mean for this to sound a boasting post, only as encouragement if you have ever thought of making a gift. Their (not mine) kit and supporting items are top quality.

To start with I needed to have a tool rest so knocked one up in about an hour. Its main parts are a piece of 3mm angle iron and a suitable strap of steel which I welded together. The inside of the strip has a welded captive nut in the centre so a grub screw connects it to the mounting block. This in turn is screwed onto a plate that is then secured on the top slide of my Myford lathe (refurbishment was covered on this forum - cant seem to get the links button to work. The only adjustment made when tried out was to reduce the height of the block as for my height and comfort I needed to have it a little lower.

A visit to a local tool store saw me come away with the three turning tools recommended on the Axminster site (see their pen turning video) namely a gouge, skew and parting tool. These were not expensive (in case it didn't work) and in use it has gotten me to think that not all wood is 'orible. Indeed I would love to have a go at turning a bowl or something later on and as those who have read some of my posts before know, I HATE wood. Well, until recently that is.

Now armed with all the bits, it was a matter of trial and error. I was expecting to have a few failures at first and that's why Initially only bought two kits. The results I got with the first two however were very good. Surprisingly so! I don't put this down in any way to my skill levels, rather the bits and pieces bought to do the job and their online video, worth a look in anyhow.

My only 'failure' came when I got over confident and it has a top section slightly too long and whilst it works, it needs the clicking part to be depressed a little more than it should do....but I don't care because its in my pocket now....and it mine! One other little nugget is the refills are all the standard and easily available ones.....

So after the first two pens were done I ordered more pens, then ordered a couple of fountain pen kits (they are more expensive but the quality is as good as the others) and now can't stop making the things, its very addictive so beware! I have been asked to make a pen and pencil set and now am worried that this addiction doesn't take over my life. I have had to ration myself now by saying I will only make a pen AFTER I have done my 'other' engineering work, namely the pair of Seals I am building............so beware if your tempted....you could become the new Parker, or ....................

Photos tell the story better..................

The tool rest....

The first order of 'bits'........................

Made a small work bench thingy to keep the bits together..........you can tell I hate normal woodwork.......

The first pen blank on the 'new' rest....................

Getting there..............

The constituent parts....................

The finished article and the one given to my local scrap yard contact.......................

Finally where I have gotten to so far....................................