digiex-chris

Well-Known Member

- Joined

- Dec 6, 2010

- Messages

- 263

- Reaction score

- 58

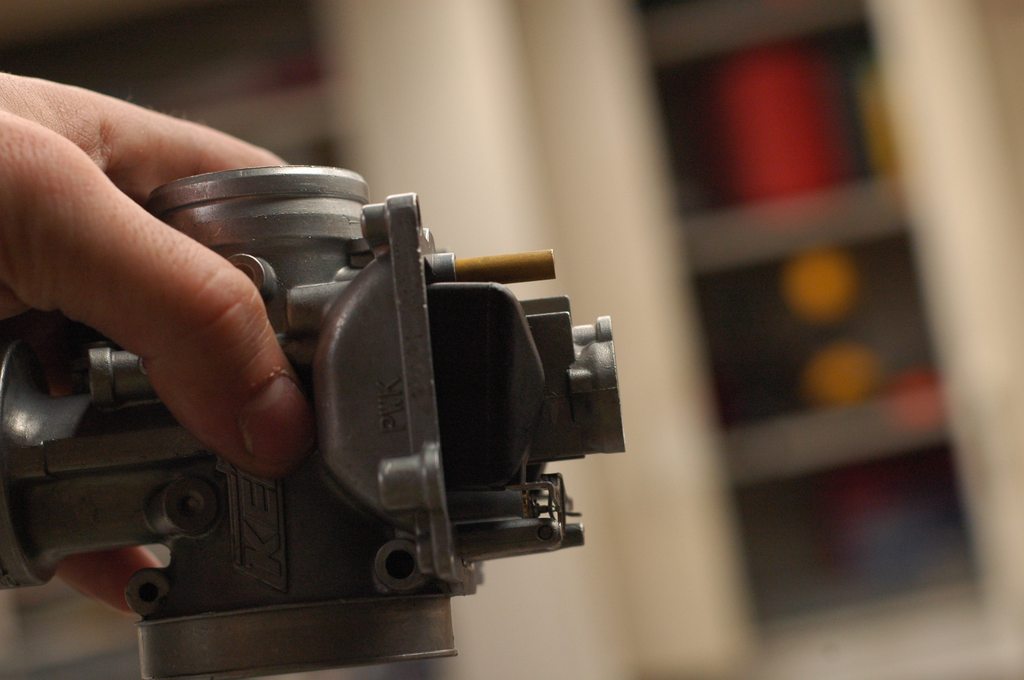

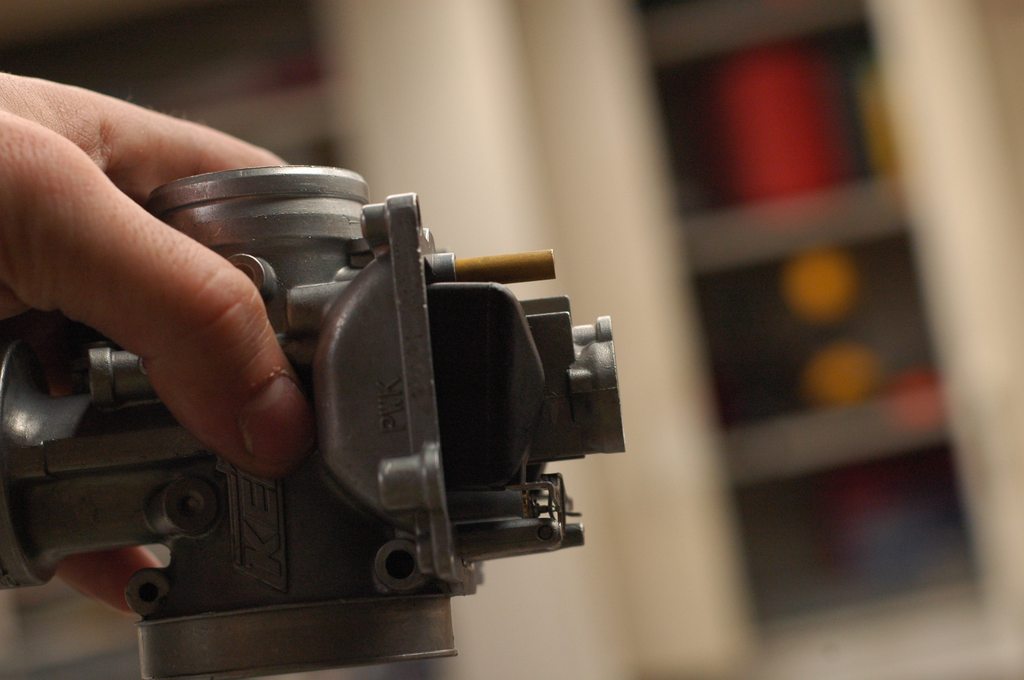

A friend stopped in on Sunday with a dirt bike carb that had a float needle seat in rough shape. Kawasaki says non-replaceable. A lathe says otherwise.

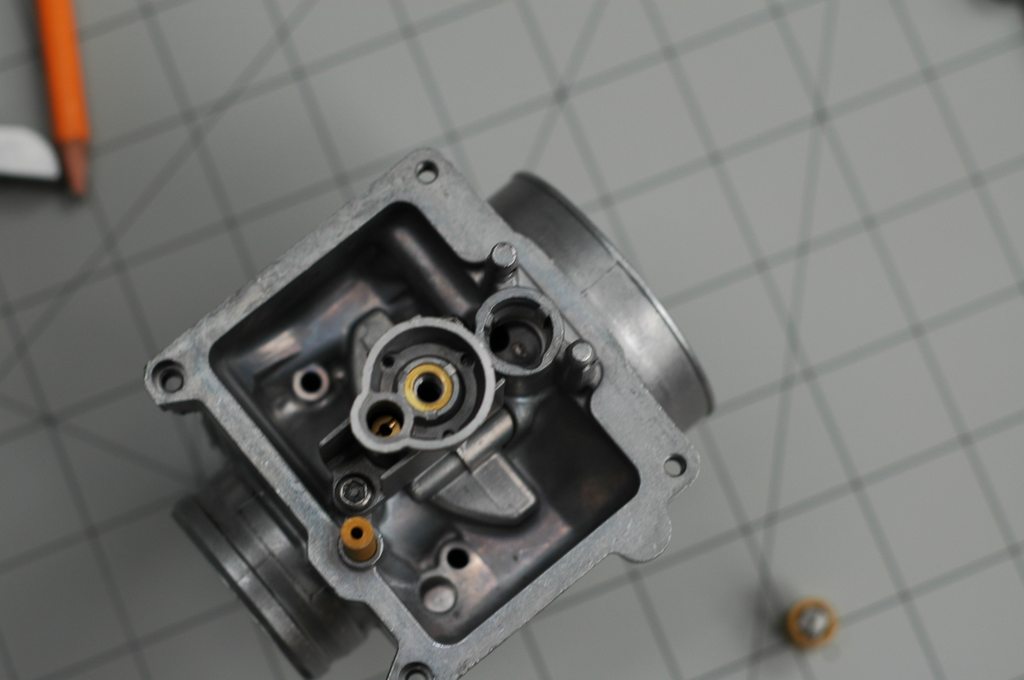

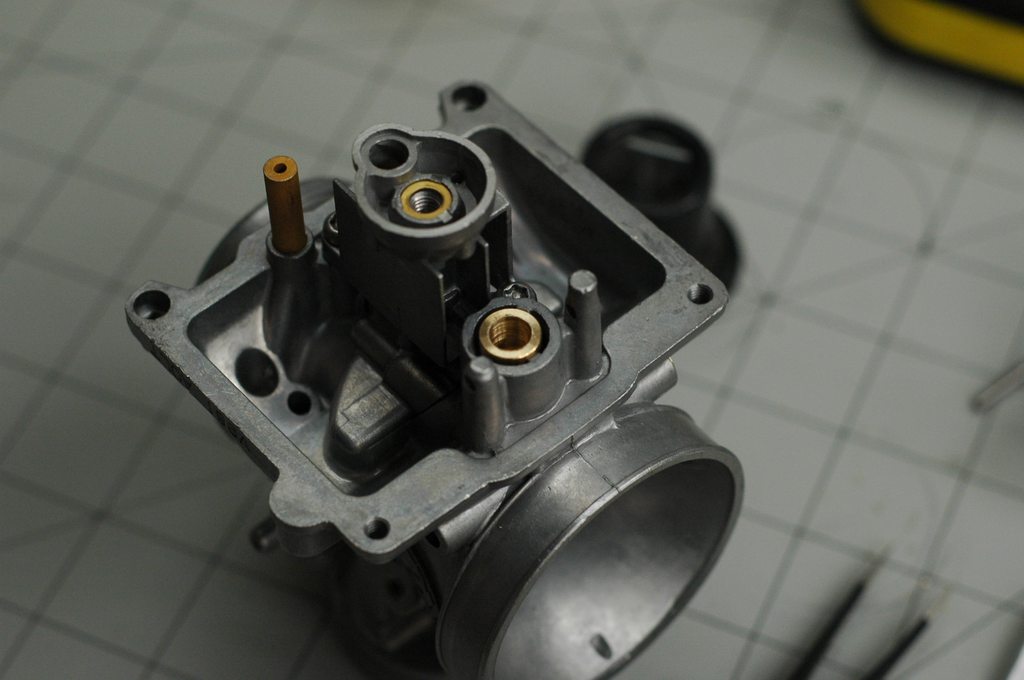

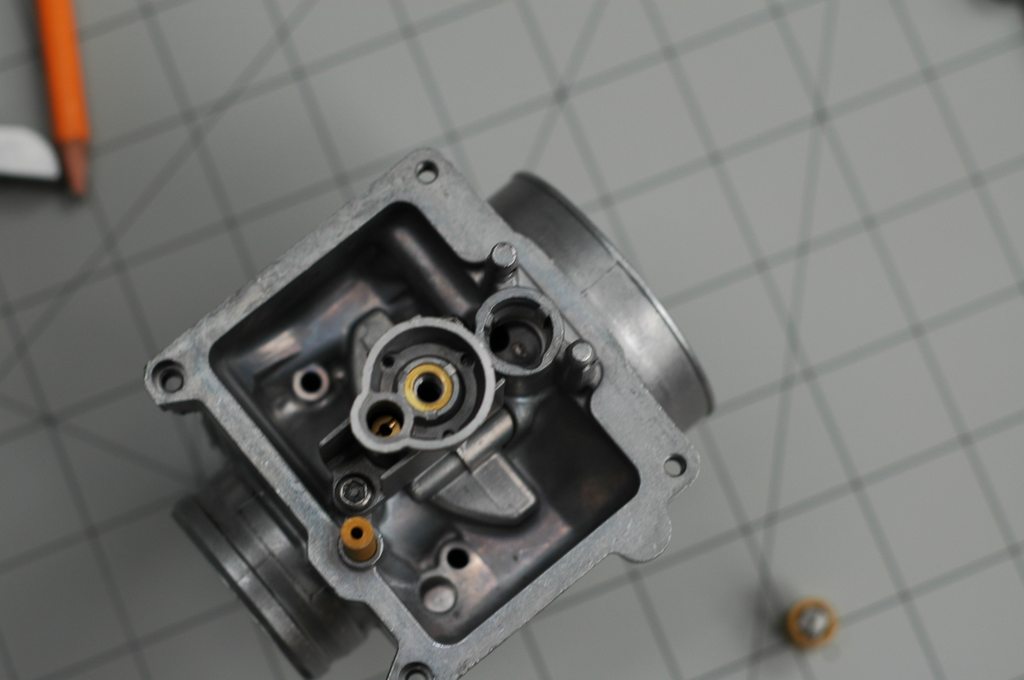

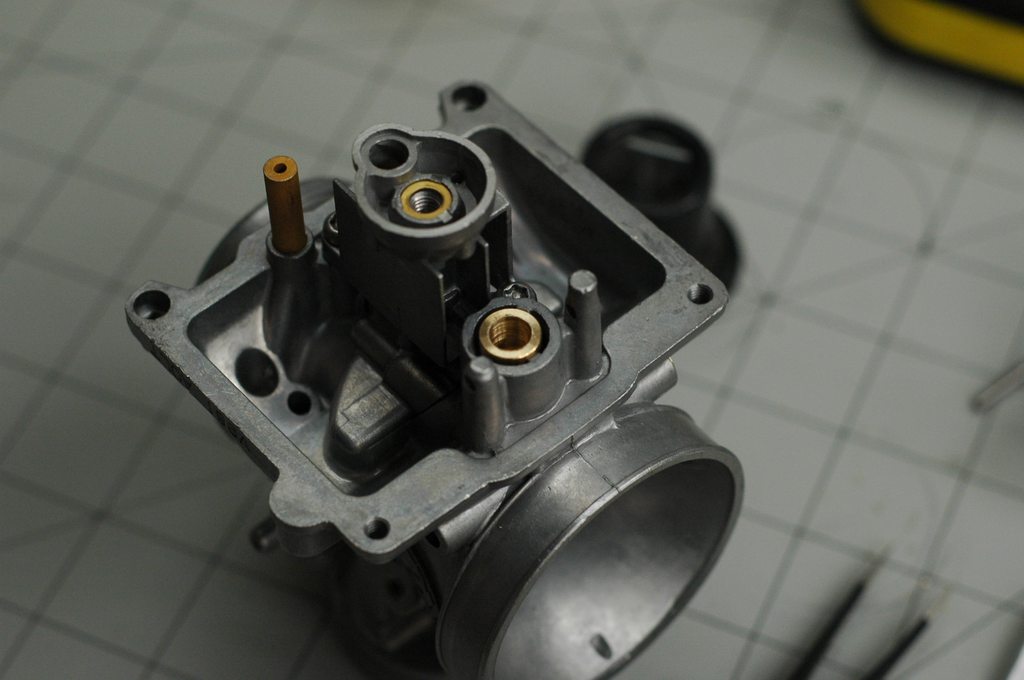

Here's the carb with the seat pulled (using a tap)

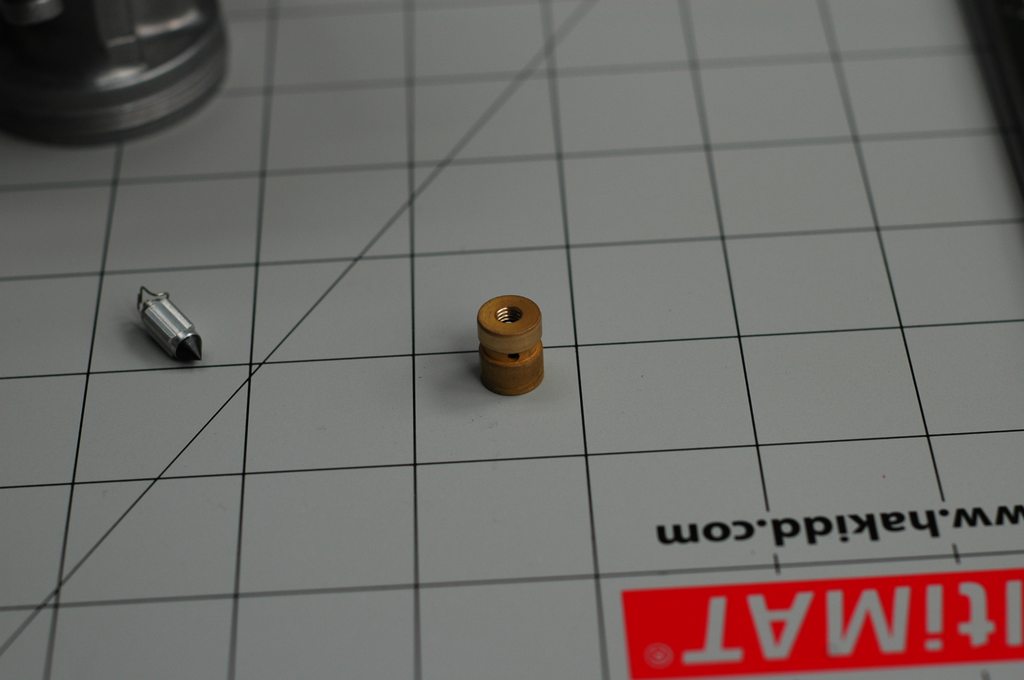

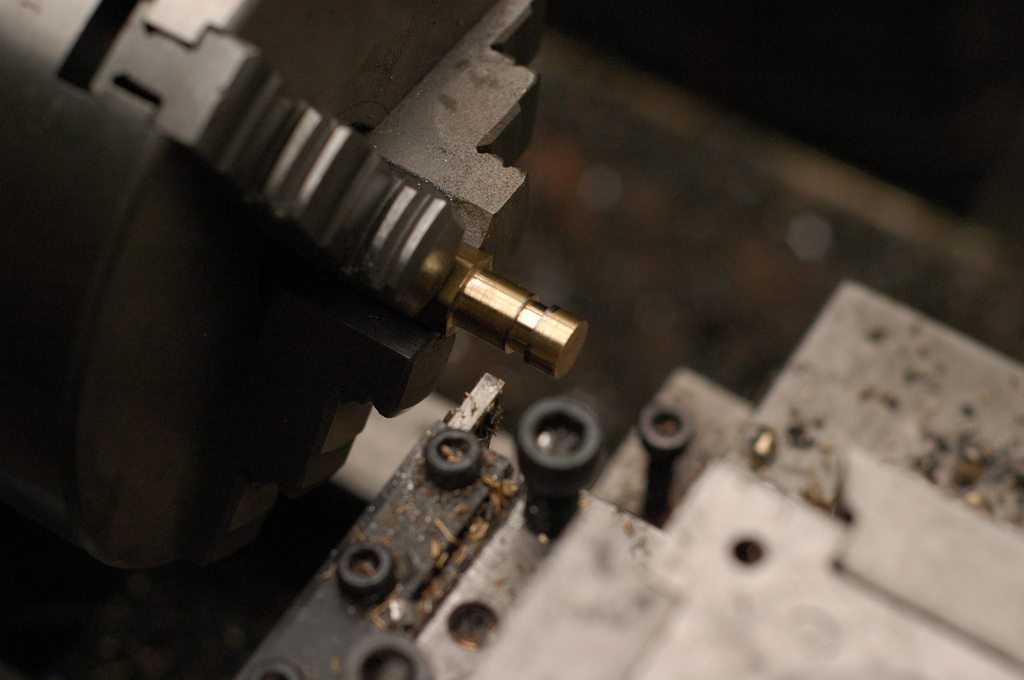

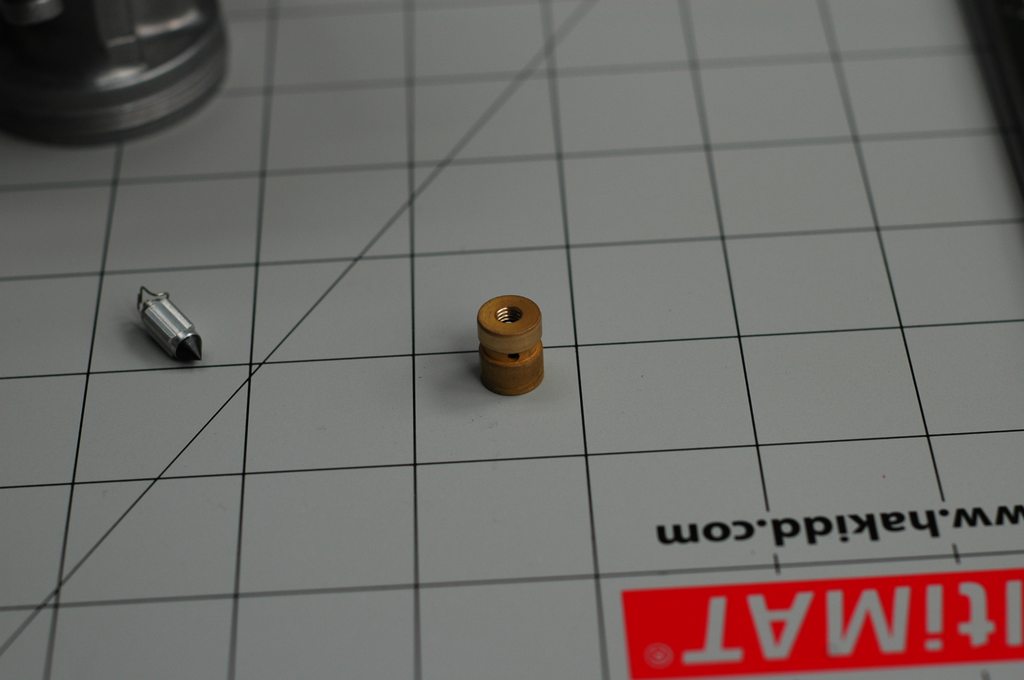

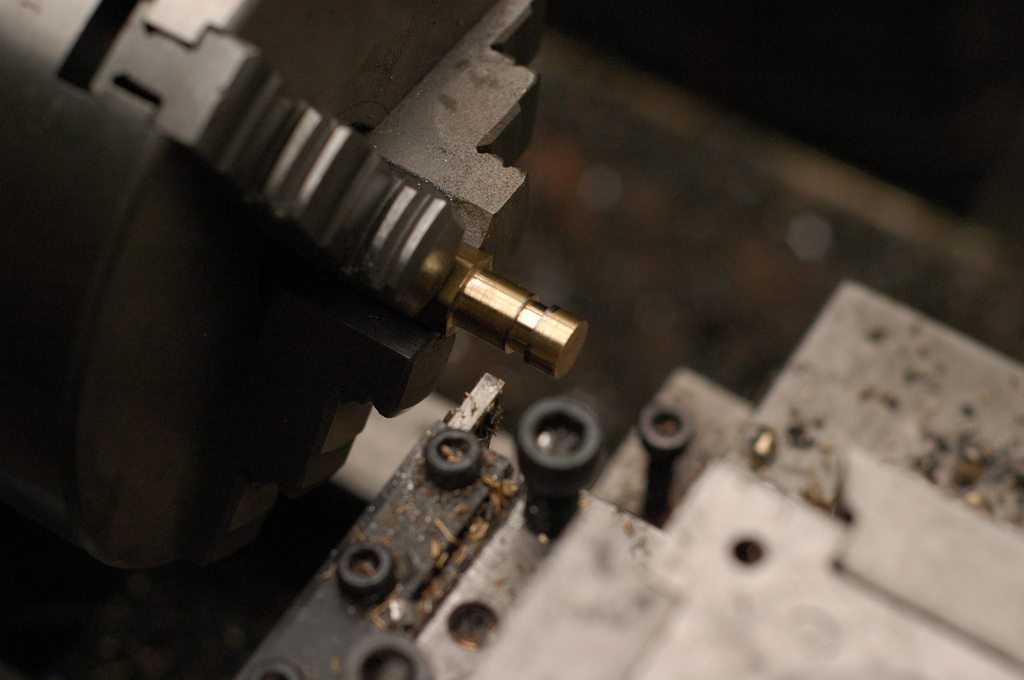

And the seat, with the needle, threads cut by the tap used to pull it

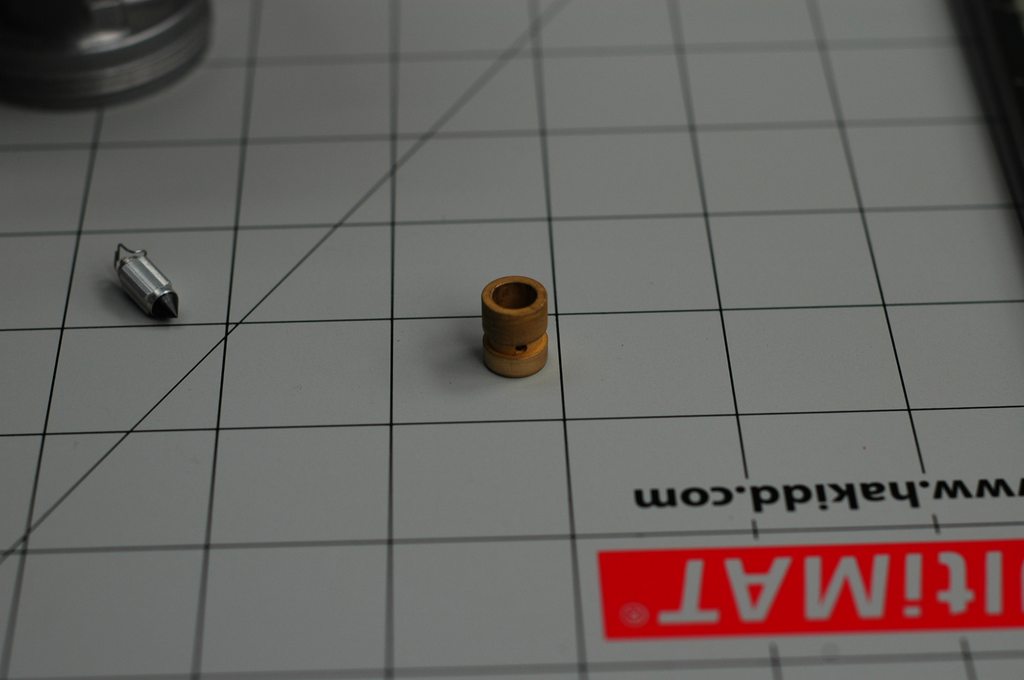

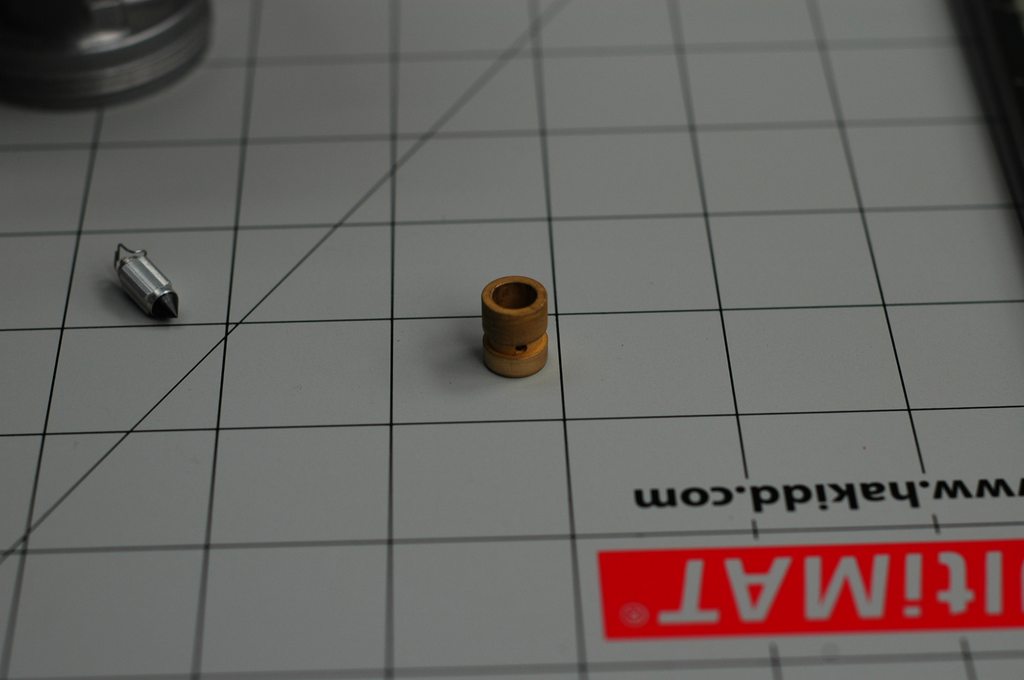

Some nice brass

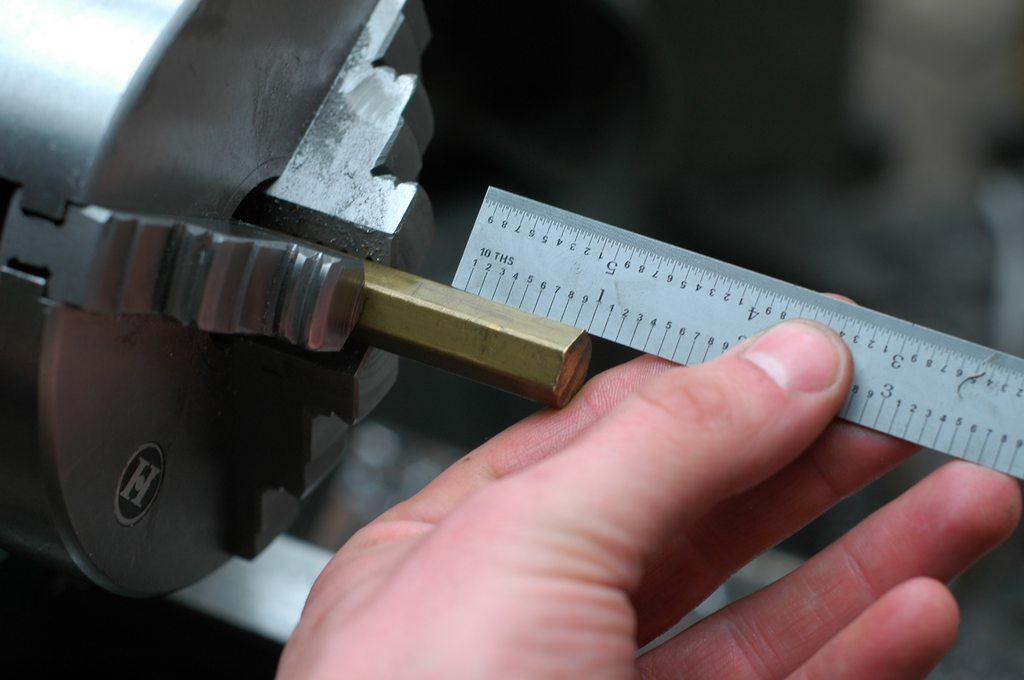

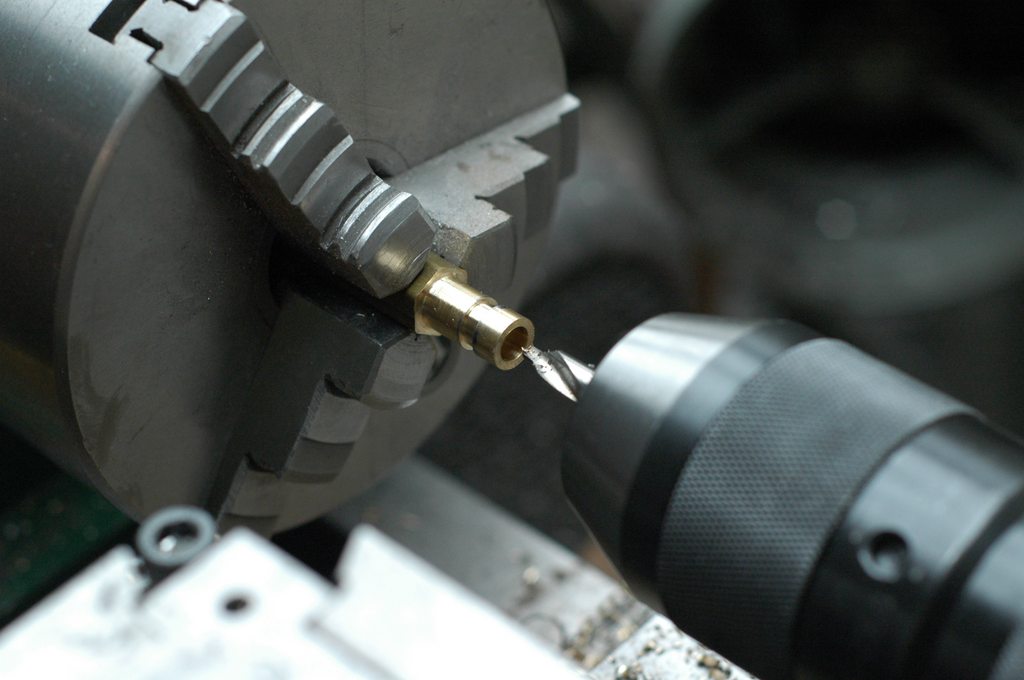

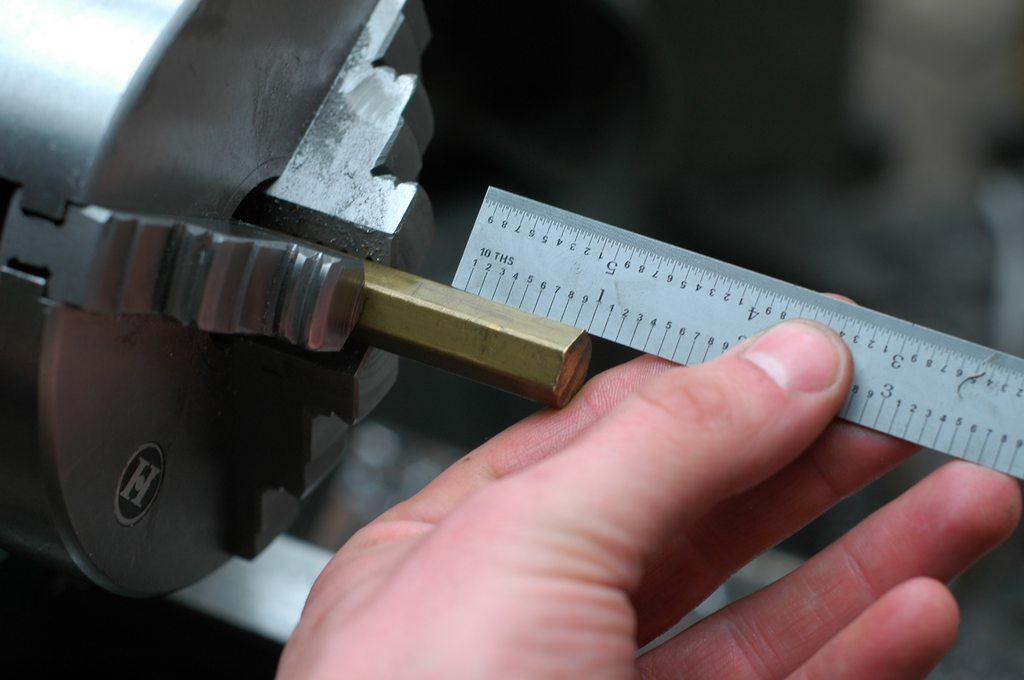

Turned to .3873" (the size of existing one, polished in the last few ten-thousandths). Then I made a D-bit reamer, and smoothed the hole walls and flattened the bottom of the hole. I didn't get pictures of that.

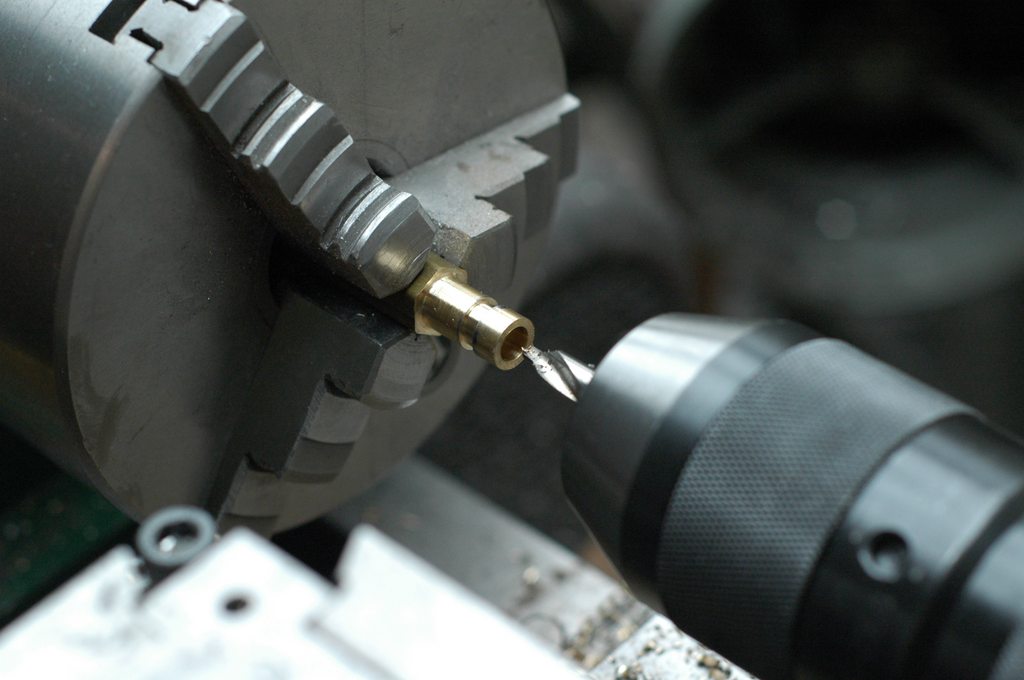

I guessed that since the needle tip was very very close to 60 degrees as measured with the mark 1 eyeball, that it was likely that the seat angle was made by an angle that's extremely common in the machining world, 60 degrees. A lathe center drill was an obvious choice. So I gave it a try.

Parted off, then off to the mill to drill the transfer port holes. Sorry, no pictures of that either. Then I reset the float tang to be horizontal, since I didn't have a good indicator of existing float height before I started due to the seat condition. Then I pressed the new seat in a bit at a time until the float height was to spec.

And using the KLR650 I have to provide about 25 inches of head pressure (way more than a KDX can bring to bear)

No leaks! And for giggles I whipped up a fuel level gauge that screws into where the drain plug goes.

It took me 4 tries to do it. Inopportune entrances into the shop by observers distracted me and I took out the first 2, all with mistakes in polishing in that last ten thousandth to match the press fit as close as I could. The third one I forgot to drill the transfer ports until after I'd pressed it home. The last one I made a 60 degree point on a close fitting aluminum rod to lap the seat angle, but it leaked. I used the center drill, shimmed straight with paper, to touch it up again by hand, and it quit leaking! #4 is the winner.

Just because the manufacturer of something says it's garbage doesn't mean it's not fixable.

Here's the carb with the seat pulled (using a tap)

And the seat, with the needle, threads cut by the tap used to pull it

Some nice brass

Turned to .3873" (the size of existing one, polished in the last few ten-thousandths). Then I made a D-bit reamer, and smoothed the hole walls and flattened the bottom of the hole. I didn't get pictures of that.

I guessed that since the needle tip was very very close to 60 degrees as measured with the mark 1 eyeball, that it was likely that the seat angle was made by an angle that's extremely common in the machining world, 60 degrees. A lathe center drill was an obvious choice. So I gave it a try.

Parted off, then off to the mill to drill the transfer port holes. Sorry, no pictures of that either. Then I reset the float tang to be horizontal, since I didn't have a good indicator of existing float height before I started due to the seat condition. Then I pressed the new seat in a bit at a time until the float height was to spec.

And using the KLR650 I have to provide about 25 inches of head pressure (way more than a KDX can bring to bear)

No leaks! And for giggles I whipped up a fuel level gauge that screws into where the drain plug goes.

It took me 4 tries to do it. Inopportune entrances into the shop by observers distracted me and I took out the first 2, all with mistakes in polishing in that last ten thousandth to match the press fit as close as I could. The third one I forgot to drill the transfer ports until after I'd pressed it home. The last one I made a 60 degree point on a close fitting aluminum rod to lap the seat angle, but it leaked. I used the center drill, shimmed straight with paper, to touch it up again by hand, and it quit leaking! #4 is the winner.

Just because the manufacturer of something says it's garbage doesn't mean it's not fixable.

Last edited: