I had been told by several rebuilders that the Bridgeport oiling system left something to be desired so I decided to make some modifications after receiving my rebuilt quill assembly with instructions to keep the oil off the sealed bearings as it seeps into them and ruins them. In addition, I was told that the lubrication system did not adequately distribute the oil. So, I decided to make a few modifications.

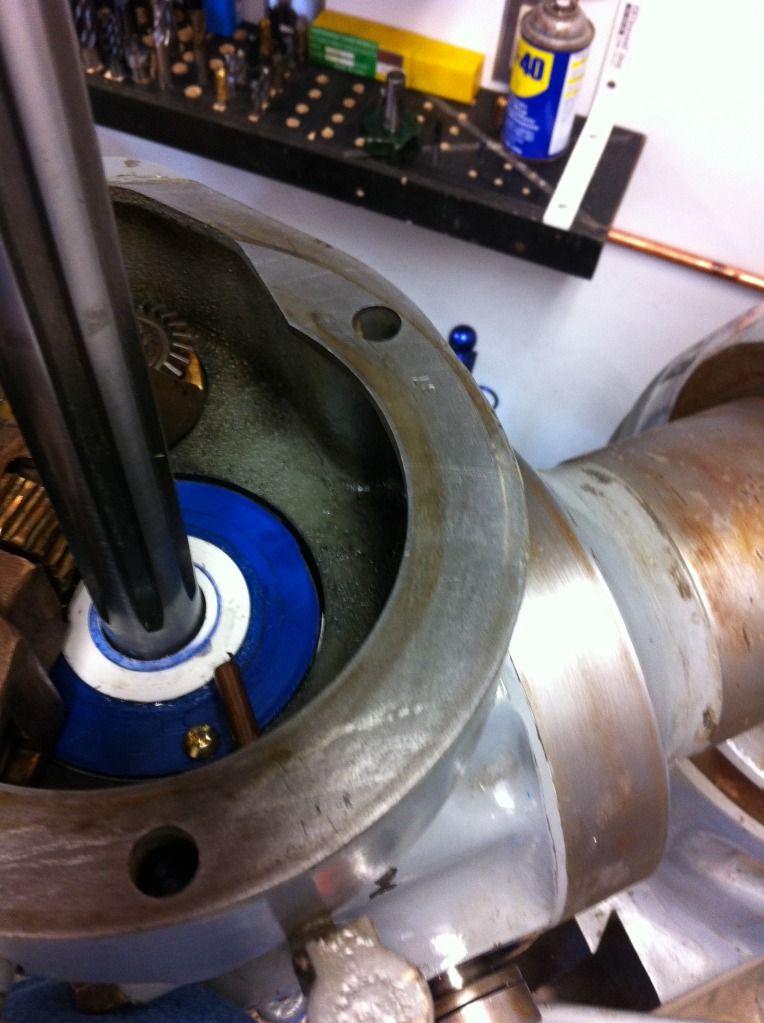

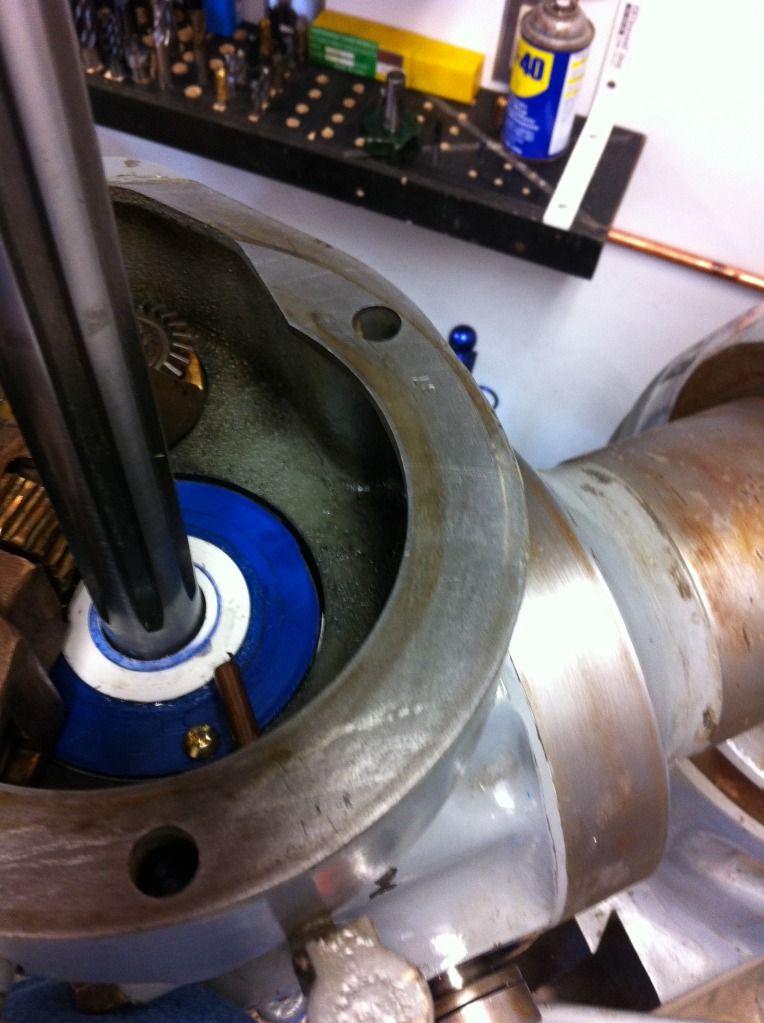

I modified the end of the quill to keep oil out of the sleeve and quill bearings. I turned an old nylon gear (blue) down to fit and made am insert (white) on my lathe and attached it to the end of the sleeve sealing it with silicone.

It is shown here inserted into the quill body.

Finally, I shortened the tube on the lubrication cup.

The job was still not finished because oil could run down the splined shaft so I added an oil slinger (see black washer)

So, to this point I should have eliminated most of the oil going down into the quill bearings. I wanted to provide some point lubrication for the feed gears and bearings so I drilled and tapped a 1/8" NPT thread where I could insert an oil tube to the right length (I recorded these for the future).

I will write myself a letter of lubrication instructions since all of this will be enclosed and hope I can keep everything well lubricated in the future.

Jim

I modified the end of the quill to keep oil out of the sleeve and quill bearings. I turned an old nylon gear (blue) down to fit and made am insert (white) on my lathe and attached it to the end of the sleeve sealing it with silicone.

It is shown here inserted into the quill body.

Finally, I shortened the tube on the lubrication cup.

The job was still not finished because oil could run down the splined shaft so I added an oil slinger (see black washer)

So, to this point I should have eliminated most of the oil going down into the quill bearings. I wanted to provide some point lubrication for the feed gears and bearings so I drilled and tapped a 1/8" NPT thread where I could insert an oil tube to the right length (I recorded these for the future).

I will write myself a letter of lubrication instructions since all of this will be enclosed and hope I can keep everything well lubricated in the future.

Jim