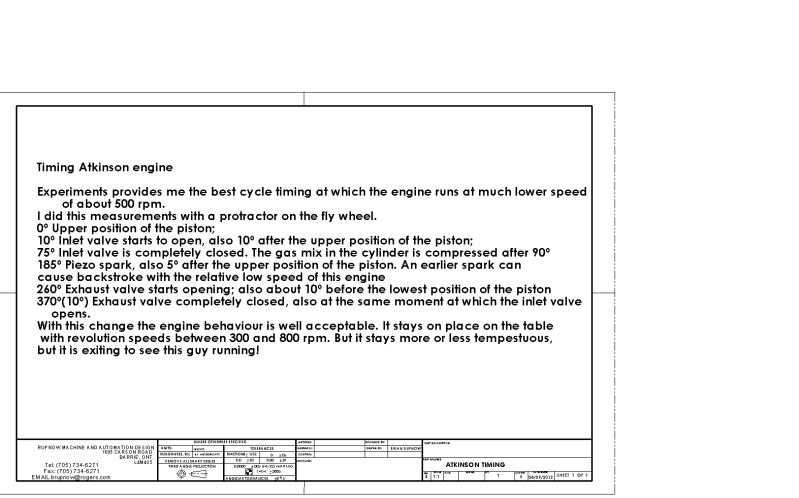

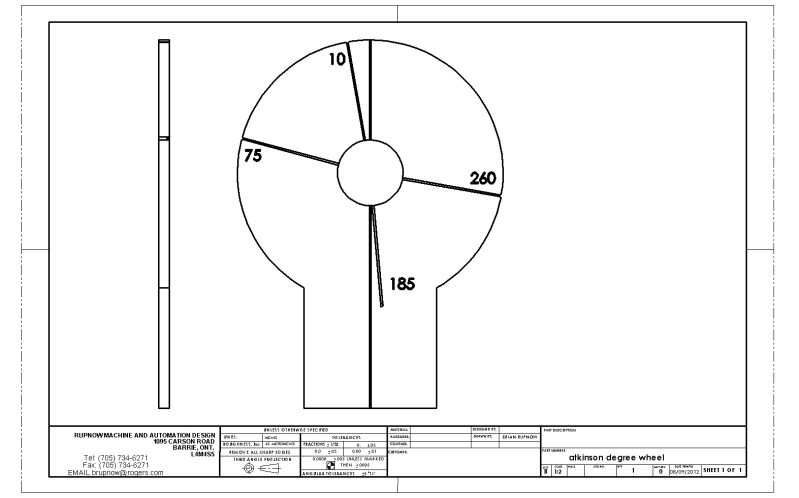

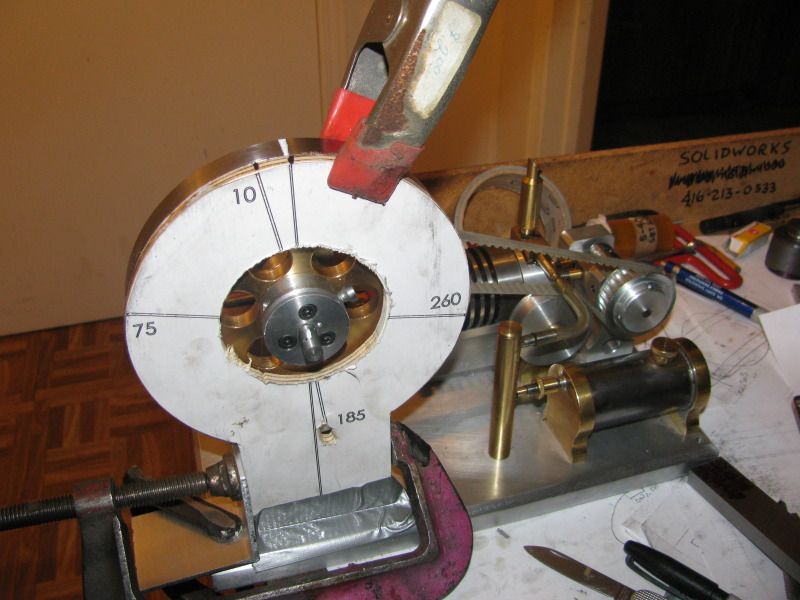

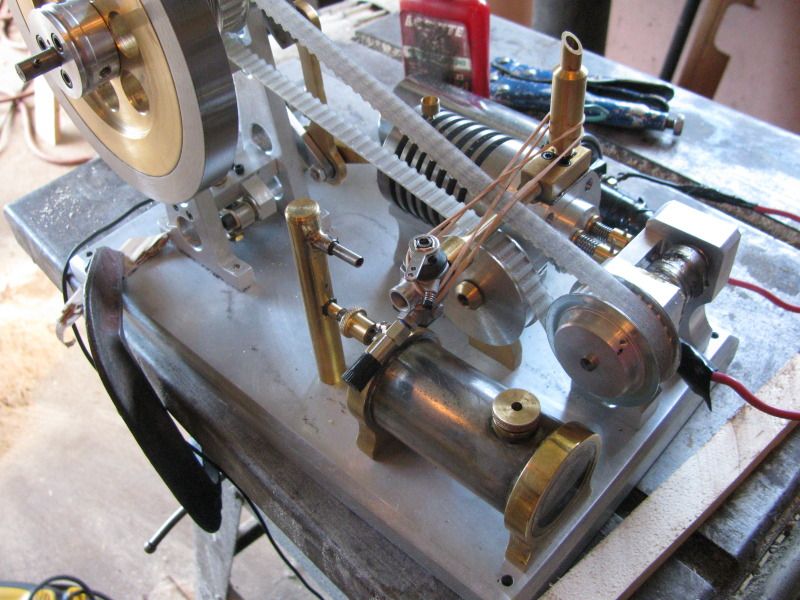

I must say, the timing was amazingly easy. That bit of white-out on top of the flywheel was set with the piston at top dead center. Since the flywheel is only held with 3 set-screws, I also used a centerpunch to "dimple" a spot on top of the crank arm. I advanced the flywheel counterclockwise untill the white mark was in line with the ten degree line, and turned the inlet cam until it was just putting pressure on the inlet valve, then locked down the set screws in the cam. I then advanced to the 75 degree line and checked to see if the intake valve was fully closed. (it was).Then I aligned the white mark with the 185 degree line (seen through the hole) and rotated the spark timing cam until it was up against the rubbing block on the ignition points, ready to open them and then locked it down with the set screws in it. I kept rotating untill the white mark was ligned up with the 260 degree line and set the exhaust cam to a point where it was starting to exert pressure on the stem of the exhaust valve and locked it down. Then I kept rotating untill the white line was once again lined up with the 10 degree line and checked to see if the exhaust valve was fully closed (it was). After that, I slowy rotated the flywheel through one complete revolution, and forgetting about the crazy action of the Atkinson engine I checked to see if the valves, ignition points, and piston were in the relative position and sequence I would expect them to be on a normal 4 cycle engine, and they were right on. ---Hope I've done this all correctly!!!