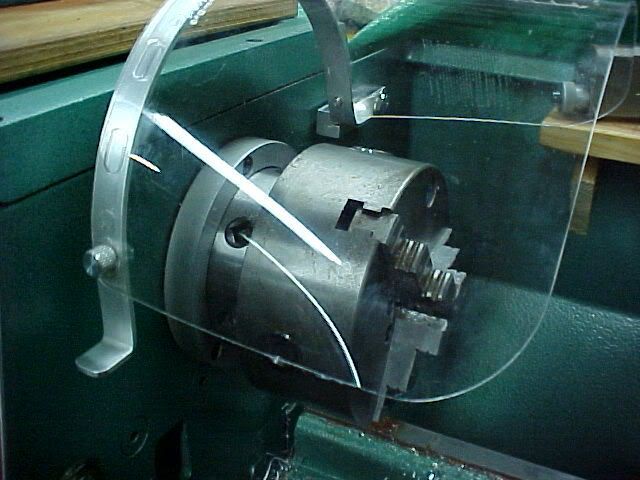

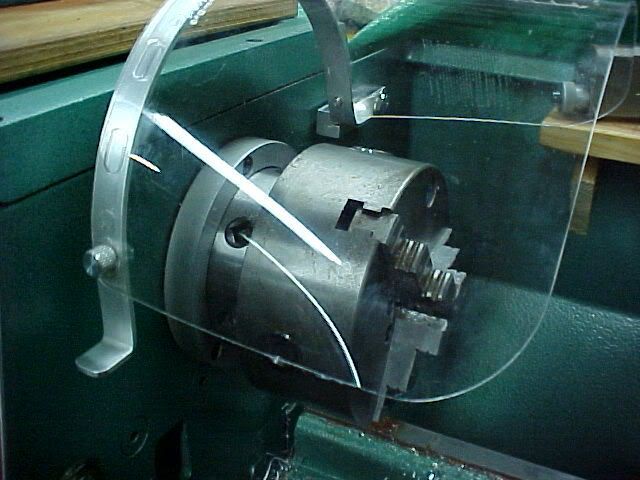

Christmas and Company, had a good day but to much talking, stinking food being cooked, kids , ok, I am done, my wife looked at me and said why don't you go in the shop for a while, thanks for the break out of here, so I wanted to do something quick and easy, so I made bracket that would hold a face shield over the chuck on the 14X40 HF lathe, when I use the cooling fluid it give me a bath when it gets close to the chuck, it hinges on a 1/4 shoulder bolt that is tapped into a 3/4 stock, the grove is 1/4 X 3/8 this lets the shield a place to bottom out, the rear bolt is 1/4" and goes through the chip shield, can angle if it is not the right height, nothing earth shattering but did get my mind off the nut house, glad its only once a year, Lathe Nut