You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building Rudy's Steam Tractor

- Thread starter 4156df

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Feb 25, 2008

- Messages

- 464

- Reaction score

- 5

Jeff, Jack & Arnold...Thank you.

I'm with you. It's a shame to have those levers there not doing anything.

Post #47

Throttle Linkage

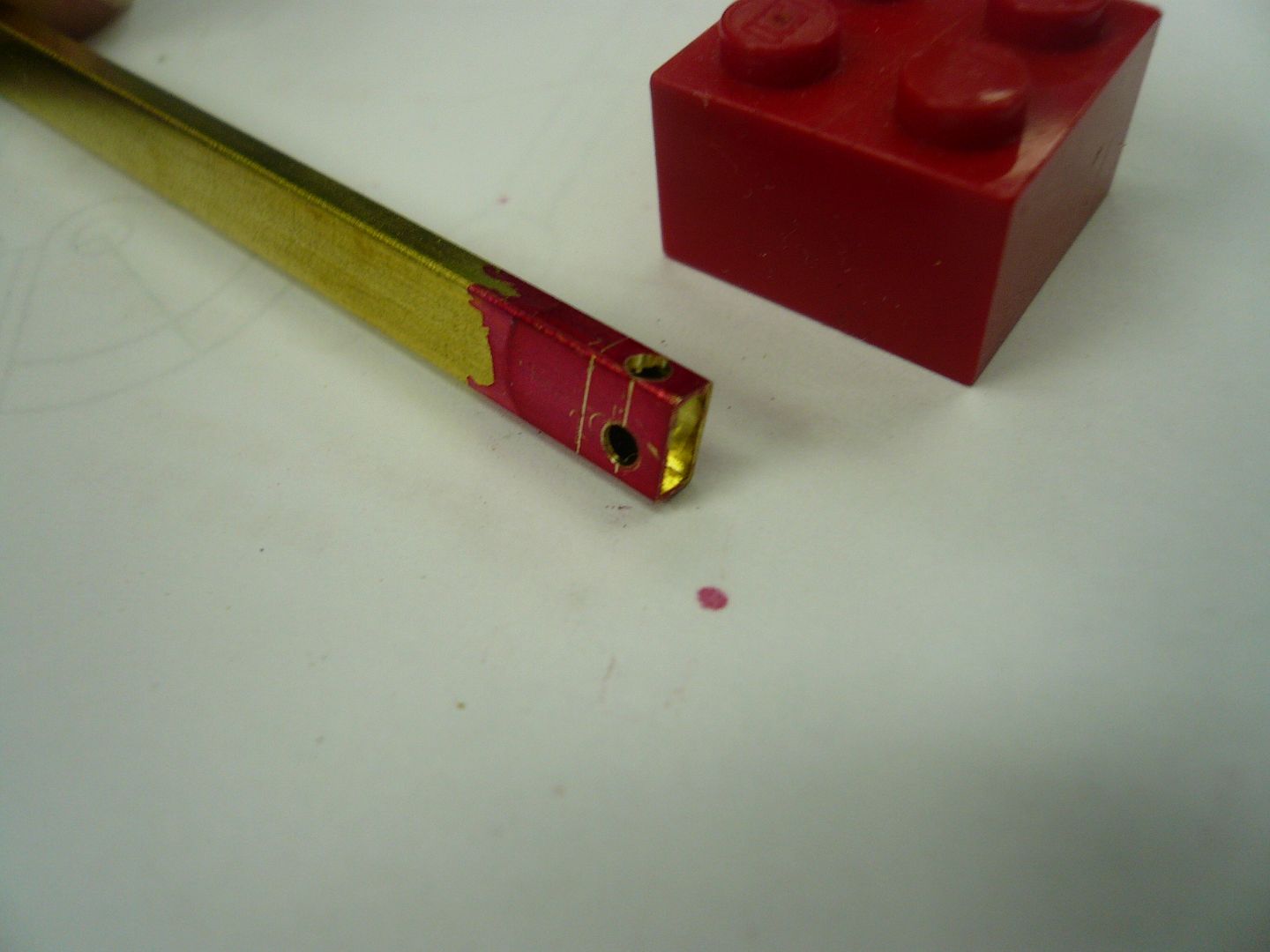

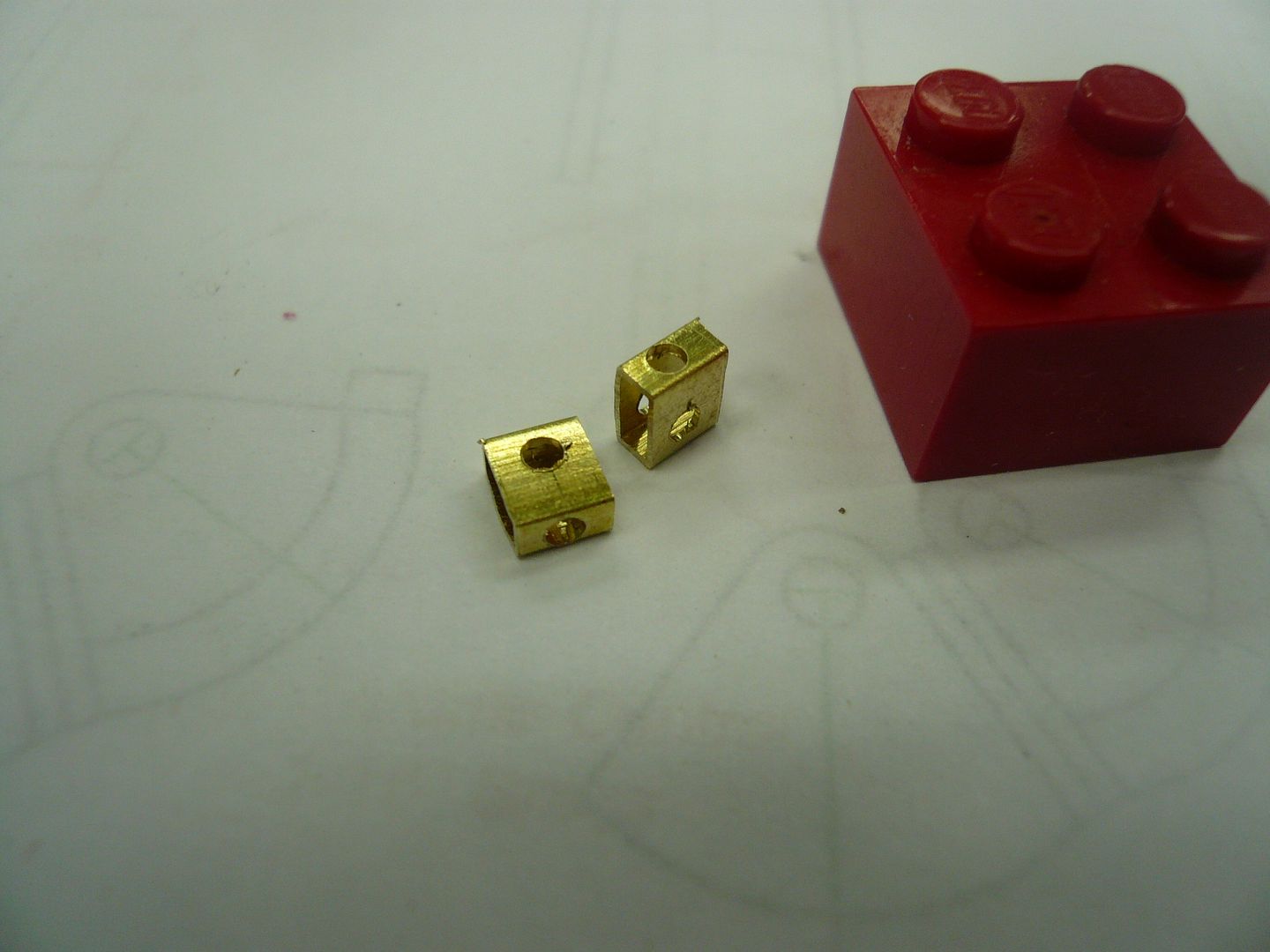

The throttle lever and throttle are connected by a 1/16 rod. The plans are silent about how the ends are attached, but from the photos it looks like Rudy used L bends on his. Im going to use a light clevis on each end.

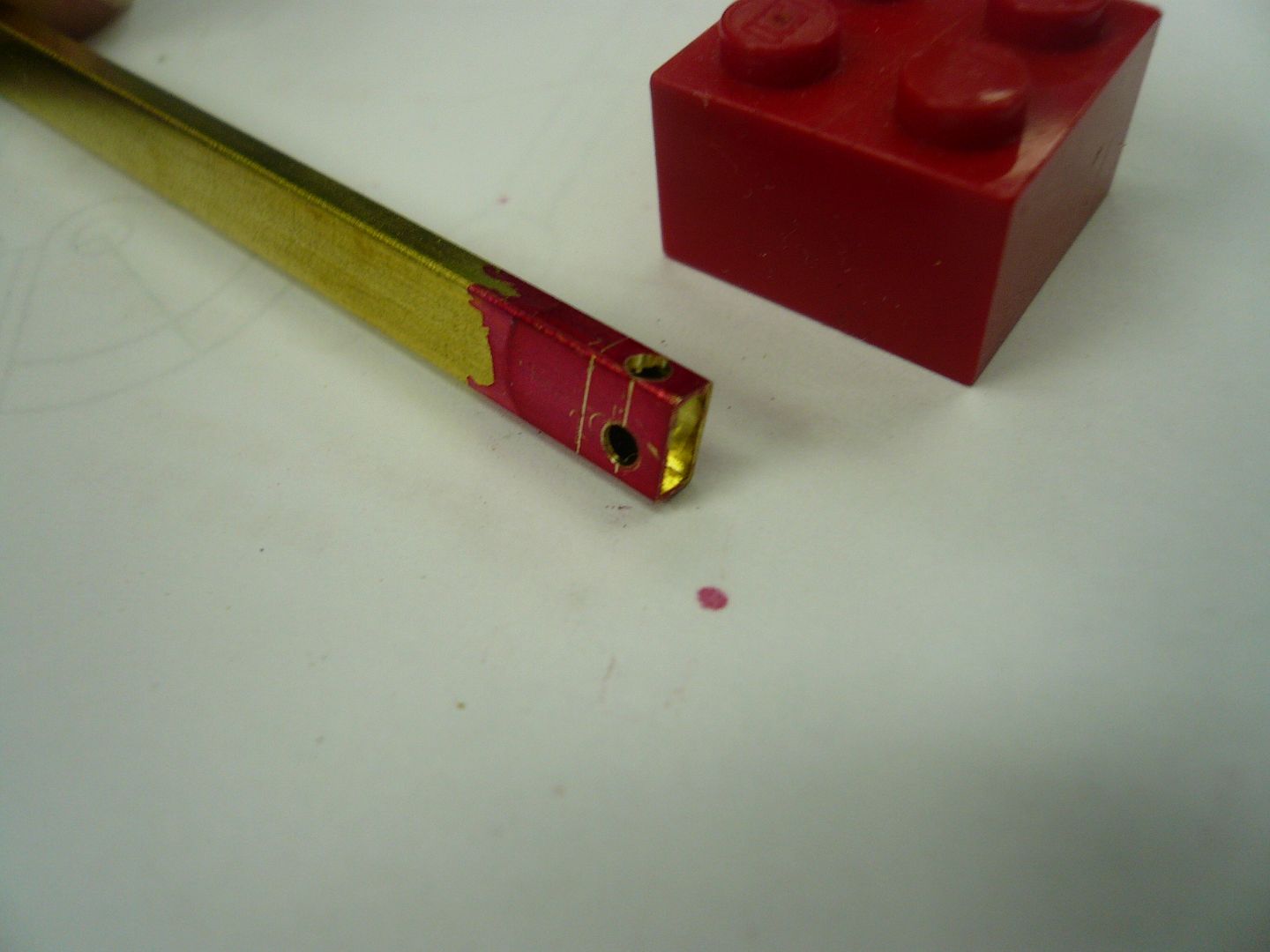

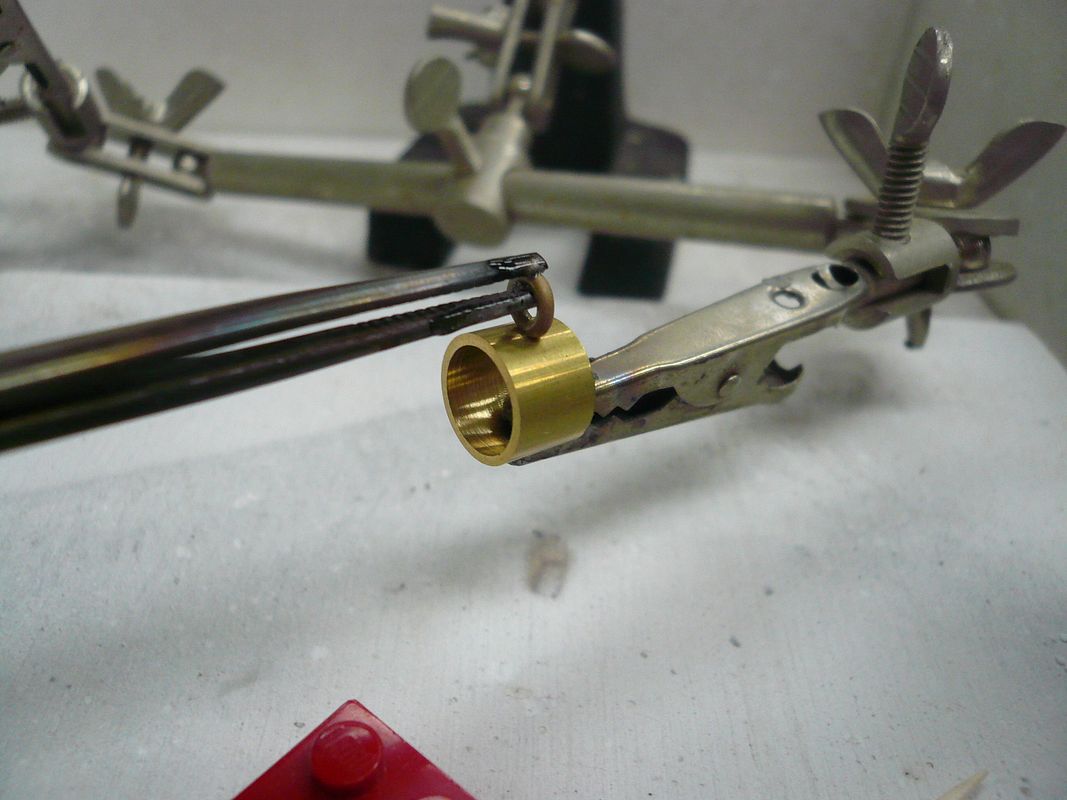

I made the clevises by starting with a piece of 1/8 x 3/16 0.014 wall tubing and then drilling 1/16 holes for a clevis pin and the throttle rod.

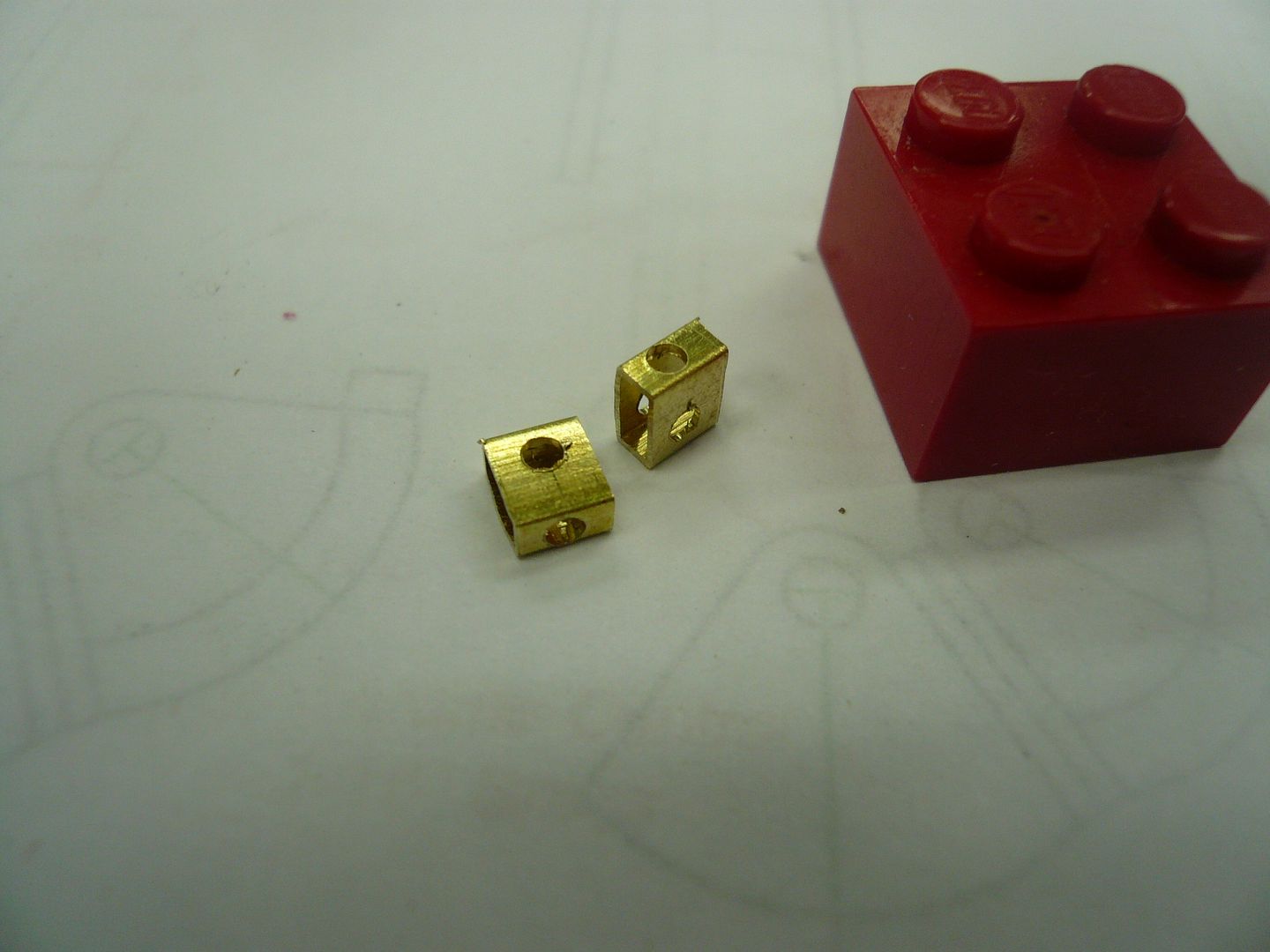

After drilling the pieces are cut off 3/16 long.

The hole for the throttle rod wasnt actually necessary, but it helped locate the piece for soldering.

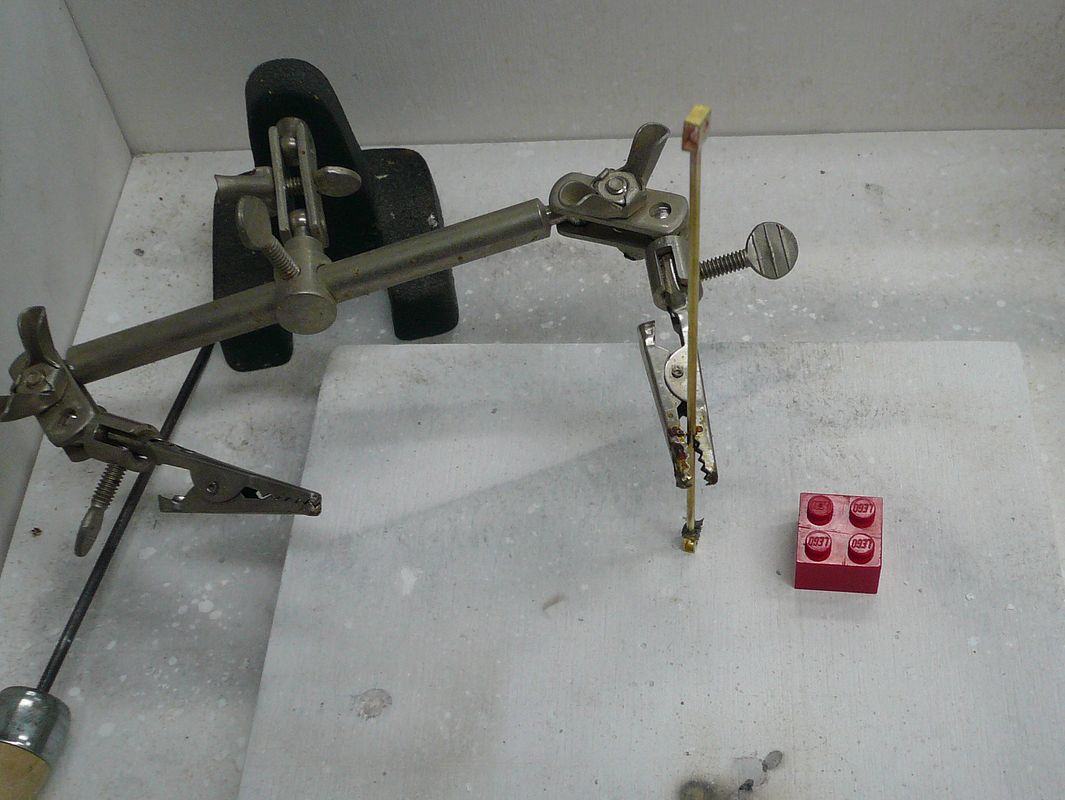

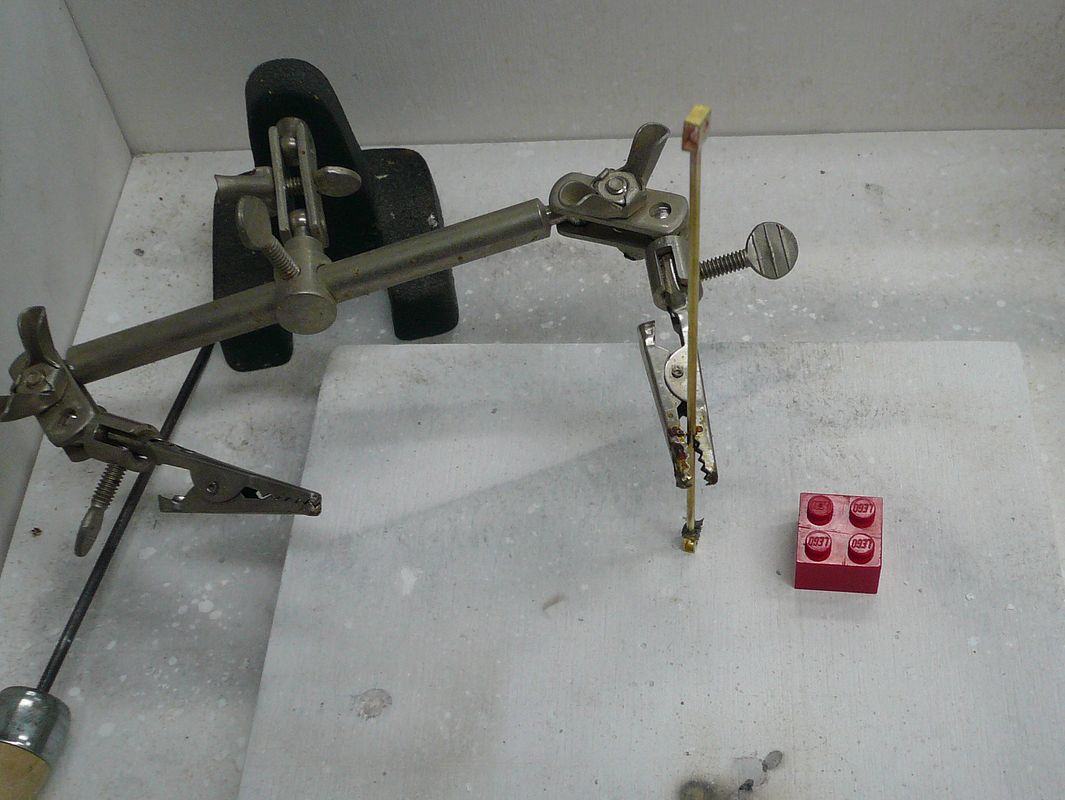

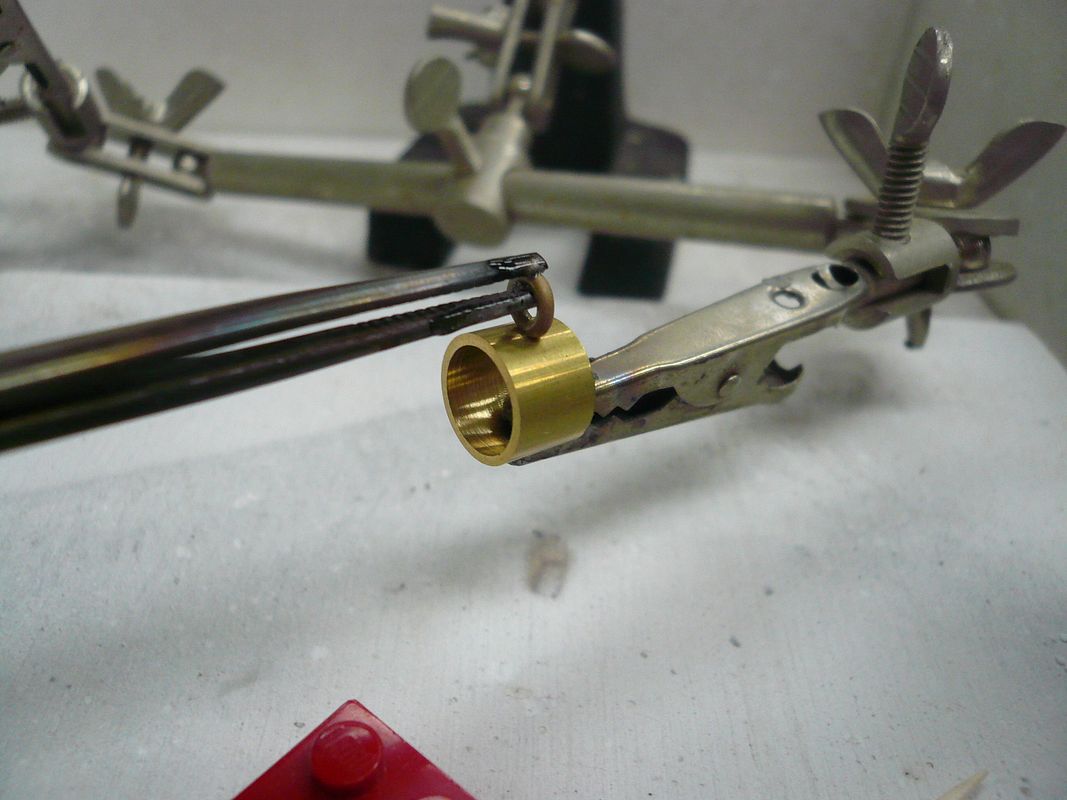

I used silver solder paste and a third hand for holding. Note the top end is already soldered on.

After soldering, the end of the rectangular tube was ground off and rounded to form the clevis.

The clevis pins are made from 1/16 rivets drilled #60 (0.040) for a cotter pin.

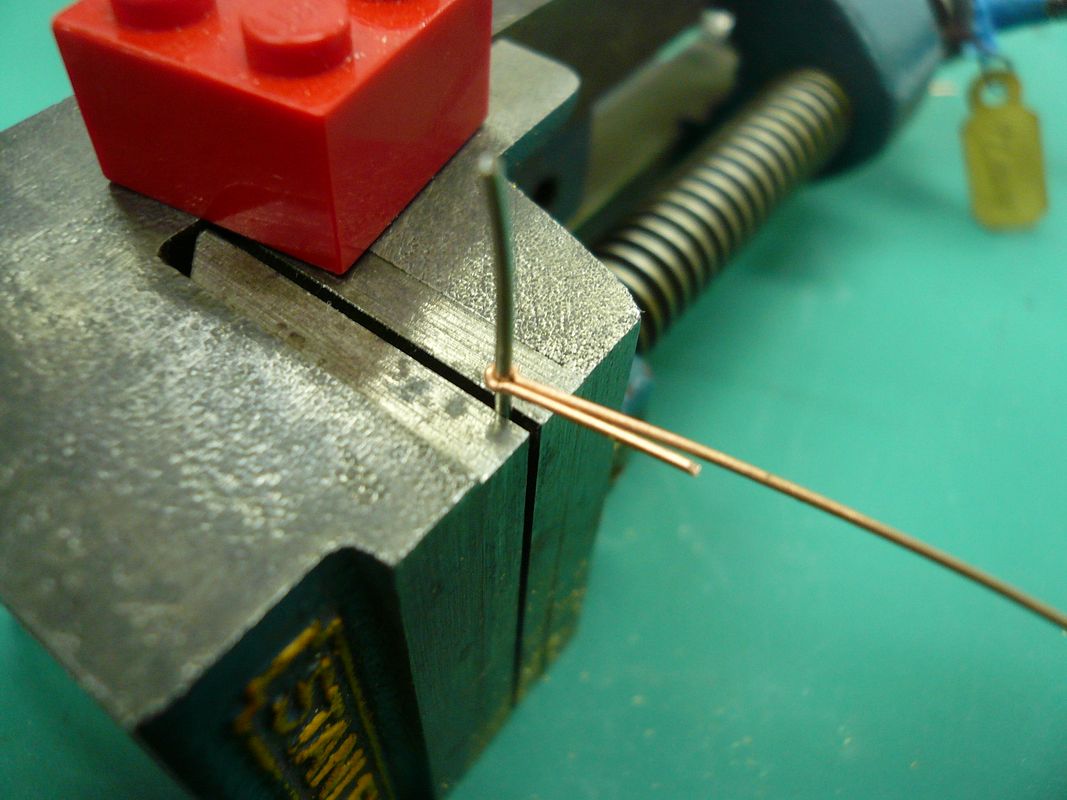

The cotter pins are made using 0.020 copper wire formed around a piece of 0.041 wire.

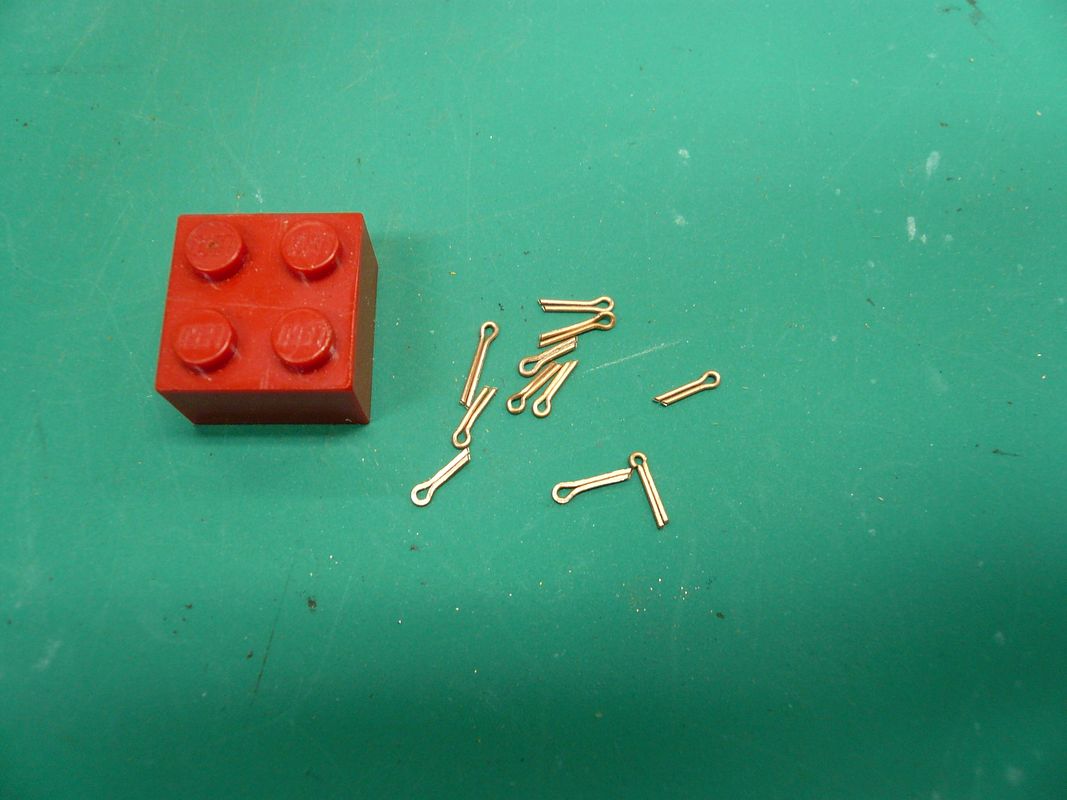

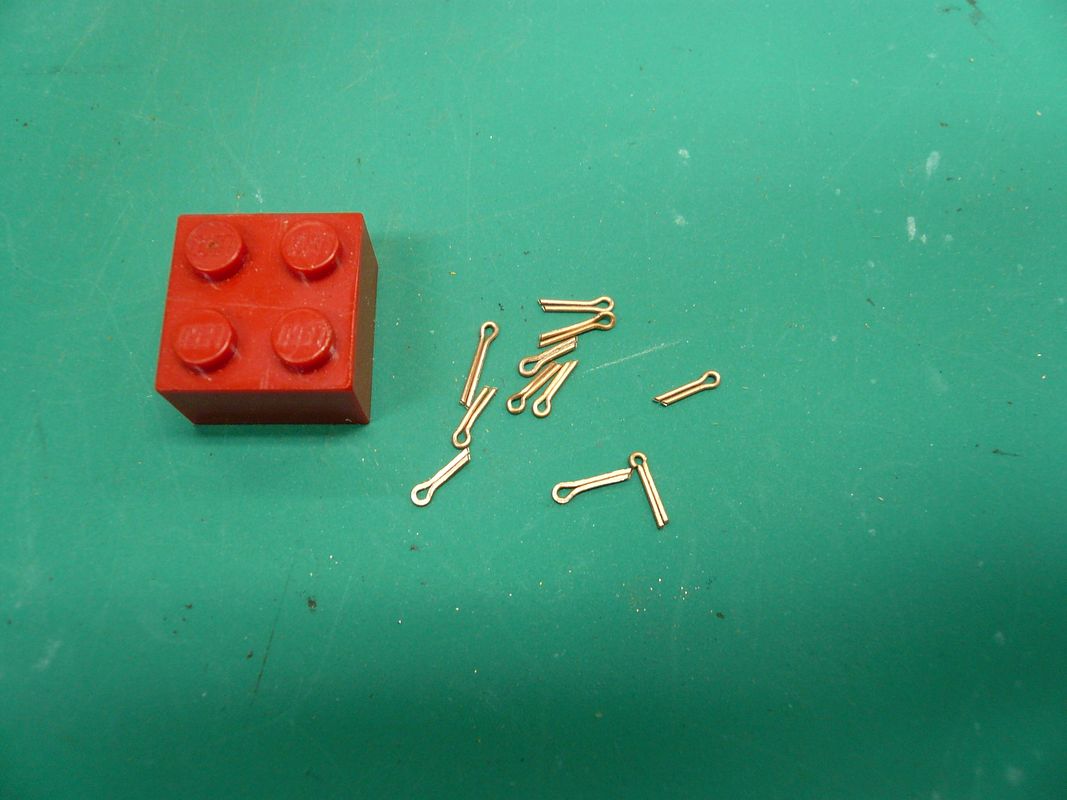

They didnt all turn out. Heres a shot of some good, bad, and ugly ones.

I also discovered that its tough to get two 0.020 wires through a 0.040 hole, so I ended up flattening one side of the wire by drawing it under a file held on a hardened steel plate and then forming the pin. Same as real cotter pins.

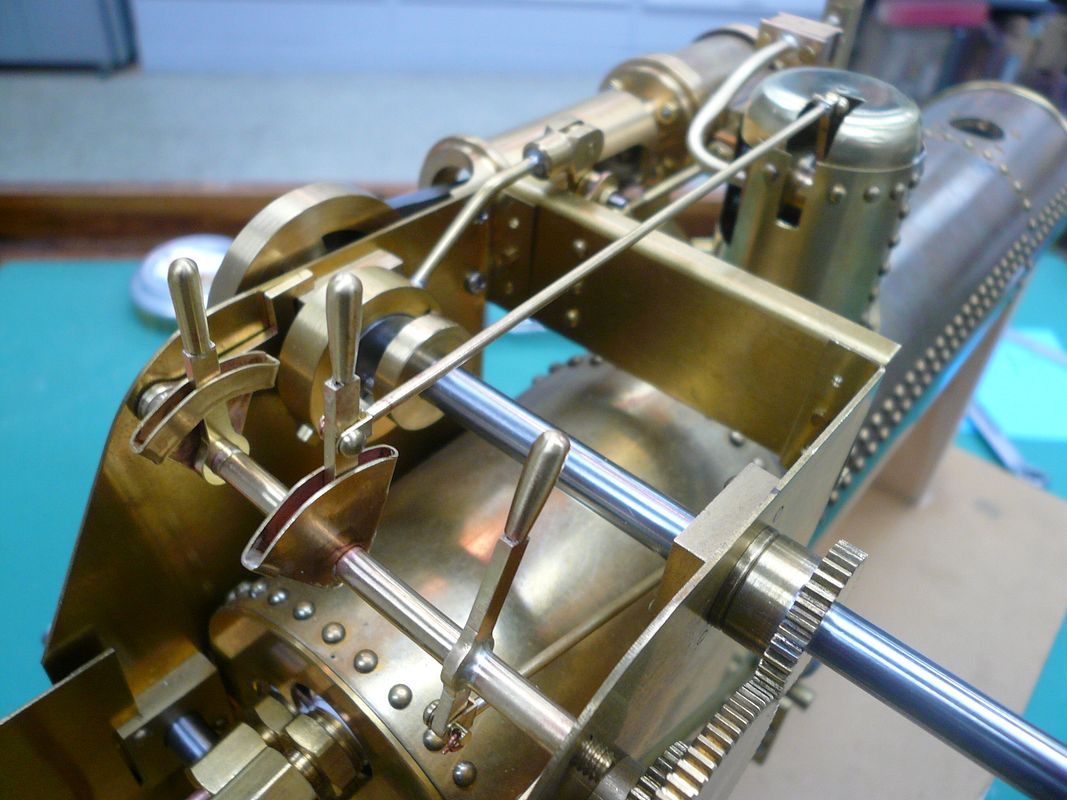

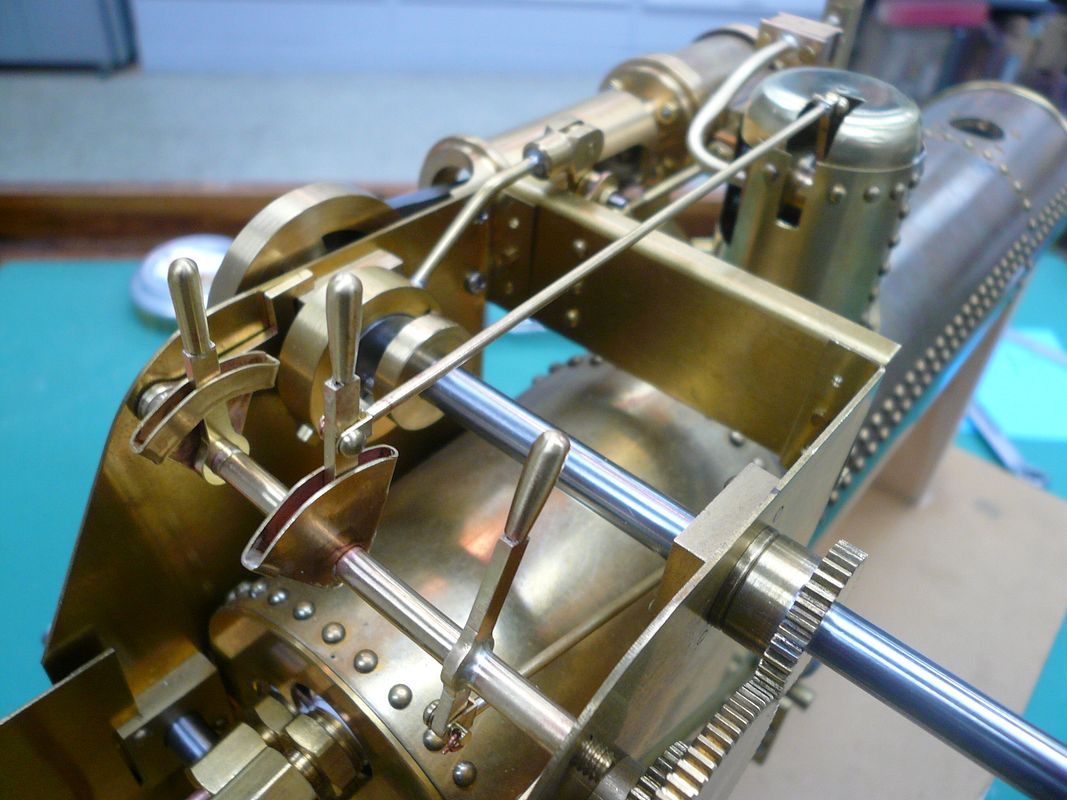

Anyway, heres the rod in place.

For now, the pins are just held with a piece of wire. Now that I look at this picture, I can see that the heads of the pins are way out of scale. Ill have to grind them smaller. Thats one Ill add to the list of things to do later while Im waiting for the paint to dry.

Thats it for today. Sorry about the short post, but not much shop time this week.

Dennis

Jim,there HAS to be a way to incorporate engine reversing and a clutch mechanism to those dummy levers

I'm with you. It's a shame to have those levers there not doing anything.

Post #47

Throttle Linkage

The throttle lever and throttle are connected by a 1/16 rod. The plans are silent about how the ends are attached, but from the photos it looks like Rudy used L bends on his. Im going to use a light clevis on each end.

I made the clevises by starting with a piece of 1/8 x 3/16 0.014 wall tubing and then drilling 1/16 holes for a clevis pin and the throttle rod.

After drilling the pieces are cut off 3/16 long.

The hole for the throttle rod wasnt actually necessary, but it helped locate the piece for soldering.

I used silver solder paste and a third hand for holding. Note the top end is already soldered on.

After soldering, the end of the rectangular tube was ground off and rounded to form the clevis.

The clevis pins are made from 1/16 rivets drilled #60 (0.040) for a cotter pin.

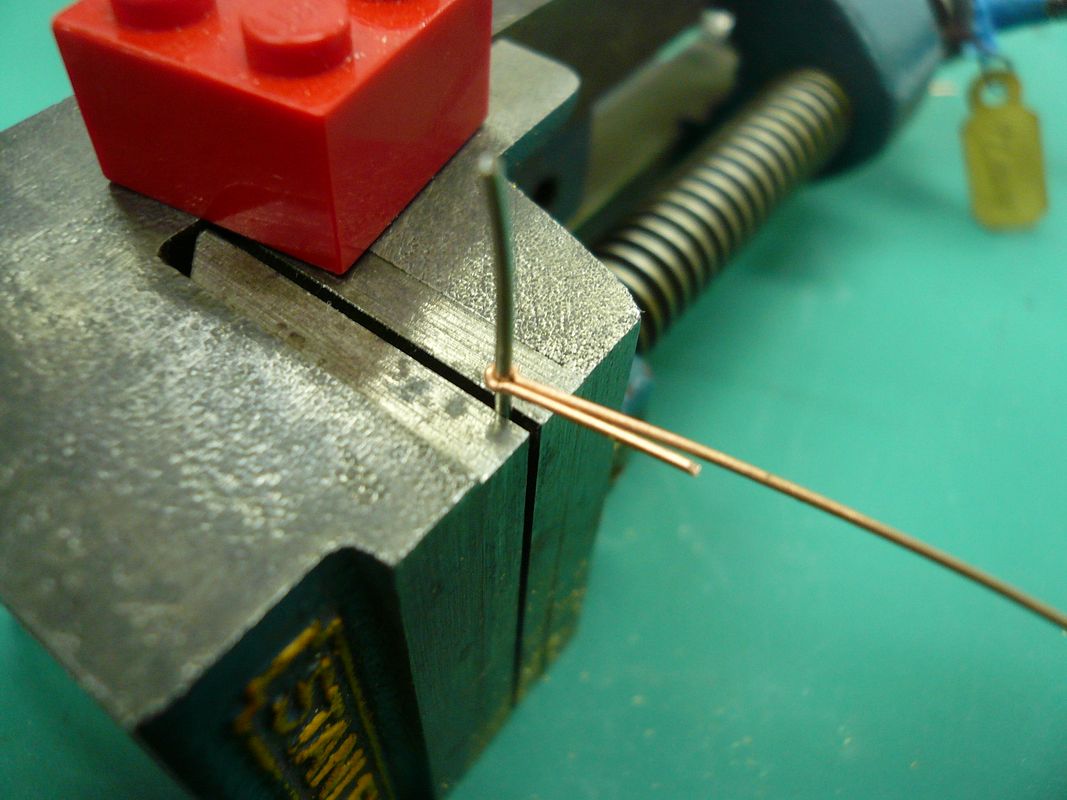

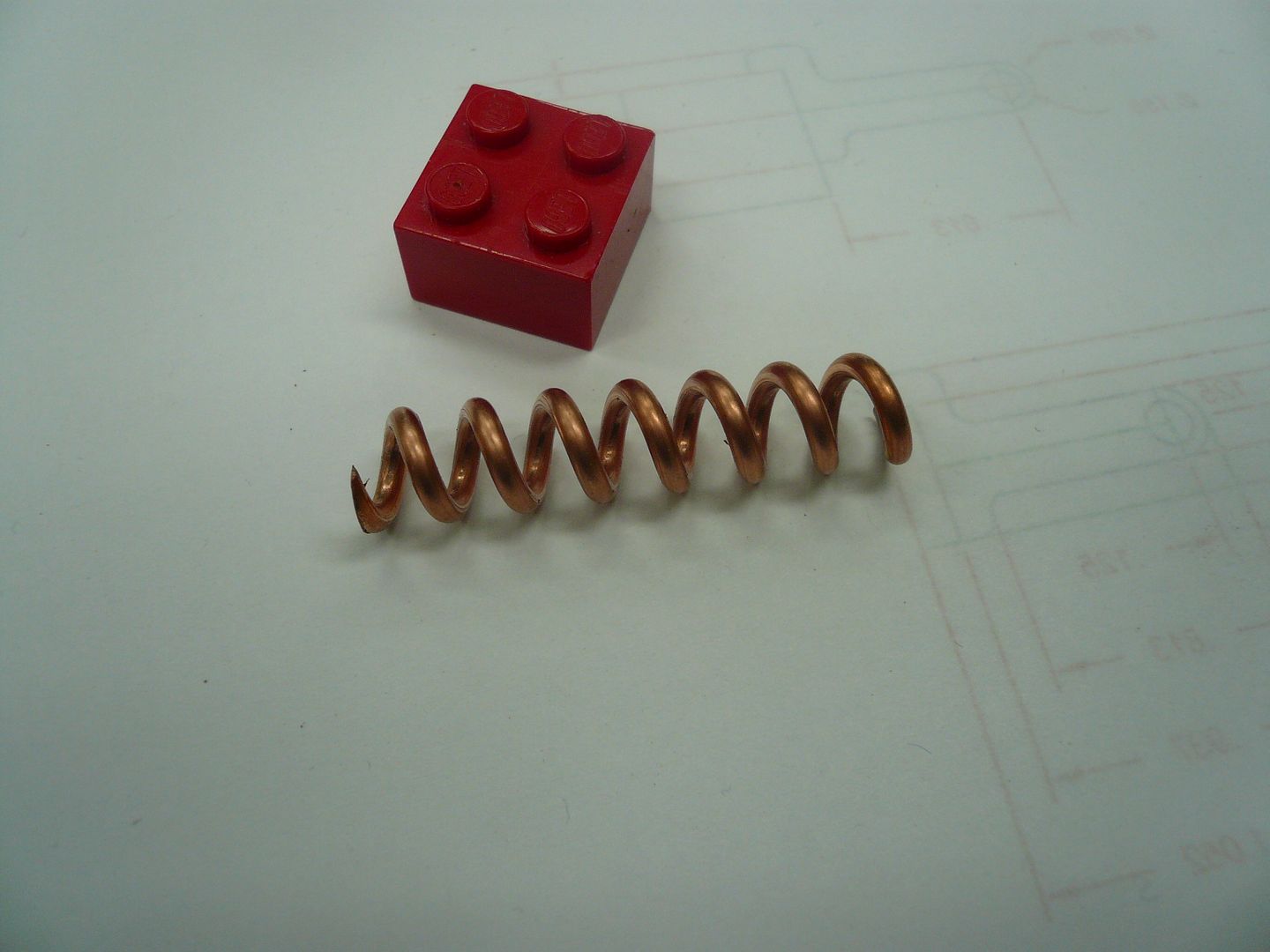

The cotter pins are made using 0.020 copper wire formed around a piece of 0.041 wire.

They didnt all turn out. Heres a shot of some good, bad, and ugly ones.

I also discovered that its tough to get two 0.020 wires through a 0.040 hole, so I ended up flattening one side of the wire by drawing it under a file held on a hardened steel plate and then forming the pin. Same as real cotter pins.

Anyway, heres the rod in place.

For now, the pins are just held with a piece of wire. Now that I look at this picture, I can see that the heads of the pins are way out of scale. Ill have to grind them smaller. Thats one Ill add to the list of things to do later while Im waiting for the paint to dry.

Thats it for today. Sorry about the short post, but not much shop time this week.

Dennis

- Joined

- Feb 25, 2008

- Messages

- 464

- Reaction score

- 5

Dean, Jim, Speedy...Thanks for watching.

Post #48

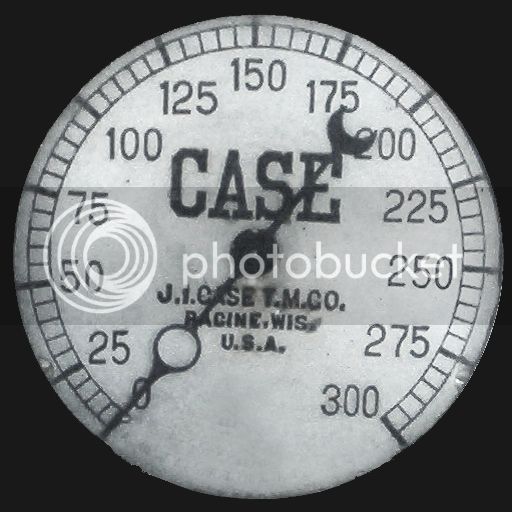

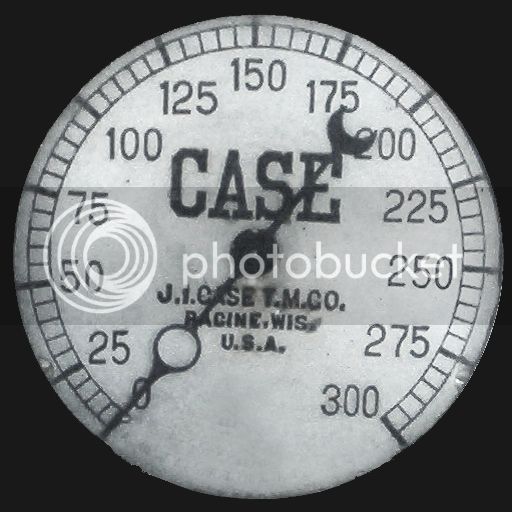

Dummy Pressure Gauge

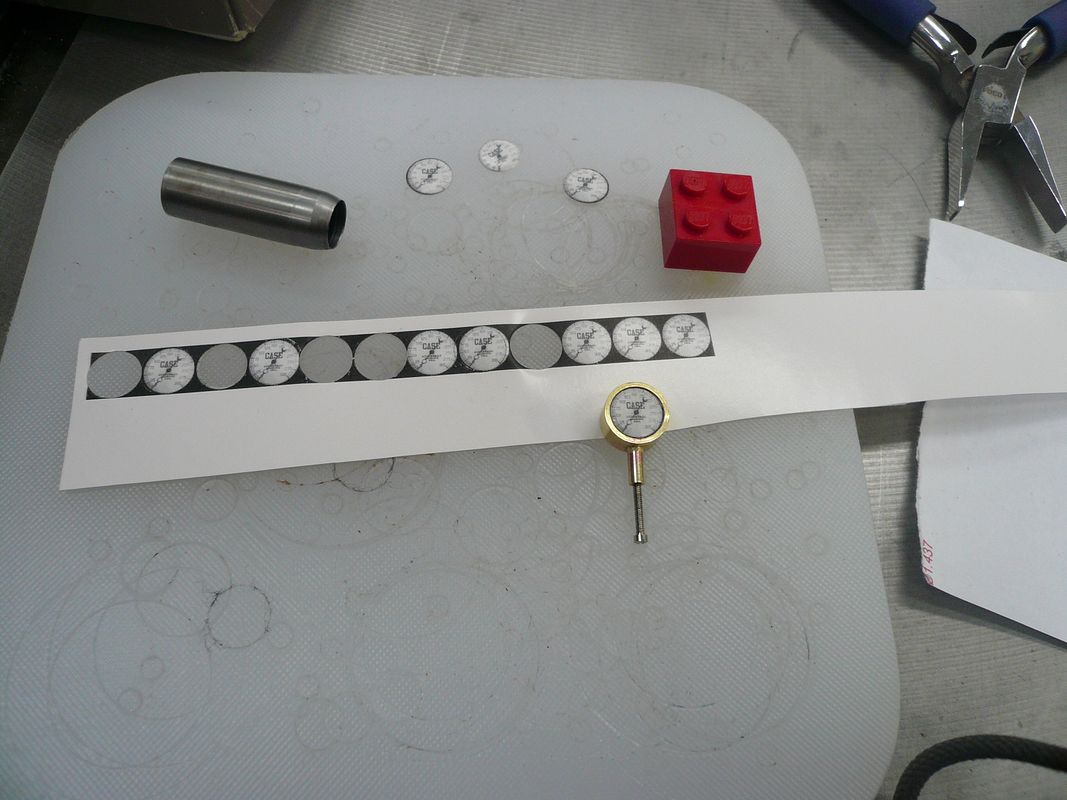

Rudys model has a purely decorative dummy pressure gauge mounted on the steam dome. Its made from 7/16 diameter brass and mounted on a 3/32 standard.

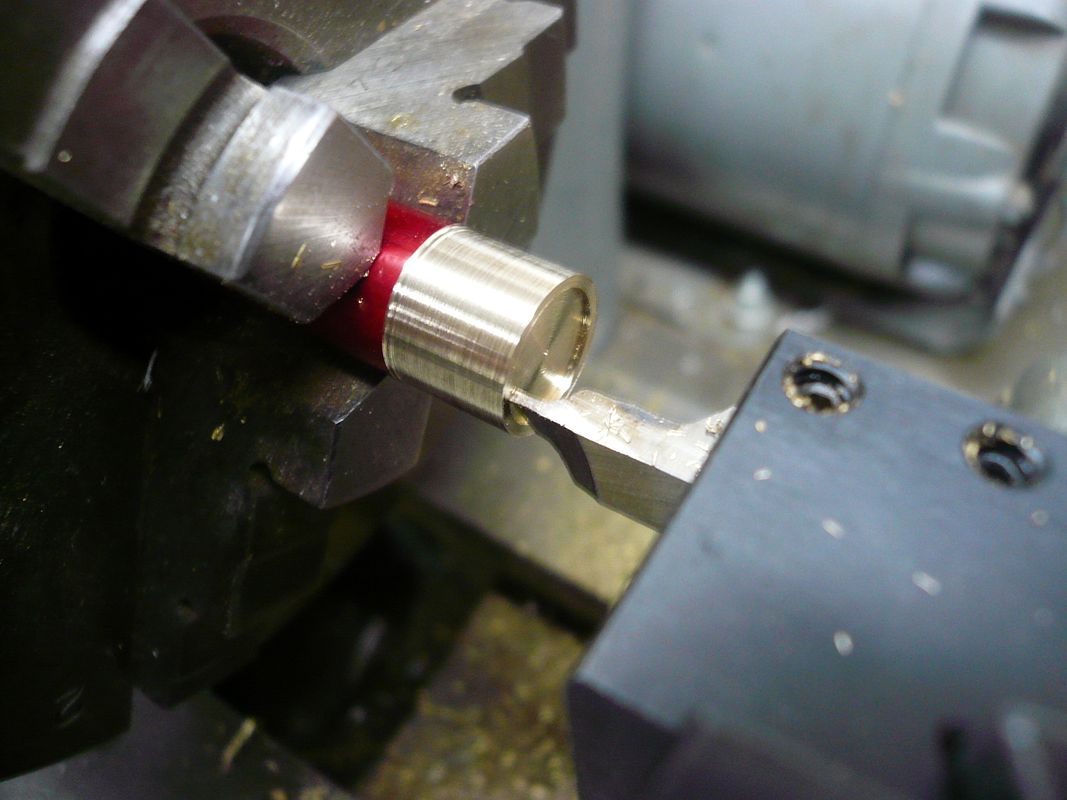

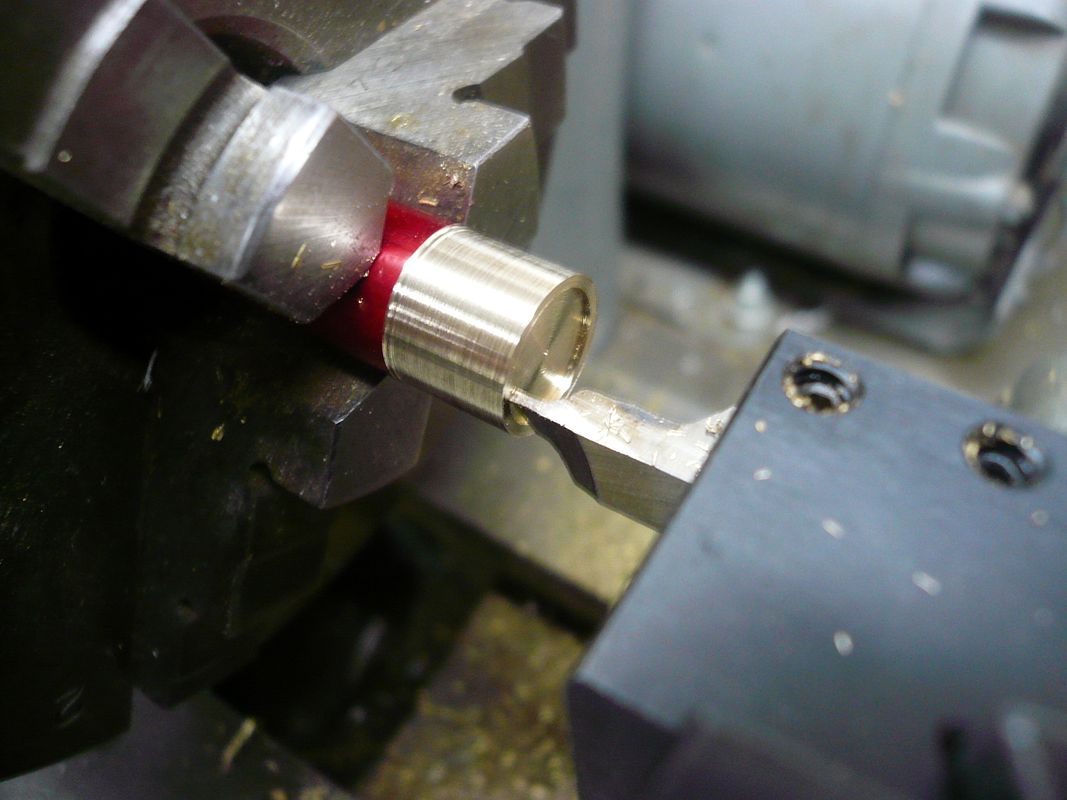

I turned the OD first and then cut a 3/8 diameter recess to represent the dial.

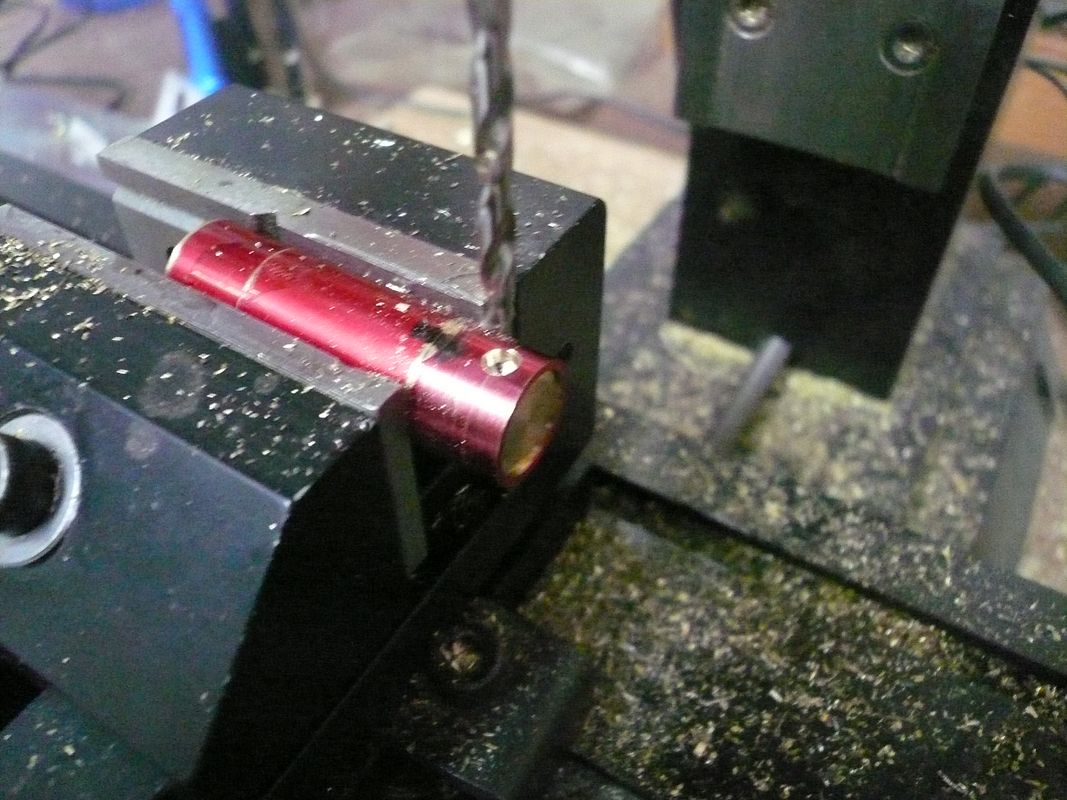

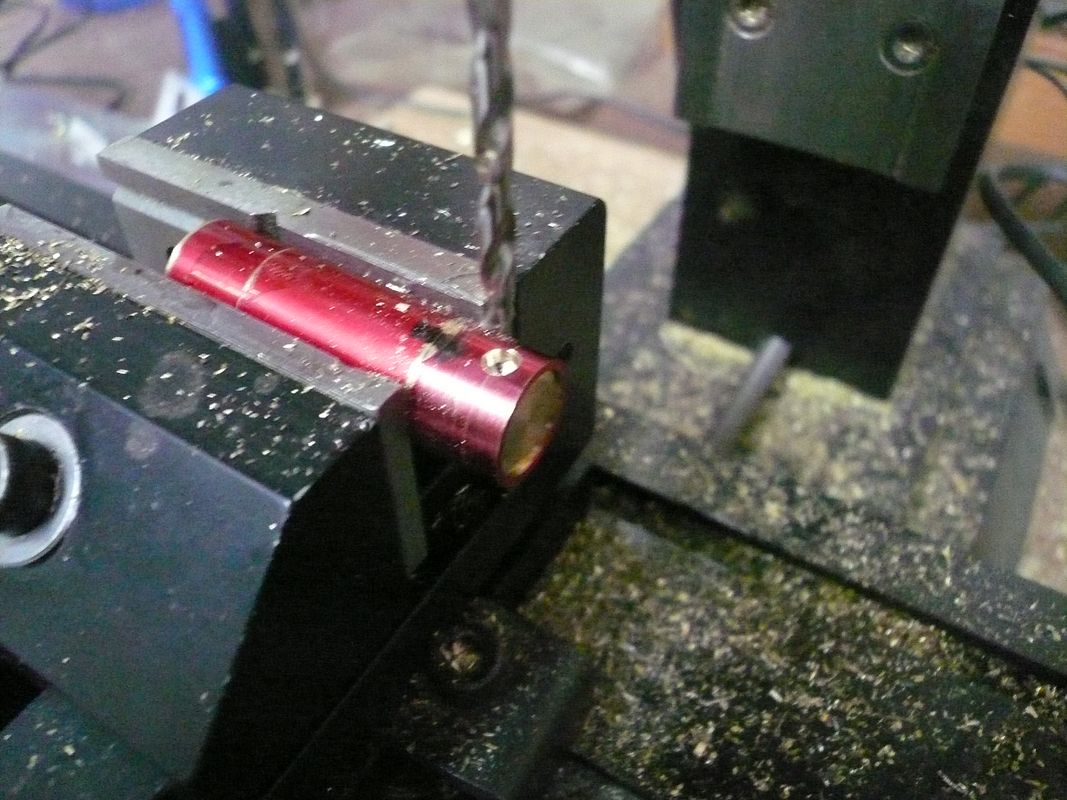

Then cross drilled it 3/32 for the standard,

parted it off and silver soldered in the standard which is a piece of 3/32 rod drilled and tapped 0-80.

Rudy stopped at this point, but I thought Id kick it up a notch using this photo.

I cleaned it up a bit in Photoshop to get this.

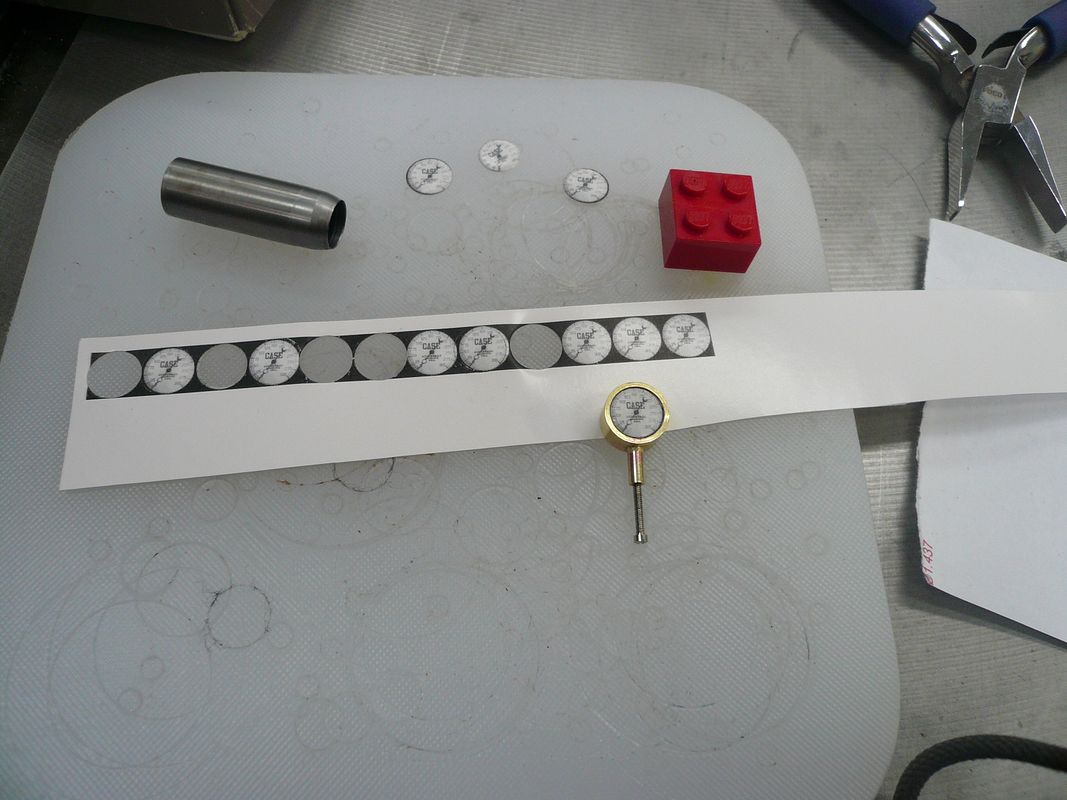

The Photoshopped picture was then printed so the dial face diameter, as printed, was 3/8.

The dial was then cut out using a punch made from a piece of 3/8 ID steel tube. I printed multiple copies of the dial because I assumed (correctly) that it would be tough to get the punch exactly centered.

I had left a slight burr when I cut the recess for the dial, so I just popped the dial in and it seems to be secure.

If anyone wants a higher resolution copy of the dial jpeg, PM me and Ill send you one.

Happy Easter everyone!

Regards,

Dennis

Post #48

Dummy Pressure Gauge

Rudys model has a purely decorative dummy pressure gauge mounted on the steam dome. Its made from 7/16 diameter brass and mounted on a 3/32 standard.

I turned the OD first and then cut a 3/8 diameter recess to represent the dial.

Then cross drilled it 3/32 for the standard,

parted it off and silver soldered in the standard which is a piece of 3/32 rod drilled and tapped 0-80.

Rudy stopped at this point, but I thought Id kick it up a notch using this photo.

I cleaned it up a bit in Photoshop to get this.

The Photoshopped picture was then printed so the dial face diameter, as printed, was 3/8.

The dial was then cut out using a punch made from a piece of 3/8 ID steel tube. I printed multiple copies of the dial because I assumed (correctly) that it would be tough to get the punch exactly centered.

I had left a slight burr when I cut the recess for the dial, so I just popped the dial in and it seems to be secure.

If anyone wants a higher resolution copy of the dial jpeg, PM me and Ill send you one.

Happy Easter everyone!

Regards,

Dennis

Beautifully done Dennis. And here I thought sure you would have put a stop valve plumbed over to a faux governor at the steam chest in that spot. :big: That is one of THE nicest TEs I have seen in a long while.

BC1

Jim

BC1

Jim

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Neat idea and beautiful work.

I sure enjoy looking at your pictures.

I sure enjoy looking at your pictures.

Bernd

Well-Known Member

Nicely done Dennis. Makes it look very realistic.

To bad the gauge didn't read about 250Lbs. :big:

Bernd

To bad the gauge didn't read about 250Lbs. :big:

Bernd

- Joined

- Feb 25, 2008

- Messages

- 464

- Reaction score

- 5

Dean, Zee, Gail, Bernd, Chuck, Arnold & putputman...Thank you for your kind comments.

Thayer...I'm going to you for future Photoshop work.

Jim,

A "stop valve plumbed over to faux governor" crossed my mind, but this is a representational model AND I'd like to finish it in my lifetime!

Post 49

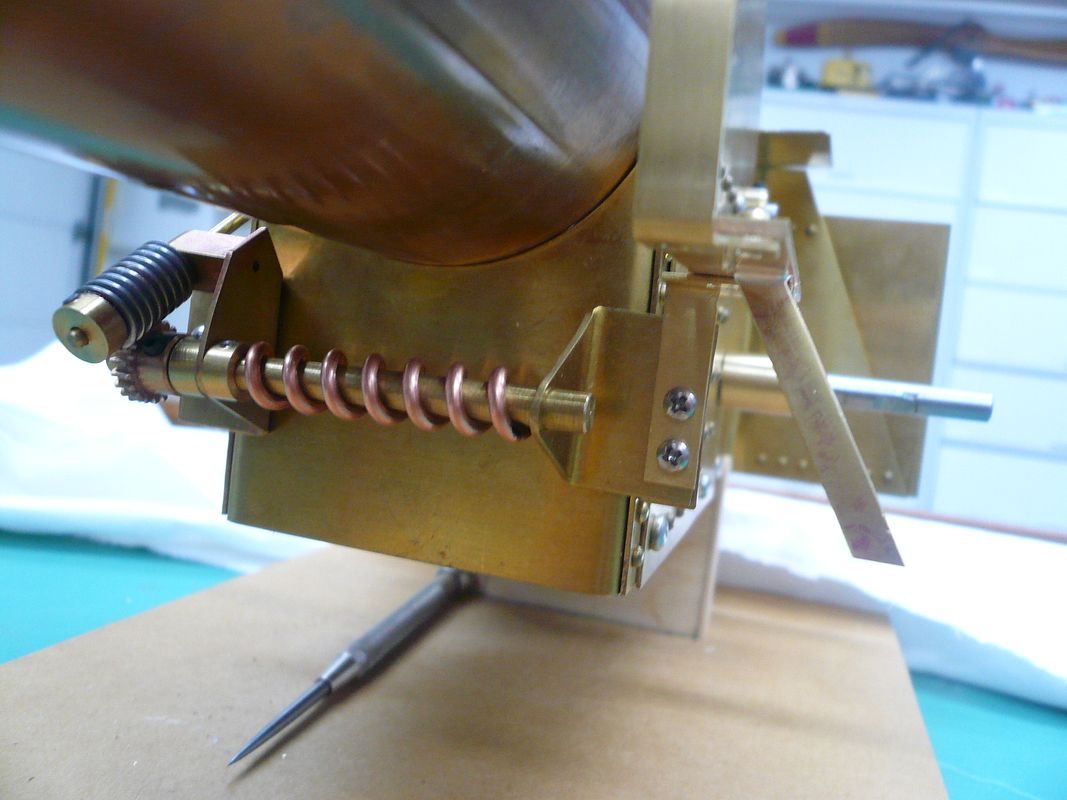

Steering

I made the front axle much earlier in this build, but hadnt provided for a way to attach the steering chains.

The first step is to cut two 1/4 long pieces of 3/8 tubing (5/16 ID) to use as attaching collars. These slip over the axle. Next bend two small rings to serve as chain attachment points and silver solder the rings to the collars.

It took two Third Hand devices to hold things in place.

Then position the collars on the axle and Locktite them in place.

The drill bit helps get the orientation right. As you probably know, any Loctite not in the joint wipes off cleanly after the joint cures.

Finding steering chain I was happy with was a real ordeal. I dont know how many samples I bought from various craft, beading and jewelry supply stores. They were all either; too shiny, too small, too large or too weak. About the time I was ready to compromise, I noticed that Gary Hart (ghart) had what looked like exactly the right chain on his tractor. I PMed him and he said he used clock weight chain. Bingo! Dont know why I didnt think of that.

So, off to the nearest clock repair store. I told the guy what I was looking for and he brought out his junk drawer and let me dig through it. I found exactly what I needed. He said if I wanted more to ask for No. 1 Cuckoo Clock Chain. Link dimensions are 0.145 wide, 0.290 long and its made from 0.033 wire. Six feet for $3 bucks, plus he let me take whatever I wanted from the junk drawer. He was an older gentleman and said mechanical clock repair is a dying business and he would never use up the pieces. Depressing.

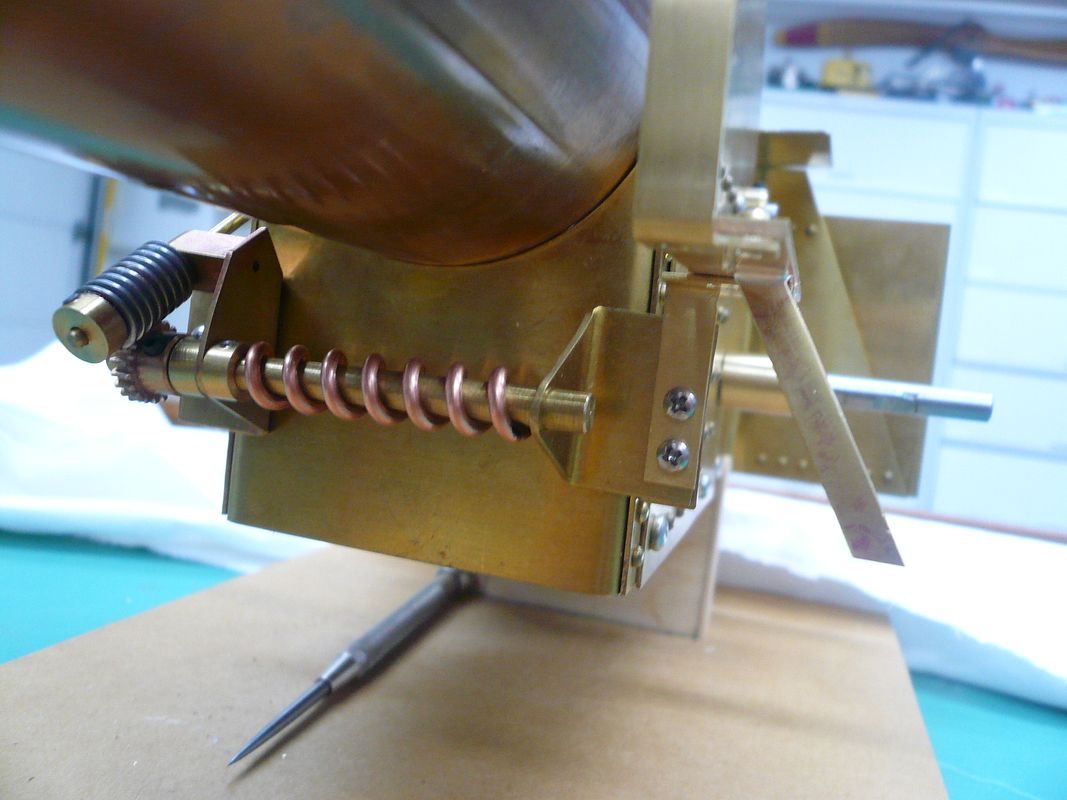

In Garys email he also pointed out that he had added a guide spring to the steering chain roller to keep the chain from tangling. Its a nifty enhancement. Thanks, Gary.

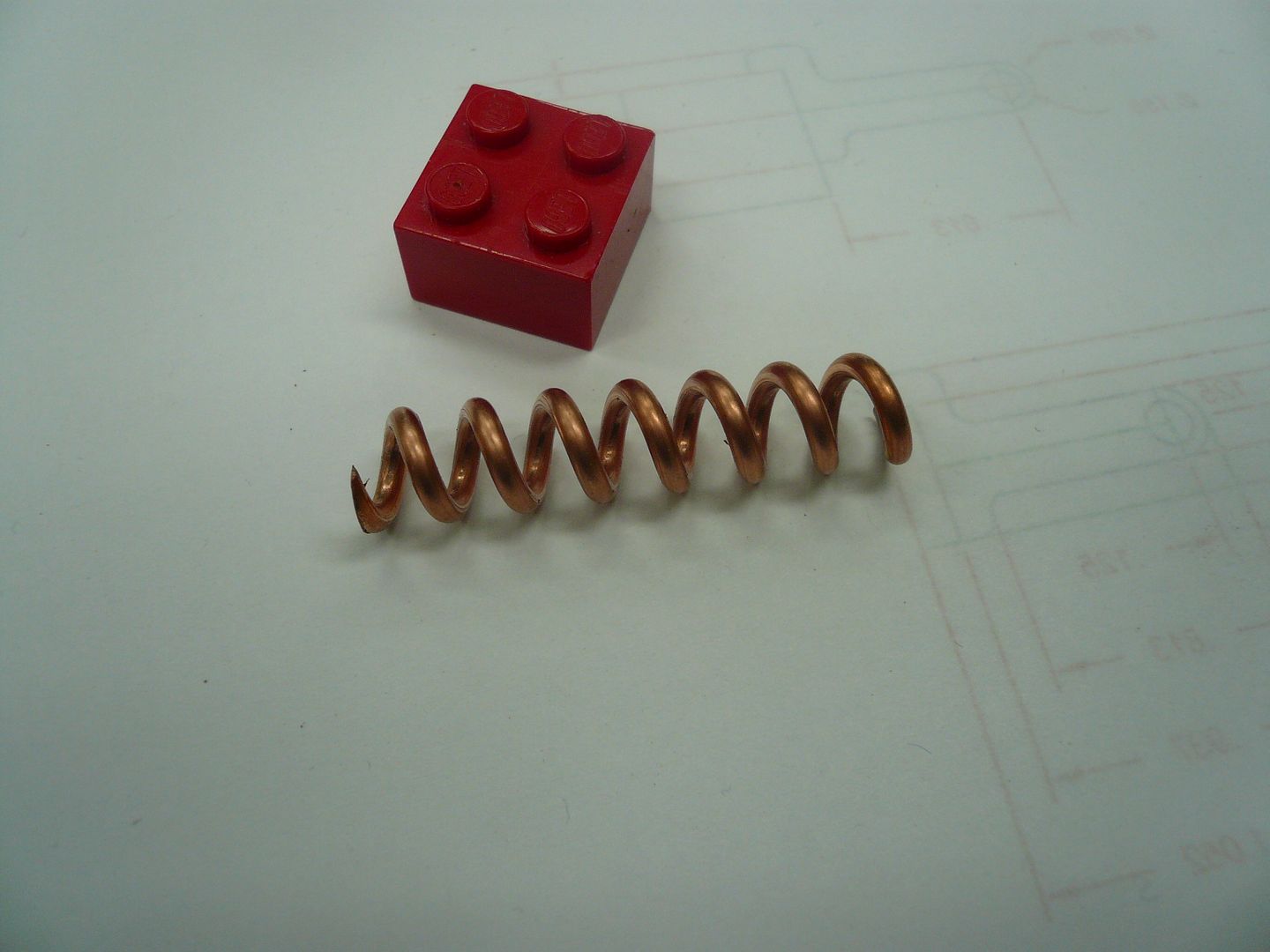

I made my guide out of a piece of 12AWG copper wire. Probably should have been brass, but I didnt have any.

(Note: The spring shown is a right hand one. To steer properly it needs to be left hand. All of the following photos except the last one show right hand springs. Sorry, but by the time I figured this out and how to wind a left hand one, I was too frustrated to retake the photos.)

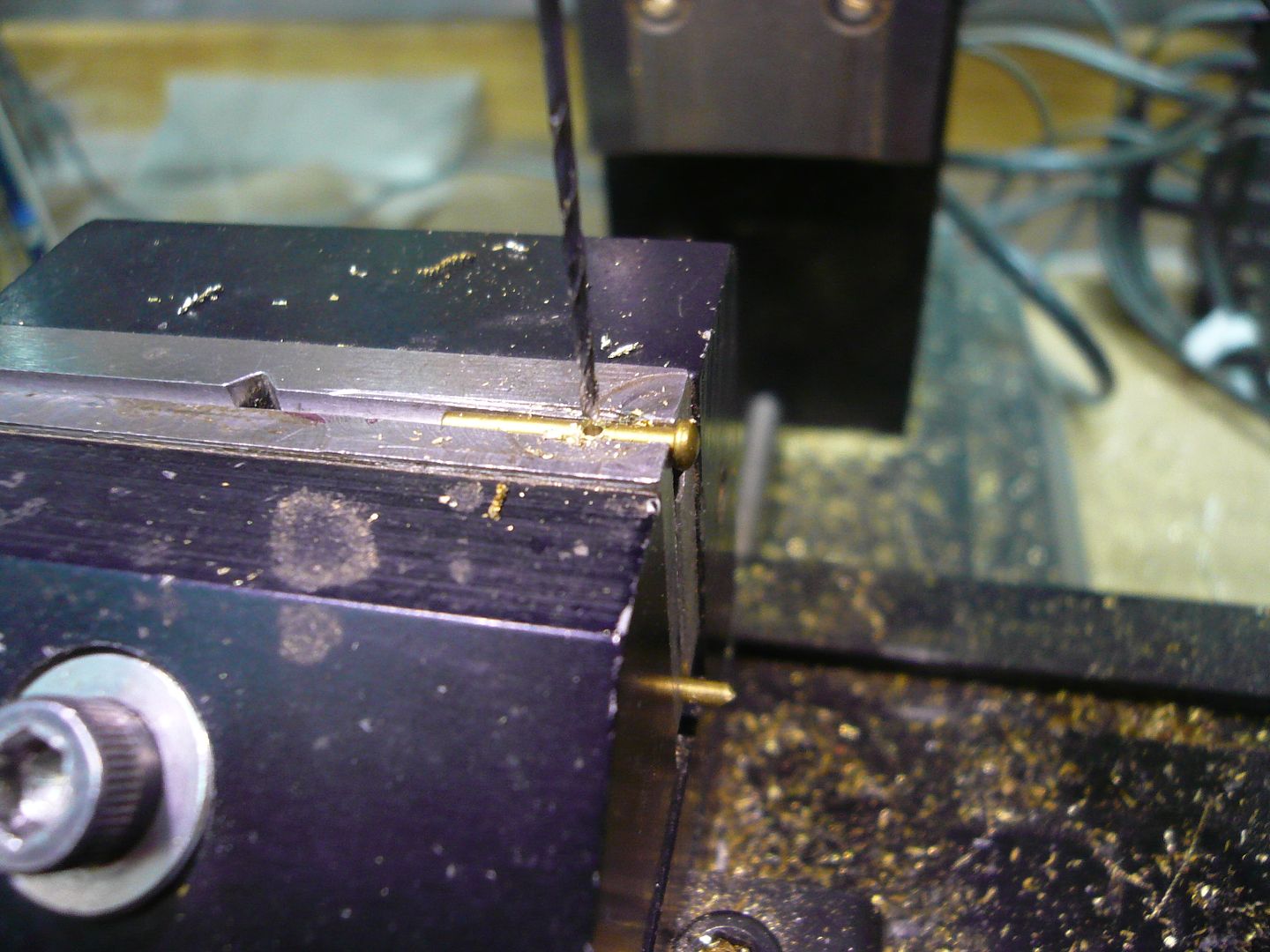

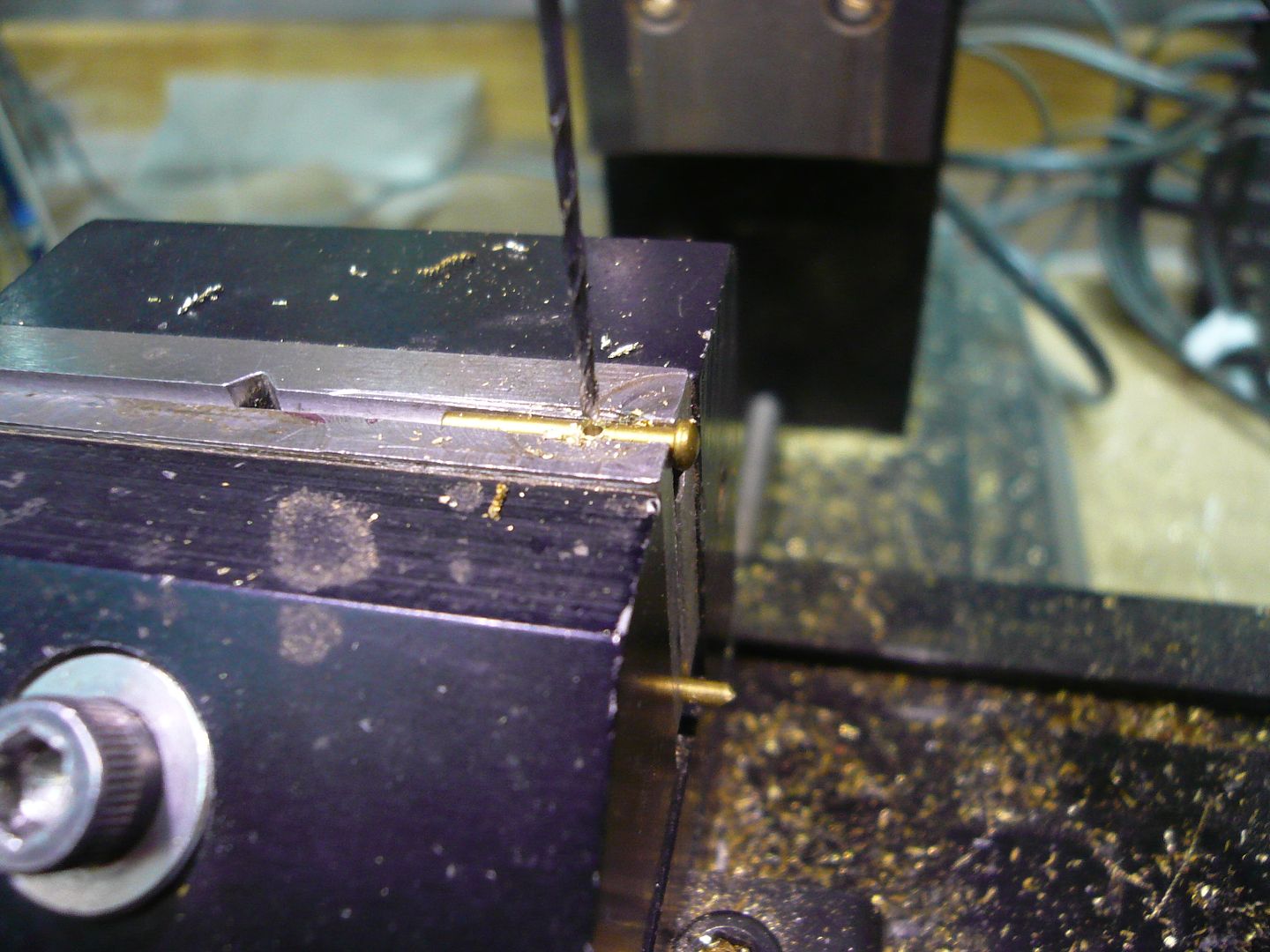

The spring is wound around a 3/16 mandrel. I turned the lathe by hand no power (although it could be powered if you know what youre doing).

The tool Im using is a Hojarth Perfection Spring Winder patented in 1907. Ive had this for years (I collect old tools) and never had occasion to use it before. It seems to work very well.

The tool consists of a handle, a tension adjusting nut, clamp (brass) and a spacing guide (brass). The spacing guide has various thickness lands and it controls the spacing between turns. I picked a land that matched the link width on my chain.

In use, the wire is threaded through guide holes in the handle and between the two brass plates. Feed enough wire through to hook on the chuck and turn the chuck to wind the spring. The amount of tension you put on the star nut determines how tight the spring gets.

Heres an overall shot of the winder.

This one is about 9 long. They came in several sizes. If youd like to know more, Google patent 861,283.

To wind a spring without a Hojarth, check out Deanofids excellent thread, Springs and Things" here

But I digress

It took me numerous tries to figure out that I needed a left hand spring and that turning the lathe backwards doesnt get you one. To get a left hand one, you have to wind from the tailstock chuck toward the headstock. If theres another way, please tell me. At this point, I get a headache just thinking about it.

Anyway, after winding the spring/guide, grind the ends perpendicular to the axis.

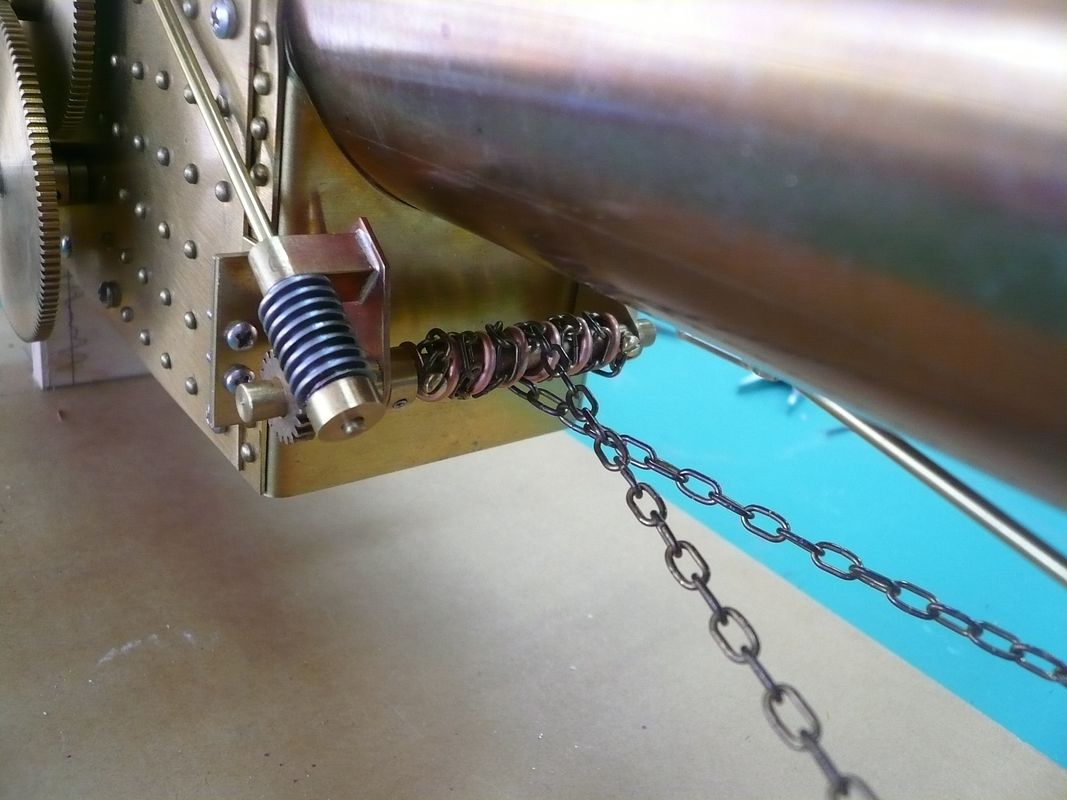

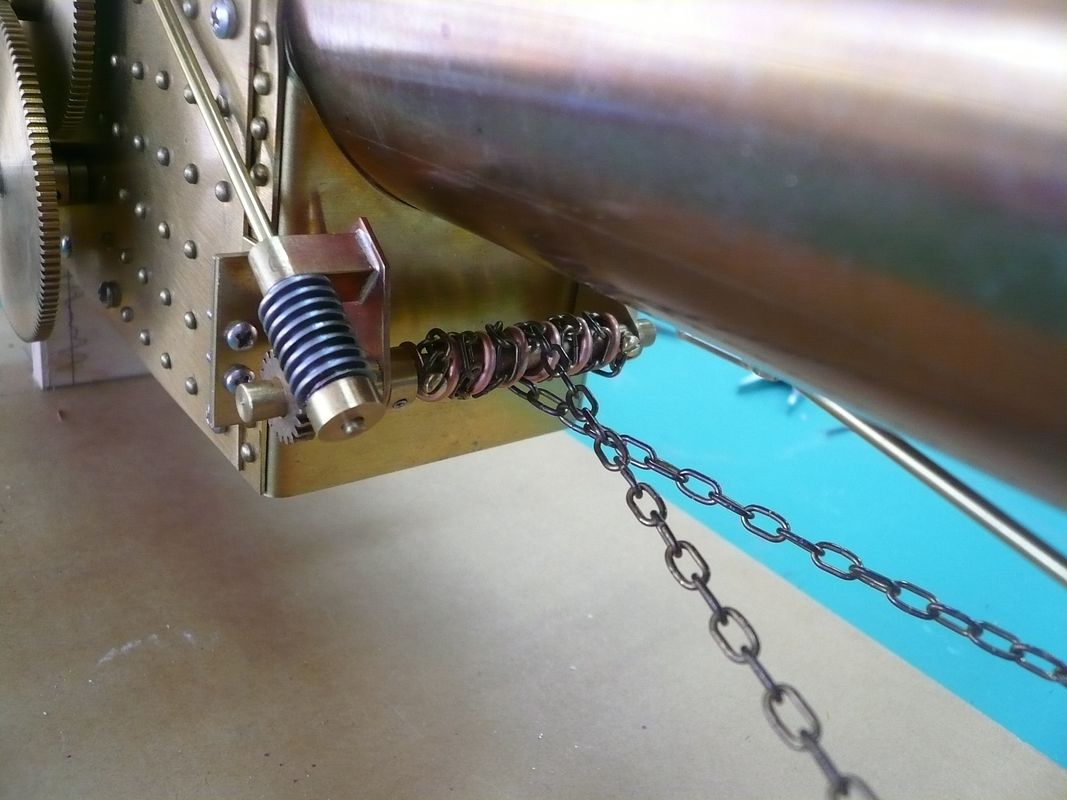

and install it on the steering chain roller and wind on the chain.

This is the first photo with a correctly wound guide. Also note that the chains cross. The guide and the crossed chains are similar to the real Case tractor.

Regards,

Dennis

Thayer...I'm going to you for future Photoshop work.

Jim,

A "stop valve plumbed over to faux governor" crossed my mind, but this is a representational model AND I'd like to finish it in my lifetime!

Post 49

Steering

I made the front axle much earlier in this build, but hadnt provided for a way to attach the steering chains.

The first step is to cut two 1/4 long pieces of 3/8 tubing (5/16 ID) to use as attaching collars. These slip over the axle. Next bend two small rings to serve as chain attachment points and silver solder the rings to the collars.

It took two Third Hand devices to hold things in place.

Then position the collars on the axle and Locktite them in place.

The drill bit helps get the orientation right. As you probably know, any Loctite not in the joint wipes off cleanly after the joint cures.

Finding steering chain I was happy with was a real ordeal. I dont know how many samples I bought from various craft, beading and jewelry supply stores. They were all either; too shiny, too small, too large or too weak. About the time I was ready to compromise, I noticed that Gary Hart (ghart) had what looked like exactly the right chain on his tractor. I PMed him and he said he used clock weight chain. Bingo! Dont know why I didnt think of that.

So, off to the nearest clock repair store. I told the guy what I was looking for and he brought out his junk drawer and let me dig through it. I found exactly what I needed. He said if I wanted more to ask for No. 1 Cuckoo Clock Chain. Link dimensions are 0.145 wide, 0.290 long and its made from 0.033 wire. Six feet for $3 bucks, plus he let me take whatever I wanted from the junk drawer. He was an older gentleman and said mechanical clock repair is a dying business and he would never use up the pieces. Depressing.

In Garys email he also pointed out that he had added a guide spring to the steering chain roller to keep the chain from tangling. Its a nifty enhancement. Thanks, Gary.

I made my guide out of a piece of 12AWG copper wire. Probably should have been brass, but I didnt have any.

(Note: The spring shown is a right hand one. To steer properly it needs to be left hand. All of the following photos except the last one show right hand springs. Sorry, but by the time I figured this out and how to wind a left hand one, I was too frustrated to retake the photos.)

The spring is wound around a 3/16 mandrel. I turned the lathe by hand no power (although it could be powered if you know what youre doing).

The tool Im using is a Hojarth Perfection Spring Winder patented in 1907. Ive had this for years (I collect old tools) and never had occasion to use it before. It seems to work very well.

The tool consists of a handle, a tension adjusting nut, clamp (brass) and a spacing guide (brass). The spacing guide has various thickness lands and it controls the spacing between turns. I picked a land that matched the link width on my chain.

In use, the wire is threaded through guide holes in the handle and between the two brass plates. Feed enough wire through to hook on the chuck and turn the chuck to wind the spring. The amount of tension you put on the star nut determines how tight the spring gets.

Heres an overall shot of the winder.

This one is about 9 long. They came in several sizes. If youd like to know more, Google patent 861,283.

To wind a spring without a Hojarth, check out Deanofids excellent thread, Springs and Things" here

But I digress

It took me numerous tries to figure out that I needed a left hand spring and that turning the lathe backwards doesnt get you one. To get a left hand one, you have to wind from the tailstock chuck toward the headstock. If theres another way, please tell me. At this point, I get a headache just thinking about it.

Anyway, after winding the spring/guide, grind the ends perpendicular to the axis.

and install it on the steering chain roller and wind on the chain.

This is the first photo with a correctly wound guide. Also note that the chains cross. The guide and the crossed chains are similar to the real Case tractor.

Regards,

Dennis

Another great write up and nice clear pics from you, Dennis. I'm starting to sound like a parrot;

"looking good, looking good", but, you know... Looking good!

That's a neat old winder. I wouldn't have known what it was at first sight, but would have bought it, just because of the shapely handle.

Dean

"looking good, looking good", but, you know... Looking good!

That's a neat old winder. I wouldn't have known what it was at first sight, but would have bought it, just because of the shapely handle.

Dean

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Deanofid said:That's a neat old winder. I wouldn't have known what it was at first sight

Dean

Me neither.

Great work Dennis :bow:

Best Regards

Bob

Similar threads

- Replies

- 111

- Views

- 21K