undersize

Member

- Joined

- Feb 8, 2018

- Messages

- 16

- Reaction score

- 1

Following on from my question which first engine? it became clear the Webster would be a good choice.

I am only just past the planning stage with some machining completed.

Cylinder machined and bored needs honing.

Cylinder head frame machined some drilling needed.

Side frame material machined to thickness (from 12mm)

Crankshaft support material machined to thickness (from 12mm)

Carburetor purchased

Piston rings purchased

Spark plug purchased.

OK not a whole lot completed yet but the Webster is in the making.

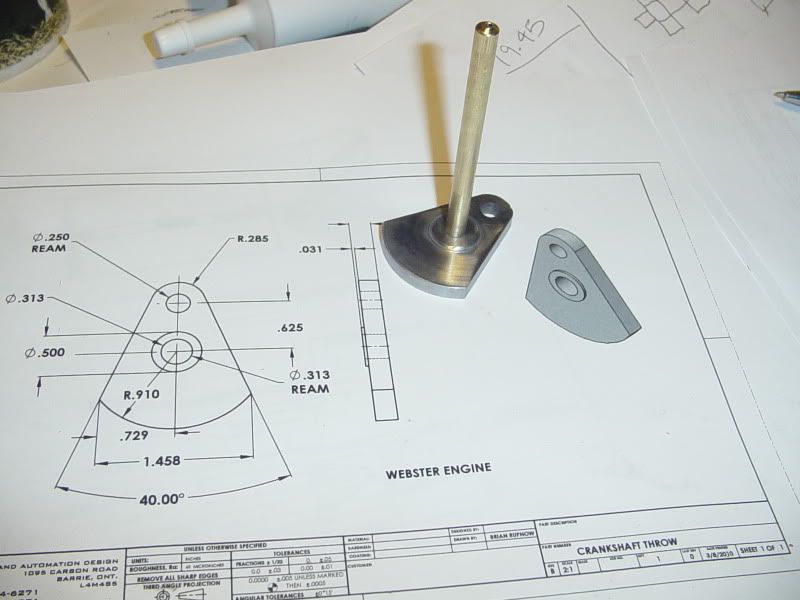

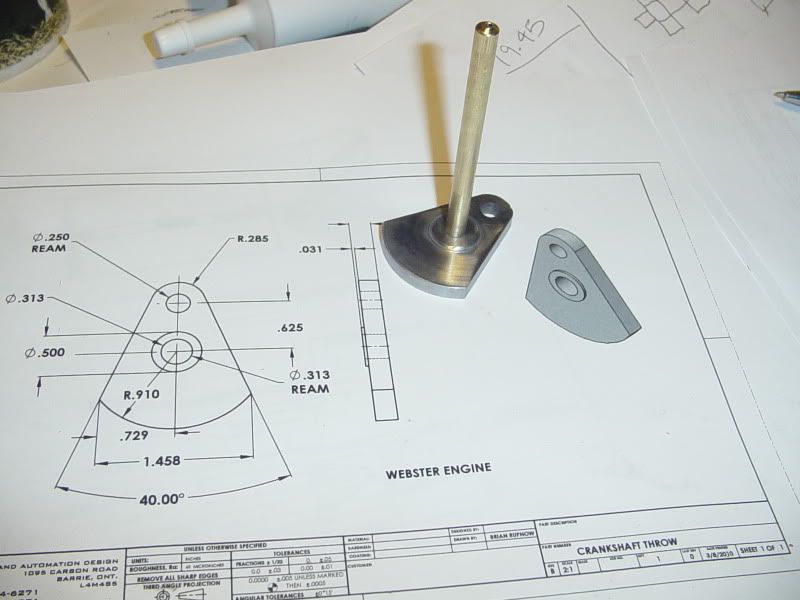

I would like to make the crankshaft in one piece turning between centers including in the design the balance web as Brian Rupnow designed for his.

What spec material would you use I have a Dia 2" X 12" long piece of EN24T what are your thoughts on using this material?

What spec material would you use I have a Dia 2" X 12" long piece of EN24T what are your thoughts on using this material?

I am only just past the planning stage with some machining completed.

Cylinder machined and bored needs honing.

Cylinder head frame machined some drilling needed.

Side frame material machined to thickness (from 12mm)

Crankshaft support material machined to thickness (from 12mm)

Carburetor purchased

Piston rings purchased

Spark plug purchased.

OK not a whole lot completed yet but the Webster is in the making.

I would like to make the crankshaft in one piece turning between centers including in the design the balance web as Brian Rupnow designed for his.