There is more to life than getting "a good deal."

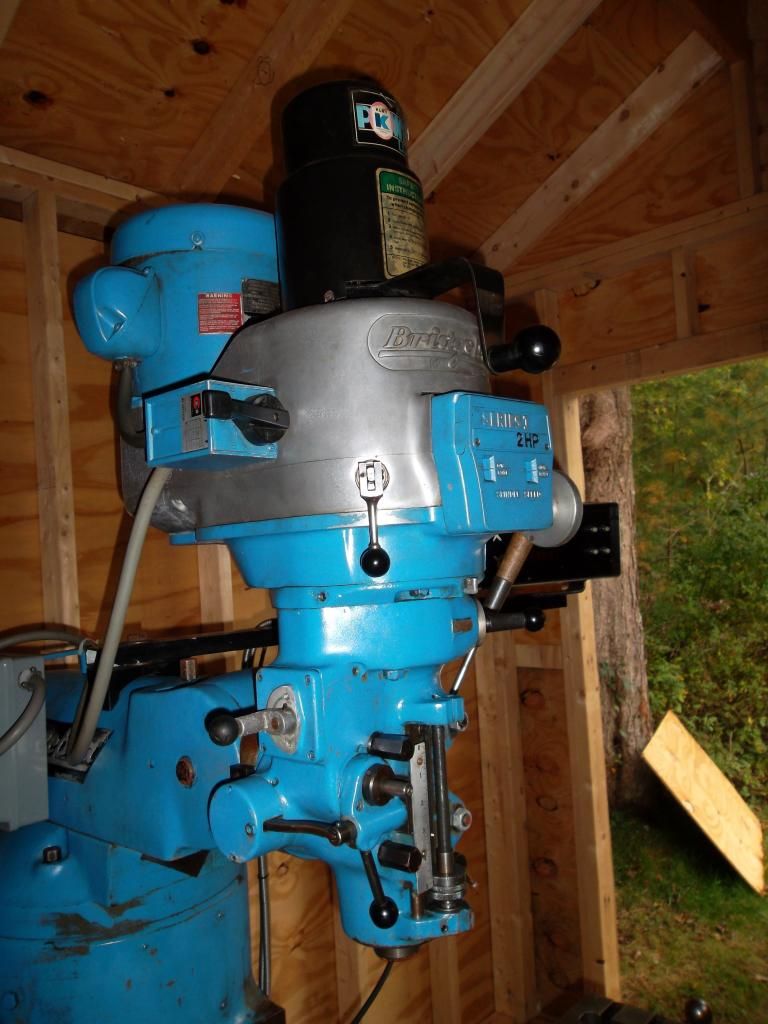

Assuming the machine is in good condition, and it probably is, $5K may be a bit high but not totally outrageous. Other B'ports in other places may be had for cheaper, but you have a chance to buy THIS one that includes delivery and installation. I assume the DRO is a well-known brand, Acu-Rite or similar. That's over a thousand bucks of value. How much is a power drawbar? $500? How much would it cost to hire a rigger to move it?

How much is the machine worth to YOU? That is all that matters. Be aware that in 20 years the fact that you paid $5k or $4k won't matter a bit. Amortized over 20 years, an extra grand is 50 bucks a year. That's one dinner at a nice-ish restaurant per year. Even in 1 year, you won't care what you paid.

You can always dicker politely: "Is there any chance you can come down a bit on the price? I'd really like to buy it, but my budget is limited. $5000 is probably fair, but it would be quite a stretch for me to come up with that much."

Assuming the machine is in good condition, and it probably is, $5K may be a bit high but not totally outrageous. Other B'ports in other places may be had for cheaper, but you have a chance to buy THIS one that includes delivery and installation. I assume the DRO is a well-known brand, Acu-Rite or similar. That's over a thousand bucks of value. How much is a power drawbar? $500? How much would it cost to hire a rigger to move it?

How much is the machine worth to YOU? That is all that matters. Be aware that in 20 years the fact that you paid $5k or $4k won't matter a bit. Amortized over 20 years, an extra grand is 50 bucks a year. That's one dinner at a nice-ish restaurant per year. Even in 1 year, you won't care what you paid.

You can always dicker politely: "Is there any chance you can come down a bit on the price? I'd really like to buy it, but my budget is limited. $5000 is probably fair, but it would be quite a stretch for me to come up with that much."