You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Broken frame ford transit

- Thread starter jack09

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BaronJ

Grumpy Old Git.

Hello Jack,

I don't see why not. As long as the metal that you are welding to is sound and the replacement material is at least as thick as the original.

Once it is welded in place a coat of underseal will finish the job and protect the new metal and welds.

It is a bit messy, but I used to spray the old engine oil on the underside. It stinks a bit on the exhaust but that soon burns off.

I don't see why not. As long as the metal that you are welding to is sound and the replacement material is at least as thick as the original.

Once it is welded in place a coat of underseal will finish the job and protect the new metal and welds.

It is a bit messy, but I used to spray the old engine oil on the underside. It stinks a bit on the exhaust but that soon burns off.

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

Hi. Can i use a DC01 or s355 steel for repair cracked Ford Transit frame?

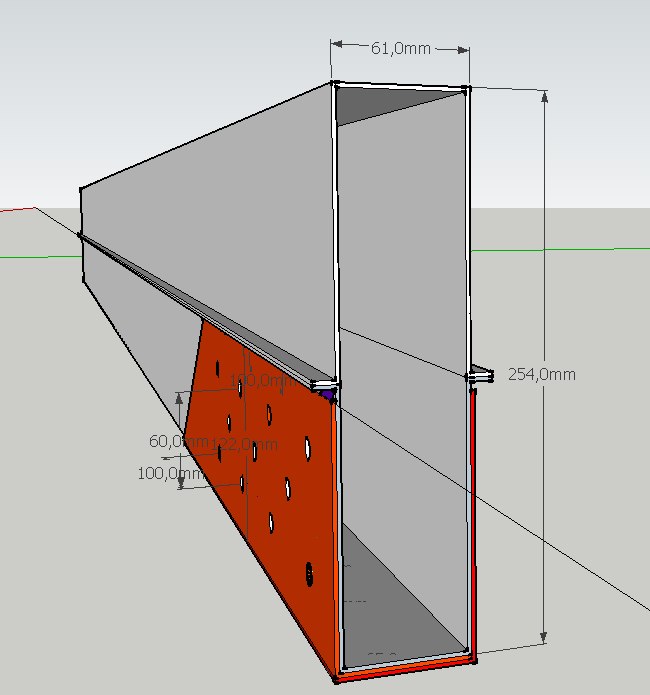

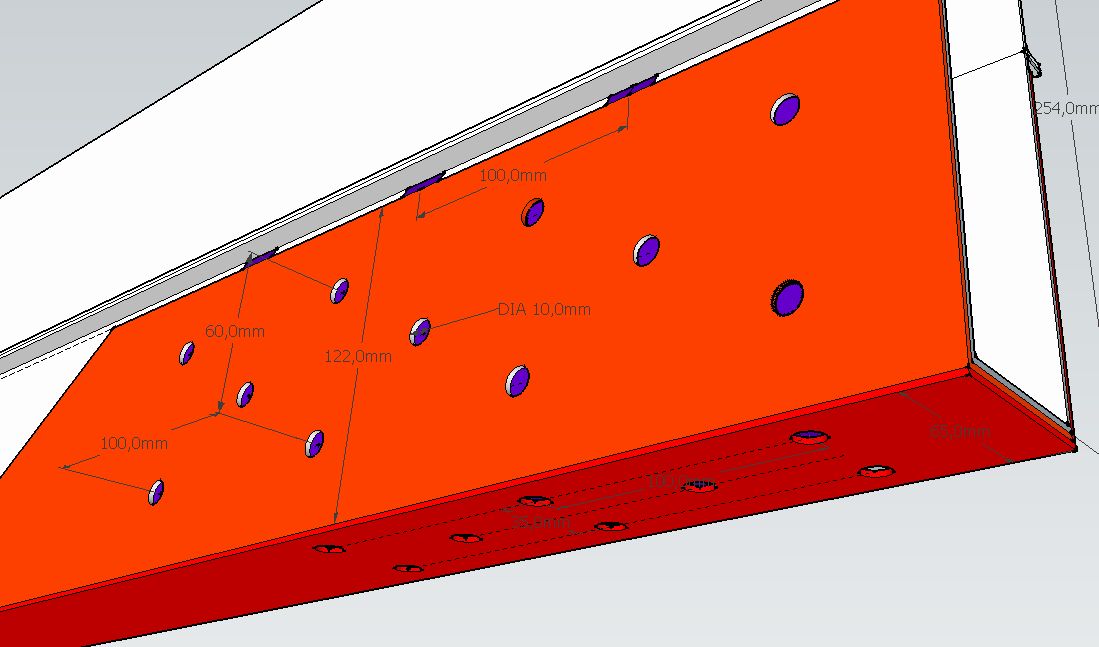

I want to bend 2 angle and weld it to frame

hi I don't know where you live

but in Canada you cant weld a frame not safe enough

but you can bolt it and they are called fish plate

good luck

BaronJ

Grumpy Old Git.

Hi Guys,

That's fine if you access to the inside of the hollow section. Putting long bolts right through is a no no unless there is support between the sides of the frame, ie tubes. You could drill holes right through and weld in some tubes, like they do for the tow bar bolts. However I would argue that they wouldn't be quite as rigid as welded plates as shown in the drawing.

That's fine if you access to the inside of the hollow section. Putting long bolts right through is a no no unless there is support between the sides of the frame, ie tubes. You could drill holes right through and weld in some tubes, like they do for the tow bar bolts. However I would argue that they wouldn't be quite as rigid as welded plates as shown in the drawing.

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

Welded, spliced and repaired many truck frames large and small. Never a problem. Clean , common sense , and a decent weld. No problem.

I have a s6a licence and for safety check it's a NO NO

Jack,

Have you checked with your dealer or someone knowledgeable about the steel used in your particular frame? The low carbon steel frames used in older vehicles were easily weldable, but auto makers today sometimes make use of high-strength low-weight alloys, and the Transit may be one of them. Some high strength alloys are prone to cracking after any welding, some require heat treatment afterwards, and some require special the use of special filler metals. I've seen some frames on commercial vehicles that were stamped with the warning "No Welding on Frame." - Terry

Have you checked with your dealer or someone knowledgeable about the steel used in your particular frame? The low carbon steel frames used in older vehicles were easily weldable, but auto makers today sometimes make use of high-strength low-weight alloys, and the Transit may be one of them. Some high strength alloys are prone to cracking after any welding, some require heat treatment afterwards, and some require special the use of special filler metals. I've seen some frames on commercial vehicles that were stamped with the warning "No Welding on Frame." - Terry

Last edited:

goldstar31

Well-Known Member

Mayhugh1's comments are those of that were drilled into me when I did my City and Guilds Motor Vehicle Restoration Certificate- when the dodo laid eggs.

As Alan Robinson's the author( and my tutor) of 'the Repair of Vehicles Bodies' commented on oxy/acetylene at the time, 'You don't know when it is going to crack- but it will'

Again, vehicle bodies are no longer put together to be ' Brick toilets' but the number of spot welds are designed to progressively tear rather than our much more tearable ones.

Regards

Norman

As Alan Robinson's the author( and my tutor) of 'the Repair of Vehicles Bodies' commented on oxy/acetylene at the time, 'You don't know when it is going to crack- but it will'

Again, vehicle bodies are no longer put together to be ' Brick toilets' but the number of spot welds are designed to progressively tear rather than our much more tearable ones.

Regards

Norman

Swifty

Well-Known Member

Noticed stencilled on a lot of truck chassis', DO NOT WELD.

Paul.

Paul.

Jack,

Have you checked with your dealer or someone knowledgeable about the steel used in your particular frame? The low carbon steel frames used in older vehicles were easily weldable, but auto makers today sometimes make use of high-strength low-weight alloys, and the Transit may be one of them. Some high strength alloys are prone to cracking after any welding, some require heat treatment afterwards, and some require special the use of special filler metals. I've seen some frames on commercial vehicles that were stamped with the warning "No Welding on Frame." - Terry

Its a Transit mk5 from 1994

I took of a tank from the frame and grind off the crack and it look like the ex owner done a ****ty job, it doesn't look so bad i was thinking

goldstar31

Well-Known Member

Exactly as predicted- a crack alongside the weld. High strength low alloy niobium steel.

Norman

Norman

I had an Old ford transit back in the late 70s with that horrible V4 engine and a mattress in the back and a sign on the back door that said

If its Rocking Dont Bother Knocking . Many a time it was used to rescue brit bikes that had broke down.

If its Rocking Dont Bother Knocking . Many a time it was used to rescue brit bikes that had broke down.

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

What about putting some rectangular tube inside the frame and through bolting that.

- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

Stregthen with steel sections where you can.Bolt and bronze weld/braze

A combination of mechanical fixings and brazing always worked for me

A combination of mechanical fixings and brazing always worked for me

Similar threads

- Replies

- 18

- Views

- 1K

- Replies

- 57

- Views

- 9K

- Replies

- 13

- Views

- 628

- Replies

- 15

- Views

- 1K