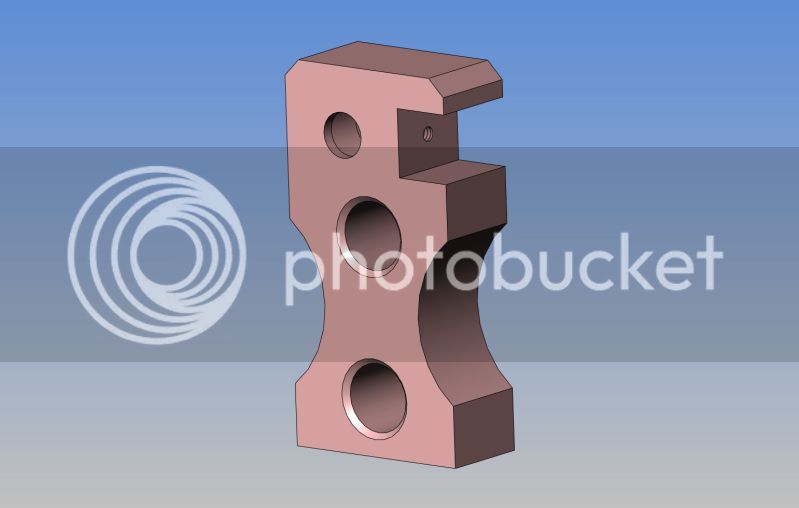

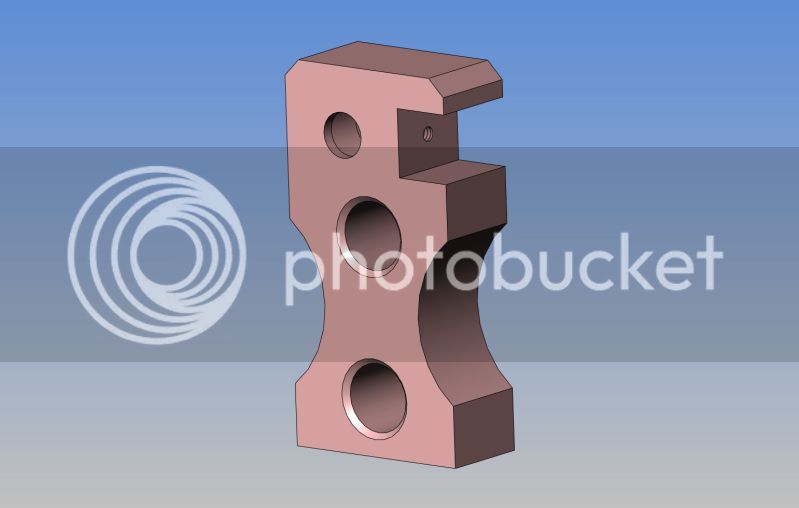

Here we go with the cam shaft stands. Those scallops out of the sides look pretty, but there is a fair amount of set up and machining involved in them. I am using one peice of bar and working from both ends.

Last edited: